PUB Opens World’s Largest Ceramic Membrane Water Treatment Plant (Video)

Published on by WWTP Designs Research, Contributing Editors in Technology

A decade of R&D efforts in ceramic membrane technology to enhance water treatment capabilities at Choa Chu Kang Waterworks.

National water agency PUB is proud to unveil its latest state-of-the art water treatment plant at Choa Chu Kang Waterworks (CCKWW) , that houses the largest ceramic membrane system in the world* . This is the result of PUB’s long-term investments in R&D with over a decade of dedicated research and trials in ceramic membrane technology. Minister for the Environment and Water Resources, Mr Masagos Zulkifli, joined by about 100 guests, officiated the opening of the new facility this morning.

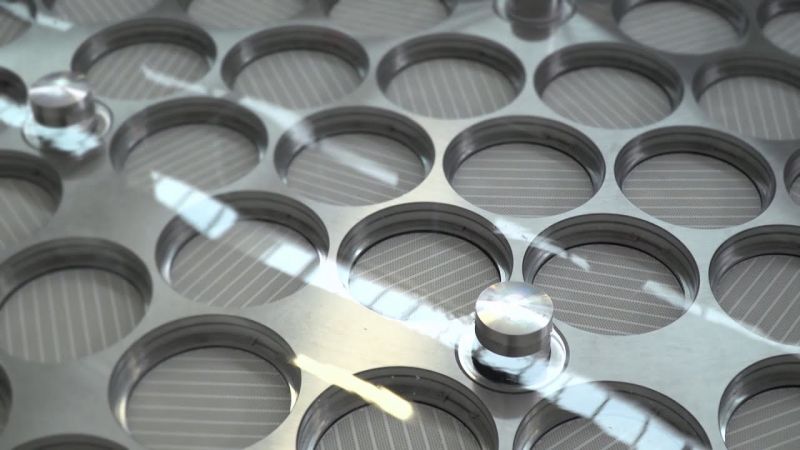

Ceramic membranes (YouTube screenshot)

Singapore’s most advanced water treatment facility

In addition to the large scale deployment of ceramic filtration membranes in CCKWW, ozone-biological activated carbon filters were also added to strengthen the disinfection and treatment process. PUB’s continuous R&D and innovation efforts to improve the efficiency of its water treatment process and operations ensures that we continue to produce safe drinking water for Singapore.

Ceramic membrane technology is one of the latest breakthroughs in membrane technology. It is more energy-efficient with a smaller land footprint, and cost-efficient with a longer lifespan. They are highly durable and expected to last 20 years; while polymeric membranes have to be replaced around every five years. More importantly, water loss is reduced significantly from 5% to 1% using ceramic membranes.

Continuous investments to enhance water treatment capabilities

One of Singapore’s oldest water treatment plants, CCKWW was built in two phases in 1975 and 1981, with a total capacity of up to 80mgd (million gallons per day), equivalent to about 145 Olympic swimming pools. CCKWW is Singapore’s second largest waterworks and treats water from the Western Catchment reservoirs – namely Kranji Reservoir, Pandan Reservoir and Tengeh Reservoir.

Back in the 1970s, Singapore relied on conventional sand filtration systems to process water, remove turbidity, bacteria and large suspended solids from water. Subsequent advancements in technology increased the affordability of membrane technology. In 2008, CCKWW completed the first upgrade to replace sand filters with polymeric membranes, while PUB worked with industry partners to conduct trials on ceramic membrane technology.

Ceramic Membrane Treatment (Illustration by PUB)

The first ceramic membrane demonstration plant was built at CCKWW in 2011 after the initial pilot project at Bedok NEWater Factory showed encouraging results. Built at a cost of S$5million with a daily capacity of 1.2 million litres, the rigorous 18-month trial validated the efficiency and reliability of ceramic membrane use in water treatment.

The second upgrade of CCKWW commenced in 2016 to deploy ceramic membranes on a larger scale. This saw the construction of a new facility, installation of ceramic membranes and the inclusion of ozone-BAC treatment for the plant. Construction works took about three years at a cost of S$162 million.

“This reconstructed CCKWW, with its ceramic membrane technology, allows PUB to do advanced treatment of the tap water that we supply to homes, commerce and industry. That we are able to deploy this new technology on such a large scale is the result of years of research, experimentation and rigorous testing. Advanced treatment technologies will allow us to cope with the impact of an increasingly urbanised catchment and the negative effects of climate change on Singapore’s raw water quality”, said Mr Ng Joo Hee, Chief Executive, PUB.

PUB will progressively incorporate advanced water treatment processes in the other five water treatment plants in Singapor** when they are due for upgrade. Chestnut Avenue Waterworks and Woodleigh Waterworks are currently undergoing upgrading to include ozone-BAC treatment in the water treatment process, which are expected to be completed by end 2019.

Ozone Treatment (Illustration by PUB)

Training and upskilling workers to adapt to new technologies

As PUB adopts new technologies in plants to enhance operational capabilities, we have also been retraining and upskilling our employees so that they can adapt to the new work processes.

54 year-old Mohamed Salfarimi is one example. He joined PUB in 1986 as an Assistant Technician performing general plant operations duties such as conducting laboratory tests and operating the pumping systems. Over the years, Salfarimi kept up with continuous training to upgrade himself and learned new skills. PUB also sent him on a study trip to Germany to understand how ozone-BAC filtration systems operate, to prepare him to operate our more advanced water treatment systems and processes.

With a positive attitude and hard work, Salfarimi rose through the ranks to become an Operations Engineer today, supervising the shift teams and helping to implement enhancement projects to improve work processes at CCKWW. He was also part of the project team involved in upgrading the water treatment processes at the plant.

Biological Activated Carbon Filtration (Illustration by PUB)

Formation of Utilities Alliances to share knowledge and best practices

To keep abreast of water treatment technologies, PUB, PWN from Netherlands and South West Water (SWW) from the United Kingdom (UK) have come together to form a Utilities Alliance to share knowledge about the latest innovations, as well as share operational data and best practices on ceramic membrane systems for the next five years. A Memorandum of Understanding (MoU) was signed between the three utilities today.

All three utilities are currently deploying ceramic membrane systems in their water treatment plants. Other than Singapore’s CCKWW, the system is also used in PWN’s Andijk III plant in The Netherlands, and SWW’s Mayflower Plant in Plymouth, UK.

* CCKWW’s ceramic membrane system treats up to 40mgd (million gallons per day) of water.

** The five waterworks in Singapore are Bedok Avenue, Bukit Timah, Chestnut Avenue, Lower Seletar, and Woodleigh Waterworks.

Click or find attach below:

Infographic on the enhanced water treatment process at Choa Chu Kang Waterworks

Source: PUB Singapore's National Water Agency

Finally, watch the video on the upgrade:

Attached link

http://www.youtube.com/embed/986cLmcGinsMedia

Taxonomy

- Treatment

- Ultrafiltration

- Membrane Bioreactor Systems

- Filtration

- Technology

- Filtration Solutions

- Membrane Technology

- Wastewater Treatment Plant Design

- Ceramics