Fashion for Good and SeaChange present ground-breaking solution to wastewater treatment

Published on by Water Network Research, Official research team of The Water Network in Technology

Wastewater treatment has always posed a significant challenge to manufacturers and fashion brands. Some, like the global sustainability initiative Fashion for Good, see it as an attractive opportunity for innovation. Together with its Scaling Programme start-up SeaChange Technologies, which has developed a game-changing wastewater treatment system, Fashion for Good has initiated a pilot project to assess the feasibility of the solution at scale. Corporate partners Arvind Limited, Bestseller, C&A and PVH Corp. participated in the pilot and will support future implementation of the technology in the supply chain.

“Fashion for Good is committed to finding and supporting the most disruptive technologies, such as SeaChange Technologies, to solve key issues in the fashion value chain. SeaChange has made substantial progress in just over two years as a Scaling Programme participant, culminating in this pilot, which provides them the momentum needed to further scale their technology,” commented Fashion for Good’s managing director Katrin Ley in a press release published on Thursday.

Arvind, Bestseller, C&A and PVH Corp. support Fashion for Good and SeaChange pilot

Arvind Limited, a global leader in apparel manufacturing focusing on textiles, advanced materials, and environmental solutions, provided access to the company’s effluent treatment plant in Gujarat, India, one the world’s largest textile manufacturing operations, to conduct a field evaluation. The SeaChange system was implemented over a period of three months to test and evaluate the feasibility of its widescale implementation.

“The Fashion for Good Scaling Programme gave us the opportunity to show the potential of our technology in the field by working with leading apparel brands,” said Dipak Mahato, founder of SeaChange Technologies.

Given that a conventional wastewater treatment process is very complex, SeaChange's technology is able to plug into several existing points of the conventional system. The pilot provided an opportunity to test SeaChange's technology in multiple different waste streams such as sludge, dyeing concentrates and combined effluent, Reverse Osmosis reject and “Mother Liquor”, the liquid concentrate that is left after crystallisation or other similar water treatment processes.

According to Fashion for Good, all waste streams were successfully treated by the SeaChange system and reduced to minerals in a single pass, demonstrating the technical viability of the technology to process wastewater. Sludge was selected as the most viable application for SeaChange, given its hefty environmental impact and cost of disposal.

How does the wastewater treatment process work?

