Flexible compact flotation unit improves water treatment efficiency

Published on by Water Network Research, Official research team of The Water Network in Business

Produced water is becoming more of an issue for oil producers, both in terms of increased water cuts in mature fields and the more stringent environmental requirements being implemented.

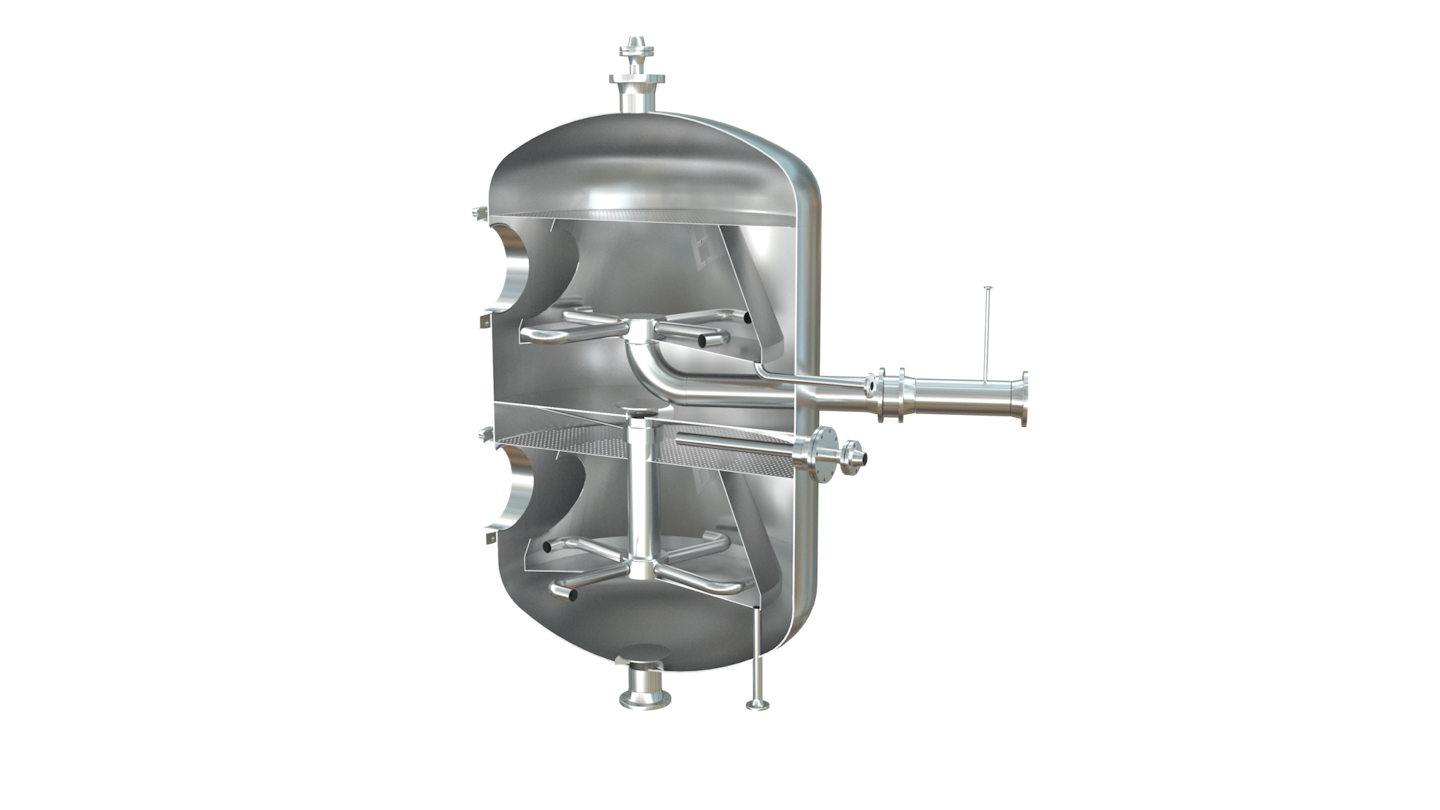

The Stauper CFU removes oil, gas and solids from the produced water, has no moving parts, and requires no external power and minimal maintenance.

(Courtesy Stauper Offshore)

Roland Ofstad and Rune G. Nilssen , Stauper Offshore AS

Produced water is becoming more of an issue for oil producers, both in terms of increased water cuts in mature fields and the more stringent environmental requirements being implemented. It is estimated that 250 Bbbl of water are “produced” every day worldwide, and this water must be cleaned down to microscopic levels before being discharged or reinjected into the reservoir to maintain pressure. The last step in produced water treatment is often to use a compact flotation unit (CFU) to ensure the oil-in-water (OiW) level is reduced to national requirements, less than 30 ppm or often far below.

