Nanostructured Wood Membrane for Efficient and Renewable Water Purification

Published on by Water Network Research, Official research team of The Water Network in Technology

A membrane made of a sliver of wood could be the answer to renewably sourced water cleaning. Most membranes that are currently used to distill fresh water from salty are made of polymers based on fossil fuels.

Inspired by the intricate system of water circulating in a tree , a research team from the University of Maryland, Princeton University , and the University of Colorado Boulder have figured out how to use a thin slice of wood as a membrane through which water vapor can evaporate, leaving behind salt or other contaminants.

A new treatment for wood could make renewable salt-separating membranes. (Image Source: MTech)

“This work demonstrates another exciting energy/water application of nanostructured wood, as a high-performance membrane material,” said Liangbing Hu , a professor of materials science and engineering at UMD's A. James Clark School of Engineering, who co-led the study.

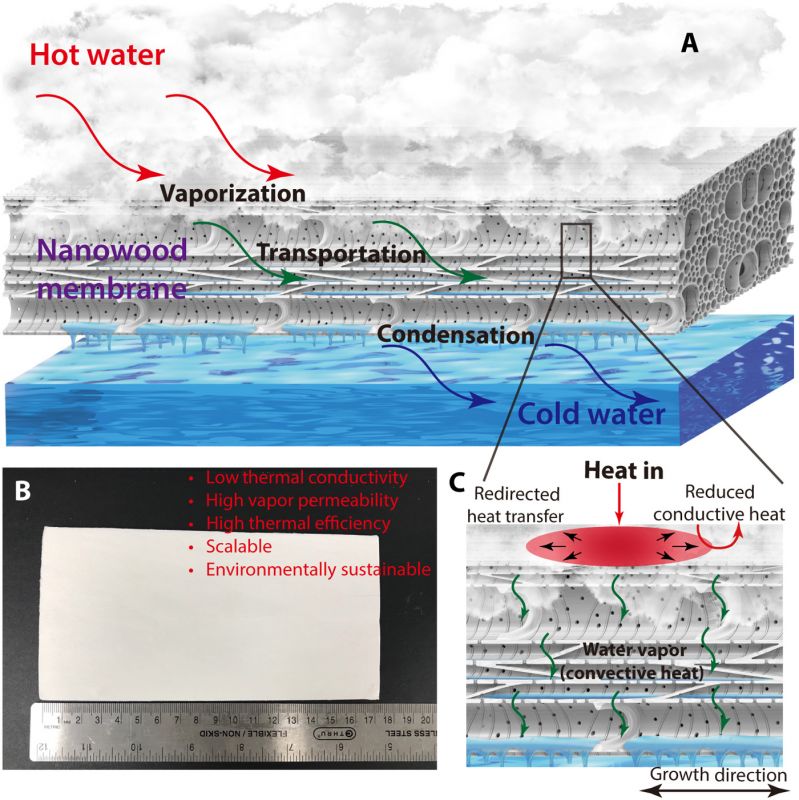

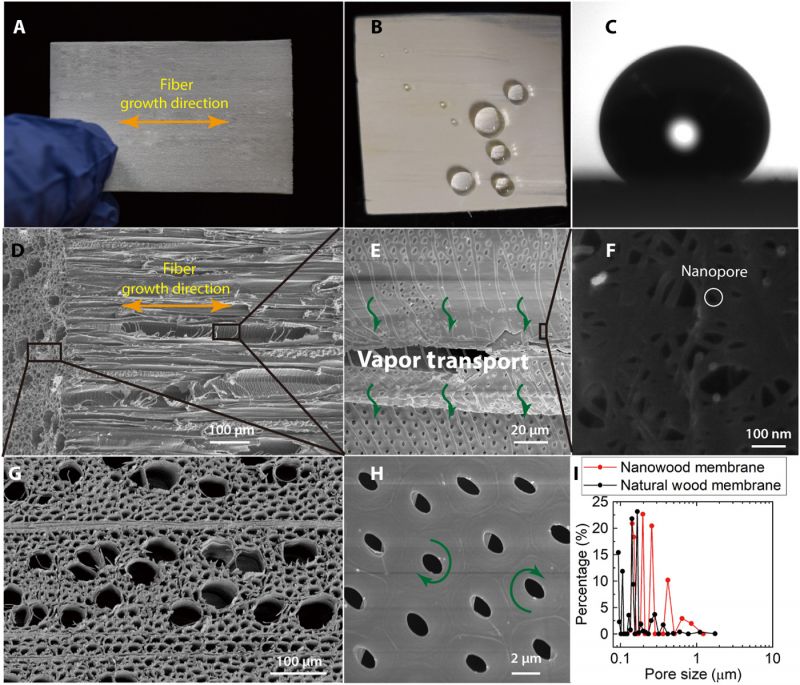

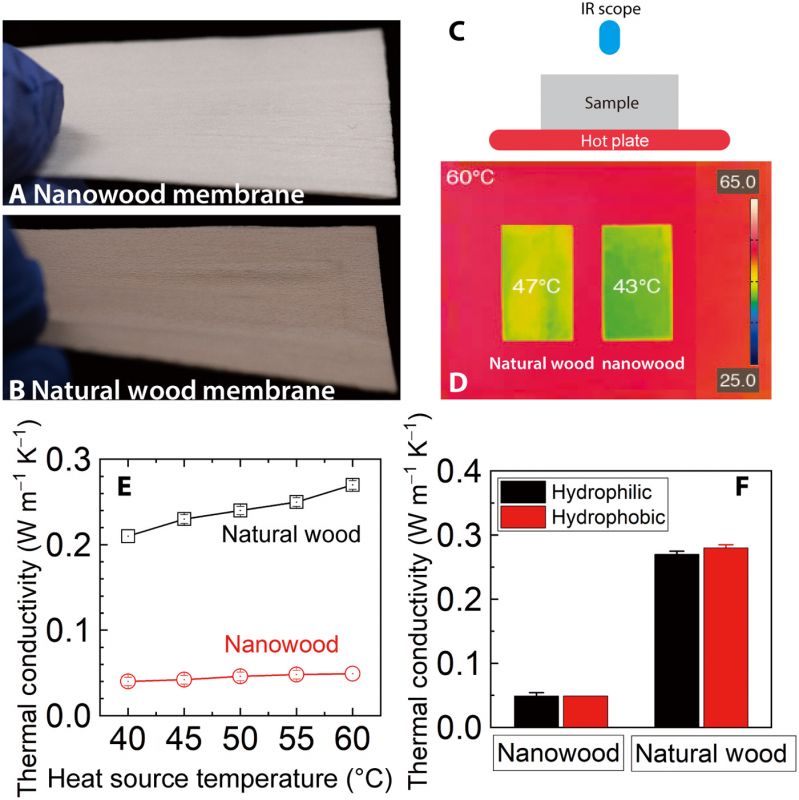

The team chemically treated the wood to become hydrophobic, so that it more efficiently allows water vapor through, driven by a heat source like solar energy.

“This study discovered a new way of using wood materials’ unique properties as both an excellent insulator and water vapor transporter,” said Z. Jason Ren, a professor in environmental engineering who recently moved from CU Boulder to Princeton, and the other co-leader of the team that performed the study.

The researchers treat the wood so that it loses its lignin, the part of the wood that makes it brown and rigid, and its hemicellulose, which weaves in and out between cellulose to hold it in place. The resulting “nanowood” is treated with silane, a compound used to make silicon for computer chips. The semiconducting nature of the compound maintains the wood’s natural nanostructures of cellulose, and clings less to water vapor molecules as they pass through. Silane is also used in solar cell manufacturing.

(A) Schematic of MD using the wood membrane. (B) Digital photograph of the nanowood and the corresponding beneficial properties for MD applications. (C) Schematic of the water (vapor) and heat transfer in the wood membrane during MD. (Photo credit: T. Li, University of Maryland; Photo Source: Science Advances)

