Optimized Water Softening Systems Thanks to Quality-controlled Regeneration

Published on by Christina Schellbach, manager marketing and sales at OFS GmbH in Technology

Novel water hardness monitoring

For the production of soft water, ion exchangers with sodium chloride regeneration have been used for more than 50 years. The course and dynamics of the softening process depend on the ion exchange resins used, the regeneration processes, the removal quantities and their dynamics.

In practice, these processes do not operate consistently, so the resin capacities are not exhausted in all water softening systems for reasons of variability and the lack of process monitoring, indeed, investigations have revealed reserves of 20% to 50% of resin.

Constantly monitoring the softening process, is desirable to control the water softening system more accurately and appropriately. However, this is not possible with today's largely traditional photometric measuring techniques.

Limits of conventional processes

In recent decades, the cyclic photometric measurement method has emerged as the technical standard for soft water monitoring. The residual hardness is determined randomly by means of colour change, the residual water hardness value determined is compared with the specified soft water threshold value and the alarm is triggered when the threshold value is exceeded.

With a larger number of measurements, the indicator consumption and the mechanical wear of the measuring device increase, resulting in readjustment, cleaning and functional control with increased service costs. To avoid this, long measurement breaks with low indicator consumption and low measurement frequency are sought.

Regardless of this, however, ageing processes occur, which lead to creeping problems that would not occur with increased measurement frequency. In addition, manual control activities must be performed to verify the process safety and to compensate for the lack of accuracy.

Thus, a compromise between measurement frequency and susceptibility has to be found in order to limit operating and maintenance costs. However, a high level of process reliability and continuity is increasingly being sought.

Process-safe continuous soft water monitoring

By means of a novel soft water monitoring process, which was developed with the product line "Softcontrol" of the OFS GmbH, a measuring and control device with potentiometric measuring capabilities for the permanent monitoring of soft water is now available. This monitors the residual hardness and the measurement functionality very sensitively and cyclically and also incorporates intelligent self-monitoring.

Previous problems and obstacles associated with conventional measuring techniques are solved and a highly reliable, economically viable and continuous measuring functionality is ensured over long periods.

The process principle is based on a calcium-magnesium-selective electrode, which constantly monitors the variability in water hardness and evaluates this to a predetermined threshold value.

A method which offers the possibility of excluding sensor drift and the need to monitor the sensor quality, enabling water hardness to be monitored in a controlled, secure and robust process. A process which also allows for the quality-controlled regeneration of water softening systems. Thus, a premature release of water softeners is prevented and the existing soft water is utilised optimally.

Effective capacity utilisation

For the first time, this equipment, with a sensor life independent of the measuring cycles, enables continuous monitoring of water softening systems under economically effective conditions.

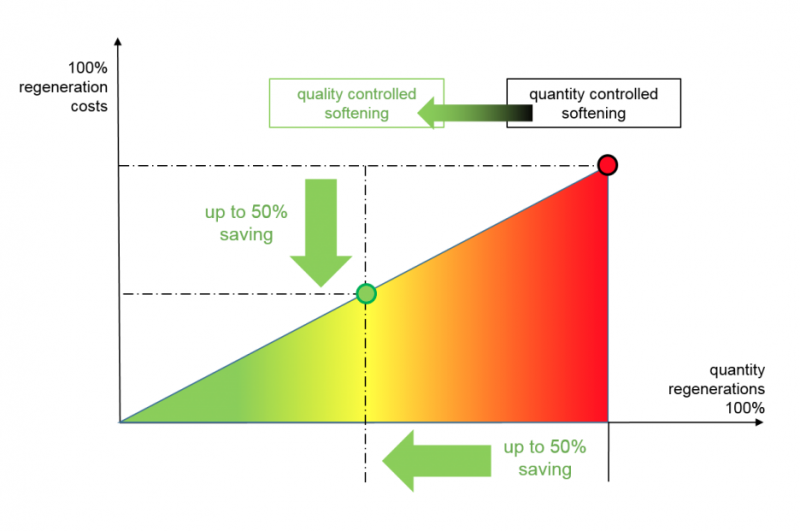

Thus, according to different practical conditions, 20% to 50% fewer regeneration cycles could be achieved when switching from batch to the quality-controlled operation of the water softener. This reduces the costs of regeneration, keeping the amount of soft water constant and the quality of the water high.

Conclusion

The new measurement process provides an economically viable and process-safe alternative to manually monitoring the softening process. Ensuring the full utilisation of the softening plants so that resources are saved, the amount of rinse and salt water used is significantly reduced and the amount of soft water increases. The device range leads to high process reliability and at the same time an ecological operation.

Media

Taxonomy

- Automation

- Monitors

- Sensor Systems

- Optimization

- Industrial Water Managment

- Process Instrumentation