Aquisense CEO got COVID-19. He realized his business could help fight the pandemic.

Published on by Water Network Research, Official research team of The Water Network in Case Studies

Hannah Week and Daniel Craig work on the electronic assembly for the PearlAqua Micros, the world's smallest UV disinfection system, at AquiSense Technologies on Tuesday, April 7, 2020 in Erlanger, Kentucky. Meg Vogel/ The Enquirer

Oliver Lawal wished he knew exactly where he contracted COVID-19.

Around the time that international cases were confirmed, the Erlanger resident traveled for business to Japan, Taiwan and China. In February, he bounced from India to Orlando for an infectious disease control conference and then to Baltimore. By mid-March he felt the symptoms of the highly contagious upper respiratory disease, couldn’t stop thinking about all the hands he shook and received a positive COVID-19 test result.

Now, as he recovers at home, he wants to help the healthcare workers who helped to diagnose him.

Oliver Lawal stands for a portrait in his home in Walton, Kentucky on Tuesday, April 7, 2020, He is the President and CEO of AquiSense Technologies, which specializes in cleaning water, air and surfaces with UVLED technology. Lawal tested positive for COVID-19 in mid-March. His company is now developing UVLED light boxes that disinfect N95 masks to help healthcare workers reuse the masks.

Meg Vogel/ The Enquirer

“It really dawned on me that we can actually help here,” Lawal, 49 , said in the accent of his native Nottingham, England.

Lawal’s company, AquiSense Technologies, has been around for five years and specializes in cleaning water, air and surfaces with Ultraviolet Light-emitting diode technology, known as UV LED technology. Before he started his own company, he spent decades in the UV LED water treatment business.

This kind of technology uses light waves to clean things like phones, ipads and toothbrushes, Lawal said. His products range from light filters to fix onto sink faucets to projects with the National Aeronautics and Space Administration and the European Space Agency as well.

AquiSense is expanding its production capabilities during the new coronavirus pandemic. They are doubling the size of their cleanroom and hiring new production team members to meet the increased demands for UV disinfection products. AquiSense is based in Erlanger, Kentucky.

Meg Vogel/ The Enquirer

It’s kind of like a microwave, Lawal said, but these light waves are on a different wavelength

Lawal read about healthcare workers’ struggle to obtain enough personal protective equipment to treat and test people with COVID-19. He fixated on the shortage of N95 masks, which healthcare workers wear to block droplets of coronavirus, which causes the disease COVID-19.

Within a week, Lawal’s team took 15 years of experience and connections in the UVLED business world to design, develop and mail lightboxes called the PearlSurface 24G8 that can disinfect three masks at a time.

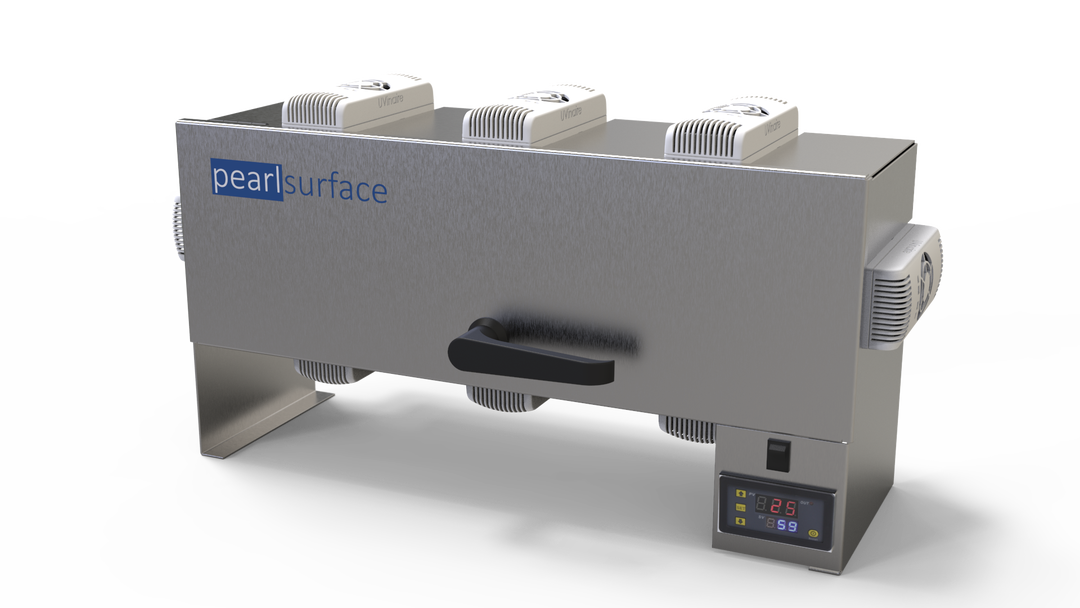

The PearlSurface 24G8 can disinfect three N95 masks at a time. A company in Erlanger launched the product after its CEO contracted COVID-19.

Provided | Aquisense

Protective masks have become increasingly hard to obtain as more Americans are diagnosed with COVID-19. The Centers for Disease Control and Prevention now recommends that people wear cloth masks, many of which are homemade, when they leave their homes.

Healthcare workers need more heavy-duty masks, such as the N95 masks.

A survey conducted by the U.S. Department of Health and Human Services Office of Inspector General found the most common equipment shortages in hospitals were N95 respirator masks, among other personal protective equipment. The shortages were so severe that some hospitals were experimenting with non-medical-grade gear such as construction respirators, cloth masks and handmade gowns, according to USA Today.

Kentucky officials are also asking people to donate N95 masks to healthcare workers.

Jeremiah Bruening works on the PearlAqua Micros at the welding station at AquiSense Technologies on Tuesday, April 7, 2020 in Erlanger, Kentucky. This is the smallest UV disinfection system in the world.

Meg Vogel/ The Enquirer

The light disinfection boxes from AquiSense Technologies can clean the masks for reuse. The boxes cost between $3,000 to $5,000. Each box can clean three N95 masks at once with UVLED lights. Lawal said it takes about 15 minutes to clean the masks and added that his company is working with several universities to confirm that's the right amount of time.

He got the parts for the box from India, Ohio and other areas. Everything gets assembled at his factory in Erlanger on Olympic Boulevard.

His company sold the boxes to the Kansas-based distributor Black and Veatch, which sells products to hospitals and healthcare facilities. He expects local hospitals to reach out directly to his company about purchasing them as well.

Daniel Craig works on the electronic assembly for the PearlAqua Micros at AquiSense Technologies on Tuesday, April 7, 2020 in Erlanger, Kentucky.

Meg Vogel/ The Enquirer

Lawal watched UVLED technology expand over the last 30 years.

Lawal is recovering but he doesn’t feel like he has full lung capacity yet, he said. Still, every day he works with his team to oversee the production and distribution of the machines that could save healthcare workers' lives.

“I would love for locals to contact us,” Lawal said.

Aquisense Technologies can be emailed at info@aquisense.com and called at 859-869-4700.

Taxonomy

- UV Disinfection

- Covid-19