The membrane looks like a thin piece of wood, seemingly bleached white, that is suspended above a source of water vapor. As the water heats and passes into the gas phase, the molecules are small enough to fit through the tiny channels lining the walls of the leftover cell structure. Water collected on the other side is now free of large contaminants like salt.

To test it, the researchers distilled water through it and found that it performed 1.2 times better than a conventional membrane.

“The wood membrane has very high porosity, which promotes water vapor transport and prevents heat loss,” said first author Dianxun Hou, who was a student at CU Boulder.

A) Photo of the hydrophobic nanowood membrane. (B) Photo that shows hydrophobicity after silane treatment. (C) Water contact angle of the nanowood membrane. (D) SEM images of the nanowood surface that exhibit aligned texture, xylem vessels, and lumina (channels). (E) SEM images that exhibit mesopores [(G) cross section and (H) pits] growing on the walls of the xylem vessels and lumina. (F) SEM images that exhibit microsized pores amid the cellulose fibers. (I) PSD of the hydrophobic natural wood and nanowood membranes. (Photo credit: D. Hou, University of Colorado; Photo Source: Science Advances)

(A) Photo of the hydrophobic nanowood membrane. (B) Photo of the hydrophobic natural wood membrane. (C) Schematic representation of contact heat source measurement. IR thermographs of (D) the wood membranes. (E) Measured thermal conductivity of the wood membranes from 40° to 60°C. (F) Comparison of the thermal conductivity of the woods at 60°C before and after hydrophobic silane treatment. Error bars represent the SDs based on three independent experiments. (Photo credit: D. Hou, University of Colorado; Photo Source: Science Advances)

Inventwood, a UMD spinoff company of Hu’s research group, is working on commercializing wood based nanotechnologies.

Reference:

Dianxun Hou, Tian Li, Xi Chen, Shuaiming He, Jiaqi Dai, Sohrab A. Mofid, Deyin Hou, Arpita Iddya, David Jassby, Ronggui Yang, Liangbing Hu, Zhiyong Jason Ren, "Hydrophobic nanostructured wood membrane for thermally efficient distillation", Science Advances, August 2019, DOI: 10.1126/sciadv.aaw3203

Media

Taxonomy

- Treatment

- Water Distillation

- Purification

- Technology

- Nanotechnology

- Desalination

- Multi-Stage Flash Distillation

- Multi-Effect Distillation

- Low Temperature Distillation

- Wood

- Water

- Water Purification

- Renewable Water Resources

- Desalination

- Nanotechnology

- Materials

- Nanofiltration

- Water filtration, purifiers, nano filtration

- Membrane distillation