Part 5: 🌊 Troubleshooting High Sludge Blanket in Secondary Clarifier#### **A. High Secondary Clarifier Sludge Blanket****1. Diagnostic Tools ...

Published on by Hossein Ataei Far, Deputy Manager of the Research, Technology Development, and Industry Relations Center at NWWEC

#### **A. High Secondary Clarifier Sludge Blanket**

**1. Diagnostic Tools and Calculations 🔍**

- **Settleometer Test**: Assesses sludge settleability.

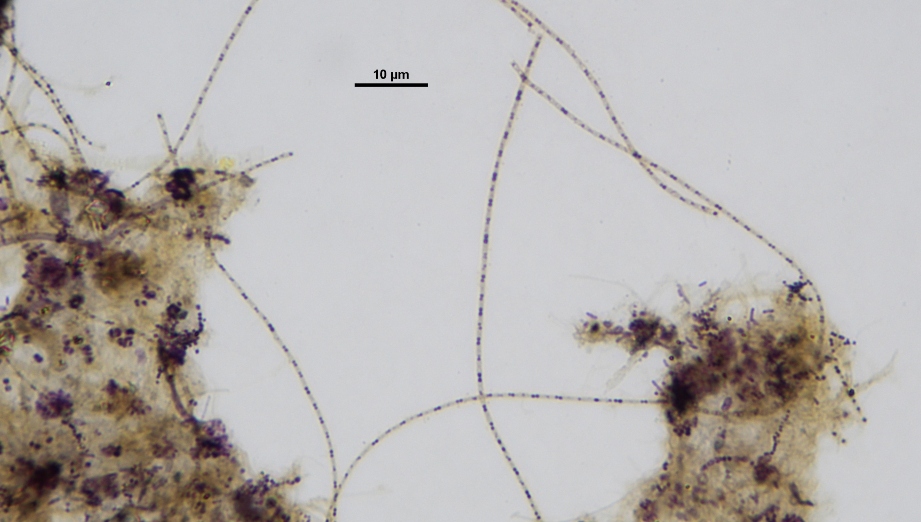

- **Microscopic Examination of MLSS**: Evaluates floc characteristics and presence of organisms or filaments.

- **Calculate SVI (Sludge Volume Index) and SDI (Sludge Density Index)**: Identifies issues related to compaction or biomass.

**2. High SVI, Low SDI**

**a. Filamentous Bulking 🦠**

- **Possible Causes:**

- **Low Dissolved Oxygen (DO)**: Ensure proper aeration 💨.

- **Low Organic Loading Rate**: Inadequate food for microorganisms 🍽️.

- **High Organic Loading Rate**: System overwhelmed by excess organic material 🌾.

- **Nutrient Deficiency**: Imbalance in C:N:P ratio 🧪.

- **Septic Wastes/Sulfides**: Address septic conditions 🦠.

**3. Normal SVI, SDI**

**a. Excessive Amount of Biomass 🌱**

- **Possible Actions:**

- **Recalculate CRT and Wasting Rate**: Adjust rates 📈.

- **Check Sludge Storage**: Ensure sufficient storage ❄️.

- **Address High SS and BOD in Supernatant**: Resolve sludge handling issues 🧪.

- **Prevent WAS Solids Carrying**: Ensure solids aren't bypassing primary clarifiers 🚫.

**b. Inadequate Return Sludge Rate 💧**

- **Possible Actions:**

- **Adjust RAS Pump Control**: Verify flow rates ⚙️.

- **Inspect Mechanical Components**: Check pumps, meters, and valves 🔧.

- **Clean Clarifier Sludge Sump**: Remove debris 🗑️.

- **Repair Sludge Collector**: Address mechanical issues 🛠️.

**c. Excessive Hydraulic or Solids Load on Clarifier 💦**

- **Possible Actions:**

- **Assess Surface Overflow Rate (SOR)**: Adjust operations if overloaded.

#### **B. Scum and Foam**

**1. White Billowing Foam ☁️**

- **Possible Causes:**

- **Plant Start-Up**: Foam due to low CRT, high F:M ratio, or organic overload 🏭.

- **Organic Overload or Shock Load**: Excessive or sudden organic loading.

- **Loss of Biomass**: Over-wasting causing foam 💧.

- **Recovering from Toxicity**: Foam during recovery 🧪.

**2. Dark, Scummy Brown Foam, Slurp 🛁**

- **Possible Causes:**

- **Extended Aeration**: Some foam normal in extended systems ⏳.

- **Excessive CRT**: High CRT contributing to foam 📈.

- **MLSS in Primary Effluent**: High levels causing foam 🧪.

- **Excessive Oil and Grease**: Leading to foam formation 🛢️.

The keynote by Deborah Lee, a microbiologist, discusses the significance of *Microthrix* filaments, specifically *Microthrix parvicella* and *Microthrix calida*, in wastewater treatment. Traditionally, *M. parvicella* is associated with foaming issues, but it can also cause sludge bulking, even without foam. This filament grows rapidly by extending outward from the floc, allowing it to access nutrients and store them as intracellular compounds. Despite its typical association with cold temperatures, *M. parvicella* can cause problems in warmer conditions, challenging the assumption that it's only a winter issue.

Taxonomically, *M. parvicella* is still referred to by its original name, although its classification is debated, and a similar filament (*M. calida*) has been discovered. The latter thrives in higher temperatures (>30°C), lacks the ability to cause foaming, and has a slightly thinner morphology. Both filaments contribute to bulking in wastewater treatment, although their effects differ.

In terms of morphology, both bacteria form long, thin, unbranched filaments, but *M. calida* can tolerate higher temperatures and does not cause foaming [2].

#### **Reference 📚**

[1] **State of Michigan Department of Environmental Quality** - *Activated Sludge Process Control*.

[2] https://teamaquafix.com/microthrix-bulking-in-summer/