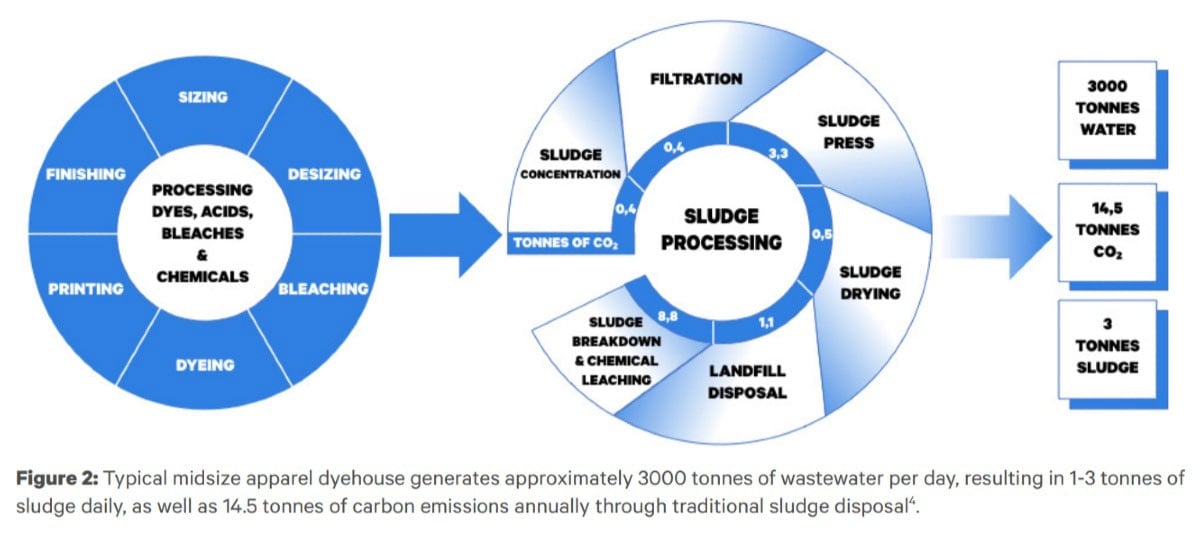

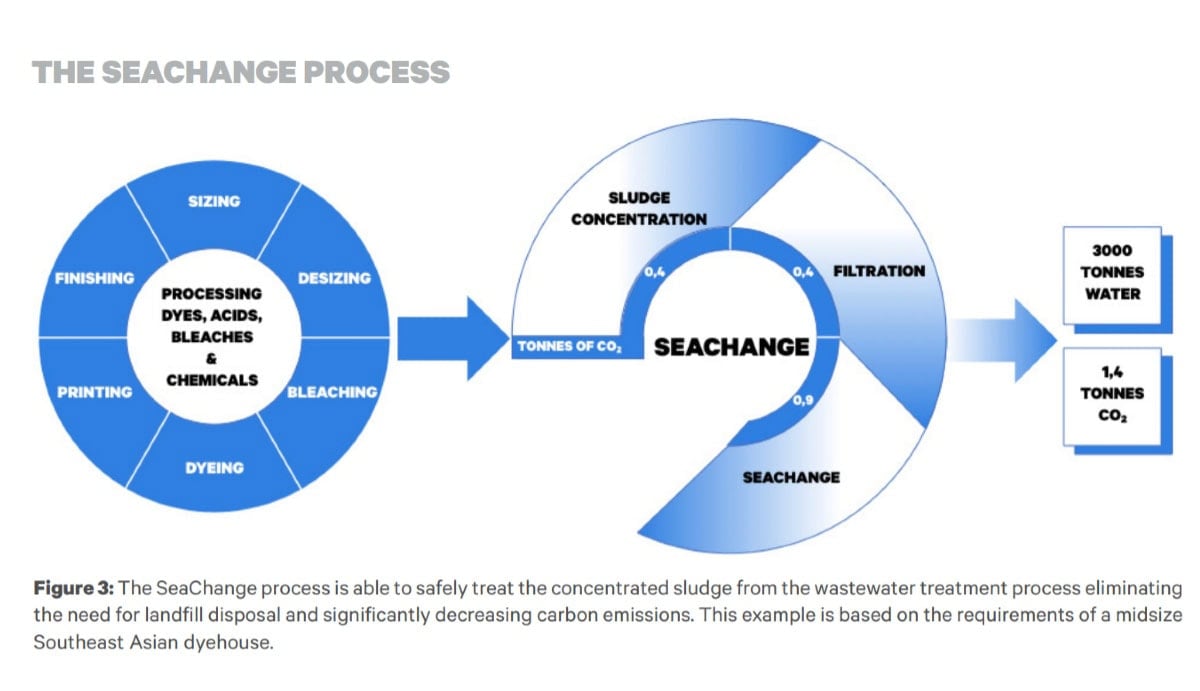

Specifically, SeaChange Technologies has developed an innovative mechanical system where wastewater or sludge is heated, pressurised and injected as an aerosol into a cyclonic separator. “This single-step process uses the cyclonic separation technique to draw out unwanted materials, microplastics and other non-biodegradable components from the water itself. Due to the heat and presence of oxygen in the air, these organic compounds then undergo thermal oxidisation causing them to degrade to CO2,” explains the company.

Through near-critical water conditions, where about 5-10 percent of the water mass becomes ionised, free radicals are created that can destroy most organic material. “By using heat from the organic oxidation process, energy use in maintaining this near-critical environment is incredibly efficient, using only about 60 percent of what would otherwise be required for water vapourisation,” it adds. The process enables the treatment of wastewater while eliminating the production of sludge and mitigating greenhouse gas emissions; the CO2 generated is just a small fraction of the greenhouse gasses generated by conventional processes.

In view of a typical dyehouse generating 1 to 3 tonnes of sludge per day from wastewater treatment, costs are tremendous considering that sludge disposal costs over 200,000 US dollars annually. The said amount also generates over 5,000 tonnes of greenhouse gases per year. “Implementing the SeaChange system into their treatment facility will effectively eliminate such costs as well as the associated environmental impacts,” explains SeaChange.

“Effective wastewater treatment remains a big challenge for the textile and apparel industry, finding an efficient solution is crucial for the industry. C&A is committed to achieve zero discharge of hazardous chemicals throughout the supply chain and supporting its suppliers in their continuous improvements to achieve it,” confirms Aleix Busquets Gonzalez, head of global sustainability at C&A.

In the coming year, SeaChange will be pursuing funding and strategic partnerships in order to implement the commercial application of their system on a wide scale.

Taxonomy

- Industrial Water Treatment

- Wastewater Treatment

- Industrial Water Treatment

- Textile

- Wastewater Treatment Chemicals and Consulting