Analyzing Membrane Fouling with Atomic Force Microscopy

Published on by Water Network Research, Official research team of The Water Network in Academic

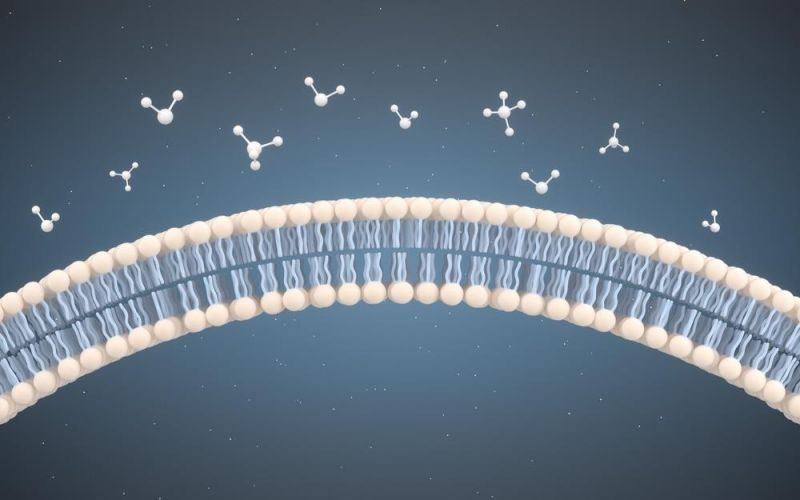

Membrane fouling occurs when insoluble contaminant material is deposited on the membrane surface or within membrane pores, and this can cause deterioration. This article explores how AFM is utilized to analyze membrane fouling.

membrane, membrane fouling, microscopy, atomic force microscopy, AFM Image Credit: Vink Fan/Shutterstock.com

This process is typically a result of precipitation and deposition of molecules or particulates on the surface or pores of membranes. This ultimately causes an increase in membrane separation resistance, reduced productivity as well as altered membrane selectivity.

Membrane fouling can cause problems with applications such as water cleaning processes and so the use of atomic force microscopy to analyze membrane fouling could potentially aid with strengthening the membranes against chemical and physical challenges. This will be further explored in this article.

Background

The production of ultra-pure water has been involved in the use of seawater desalination through reverse osmosis and membrane separation technology. However, this process can also result in membrane fouling, which hinders the initial purpose of generating ultra-pure water.

Membrane fouling, which comprises a large amount of insoluble material from raw water contaminants covering the membrane surface or within the pores, can cause technical problems such as higher pressure being required, increased need for cleaning processes, and lower quality water.

One of the largest contributors to membrane fouling includes microbial biofilm formation, and this can aid in the deterioration process of membranes with fouling, shortening their lifespan.

However, the prevention of membrane fouling has been a focal point in water treatment as well as wastewater treatment. This can include chemical or backwashing, but these also have drawbacks such as aging the membrane and can themselves result in a shorter lifespan. The requirement for controlling and inhibiting microbial biofilm membrane fouling has led researchers to find innovative solutions.

Dr. Chris Wright and his research team from Swansea University, UK, have recently published research on desalination, with the aim of understanding the fouling mechanism further. This research team studied the topic of biofouling and the mechanical properties of virgin and fouled membranes through the use of Atomic Force Microscopy (AFM).

AFM is considered to be a high-resolution technique that is able to be used for a wide range of sample types including thick film coatings, glass, composites, biological and synthetic membranes, microorganisms, and biomaterials. This method can provide information about a sample including physical topography and measurements of physical, chemical, or magnetic properties.

The analysis of the membranes consisted of using an AFM colloid probe technique that aimed to determine the mechanical properties of the membrane, as well as the adhesion forces and work of adhesion at membrane surfaces.

This essential tool can be used to optimize separation processes through further insight into fouling mechanisms; AFM can produce high-resolution images of the membrane surface within certain environments, as well as quantify the forces acting on the membrane surface that result in membrane fouling.

These forces are measured as a function of distance when a probe is attached to the AFM cantilever and makes contact with the sample before retracting. The deflection of the cantilever can be monitored and converted into force values through the use of Hook’s law.

The significance of retrieving force measurement data such as through a force-distance curve using AFM can provide integral information on interaction forces as well as local material properties including elasticity, adhesion, surface charge densities, and hardness. This can indicate the resilience of the membrane to chemical and physical processes as well as illustrate what type of membranes have the highest efficacy; a harder polymer membrane can have reduced wear during operation and cleaning cycles in comparison to softer membranes.

Taxonomy

- Membranes

- RO & MSF Fouling

- Membrane