Making desalination attractive

Published on by Water Network Research, Official research team of The Water Network in Technology

This month’s TechOffers features three innovative solutions that address challenges faced in water treatment, helping to ensure enough clean water for generations to come.

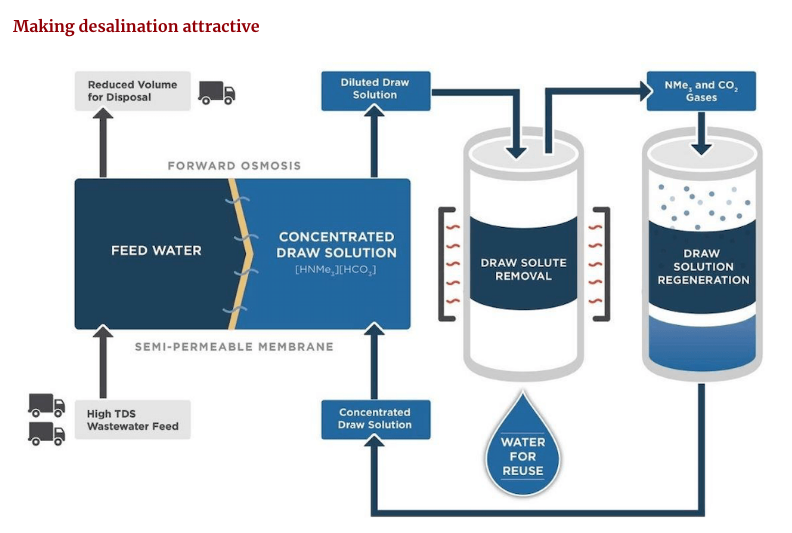

Making desalination attractive

Solutions that can treat wastewater cheaply and efficiently are therefore highly sought after. A report from Meticulous Research predicts that the water and wastewater treatment market will be worth US$211.3 billion by 2025.

One promising approach to wastewater treatment is the use of forward osmosis technology; where a concentrated salt solution is used to draw clean water from contaminated sources across a semi-permeable membrane. Although it is energy efficient, forward osmosis requires the concurrent separation of the draw salt to produce clean water. To overcome this challenge, a company has developed a proprietary switchable salt mixture that can be removed through moderate heating, leaving behind clean water as the final product. The evaporated gas can be recovered and recycled as fresh draw salt in a continuous closed loop process. The technology could extract up to 80% of the original waste volume as clean water, and could potentially be applied for desalination, oil and gas production.

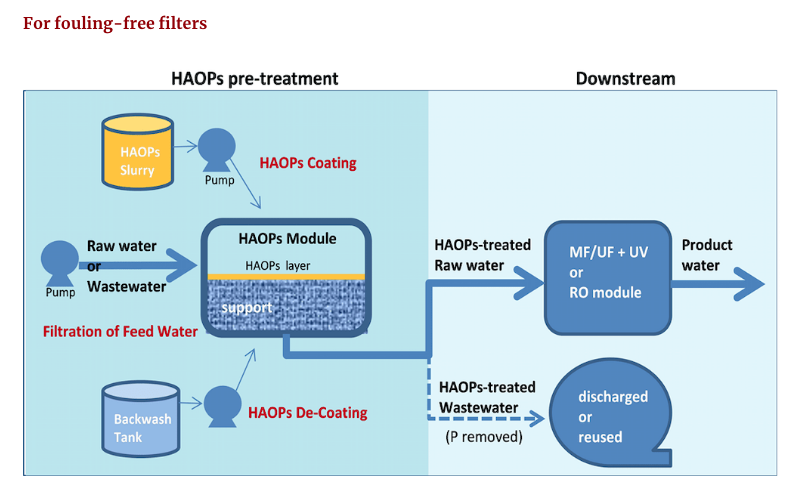

For fouling-free filters Many wastewater treatments apart from forward osmosis involve some form of membrane filtration. Unfortunately, the nature of filtration is such that contaminants deposit onto the membrane surface over time, blocking its pores and reducing its efficiency.

This phenomenon is known as membrane fouling. To tackle the problem of fouling, a company developed a pre-treatment technology for water using heated aluminium oxide particles (HAOPs). They found that HAOPs were effective in removing organic matter from water, significantly mitigating membrane fouling in subsequent filtration steps, prolonging the membrane’s lifespan. The technology is also an efficient and cost-effective way of removing phosphorus, reducing its levels by 99.9% after treatment. Moreover, sludge generated from the pre-treatment was far easier to dewater, dry and dispose of compared to conventional methods, saving costs for transport and disposal in the process. Separating what cannot be mixed Separating liquids from each other is a widely used industrial process that is currently inefficient and energy consuming. In particular, separating complex liquid mixtures such as wastewater from chemical engineering or food-based industries is highly challenging.

SOURCE Asian Scientist Magazine

Media

Taxonomy

- Sea Water Desalinisation