The first CFU was developed and patented in Norway 20 years ago in order to accommodate space and weight constraints at offshore production platforms. Today, the CFU is a well-established flotation technology in use all over the world. Joern Folkvang, one of the founders of Stauper Offshore was also the co-inventor of the first CFU in 1999. He has since authored several patents for CFU related technologies, most recently the patented Stauper CFU.

Earlier design principles

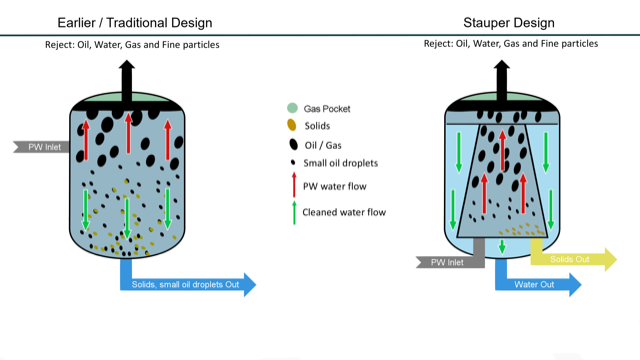

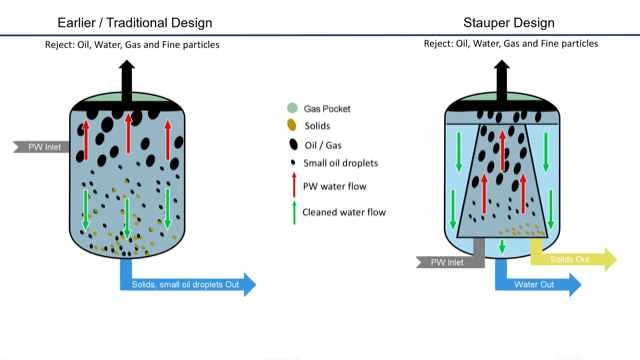

CFU is a vertical separation vessel that uses gas flotation principle. In other words, the main vehicle for separation of the oil from water is gas, either dissolved in or added to the produced water. Gas aids in the agglomeration and coalesce of the oil droplets. The expanding bubbles will rise the oil to the top of the vessel where it is removed.

In the earlier generations of CFU technology, this process happens in an open vessel where water is often introduced at the upper part of the vessel, and coalescence, flotation, and separation are all done in the open setting. These earlier designs carry many challenges, including counter-current flow, where smaller oil droplets and solids tend to follow the gravity and stream of treated water, thereby impeding efficiency.

Further on, the energy in the open vessel, with continuous moving water is less than ideal for removing oil from water.

Main features of the Stauper CFU

Stauper has solved the challenges in earlier designs by developing a new set of internals: a separate inlet chamber with a unique water flow and control. Water is introduced at the bottom of the vessel, into the inlet chamber where several non-moving tangentially distribution pipes create a stronger coalescence and oil droplet expansion. The inlet chamber traps small oil droplets forcing them up rather than out with the water. Solids are captured and flushed out at the bottom.

The patented Stauper CFU also has unique features that make the water flow come to a complete stand-still at the top of the tank, which again makes for an easy reject of oil and gas. At the bottom there is also reject of solids, which can be operated automatically or manually. This helps against clogging and reduces the need for maintenance. The clean water flows down on the outside of the inner chamber and is then discharged.

For many oil producers operating in cramped facilities, space limitations might call for designs that have two or more cleaning stages in one CFU vessel. Therefore, the company has also developed a design that will reduce both footprint and weight.

Retrofit

The CFU can have multiple stages in one vessel.(Courtesy Stauper Offshore)

The CFU can have multiple stages in one vessel.(Courtesy Stauper Offshore)

The fundamental idea behind the Stauper CFU is the water flow control by the inlet chamber. This inlet chamber can also easily be installed and retrofitted into existing oil and water separation vessels. For instance, degassers, open-vessel design CFUs, and water oil separators. The economic and environmental benefits are significant compared to investing in new process equipment. Earlier this year, a major operator awarded the company a contract to retrofit two, existing open-vessel design CFUs. Another operator has commissioned the company to determine if its ch allenged open design CFUs can be retrofitted.

allenged open design CFUs can be retrofitted.

Taxonomy

- Produced Water Treatment

- Steam Assisted Gravity Drainage (SAGD) Produced Water