Using Computer Frequencies to Improve Water Quality

Published on by Water Network Research, Official research team of The Water Network in Technology

Computer-generated frequencies are being used by Hydrosmart to alter the composition of water to improve quality and eliminate scaling.

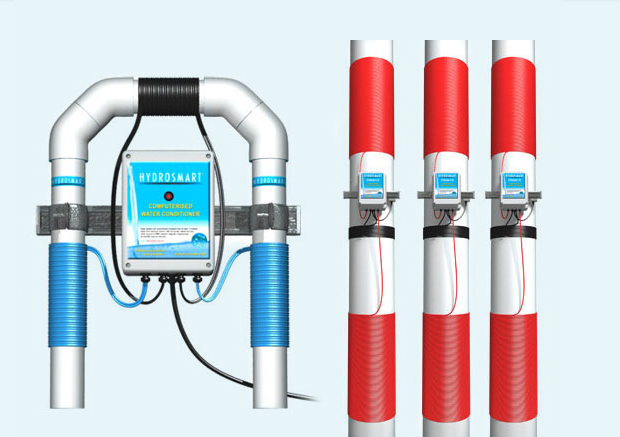

Hydrosmart has developed a device in Adelaide, South Australia that sits on the outside of pipes, treating water as it passes without the use of chemicals or filters.

Hydrosmart has developed a device in Adelaide, South Australia that sits on the outside of pipes, treating water as it passes without the use of chemicals or filters.

The microprocessor unit consists of an antenna wound in a metal coil, which emits a series of computer-generated frequencies to break down scaling in pipes, taps and containers.

The frequencies and pulses pass through the coil to charge the water externally.

This charge disrupts the bonds of minerals in the water, dissolving calcium, iron and gypsum scale off pipes. It also helps to reduce the size of the build-up when water passes through taps or shower heads.

Previously this had resulted in damaged hair and irritated skin.

Hydrosmart Managing Director Paul Pearce said all water infrastructure had minerals such as calcium or iron pass through, which could bond together and block pipes.

“We’re a water conditioning business that doesn’t use filters, chemicals or purifiers,” said Pearce.

“We are leading the way for non-chemical water treatment by charging the water externally to change the behaviour of the water, making it better and helping to make the infrastructure more sustainable in the long-term.”

Hydrosmart has taken its water treatment technology to the Pacific island-nation of Tonga where it is fitting a unit at the International Dateline Hotel.

“For many places, like Tonga, there are often limestone aquifers where the water is high in calcium and things like filters don’t dissolve salts – this affects soils, plants, pipes, plumbing and washing machines,” said Pearce.

“For many places, like Tonga, there are often limestone aquifers where the water is high in calcium and things like filters don’t dissolve salts – this affects soils, plants, pipes, plumbing and washing machines,” said Pearce.

For the Dateline Hotel, the addition of the unit means the laundry, kitchen and bathroom infrastructure is less likely to block up or produce hard water.

Pearce said the microprocessor unit was highly efficient and would only use about AU$10 per year worth of electricity in most cases, which is less than a standard light bulb.

“We can make salty water soft and useful for irrigation instead of it causing plant problems and scale. It’s a holistic shift using electronics and a computerised approach to water,” he said.

“Normally salts restrict the water intake but research has shown that by changing the charge it (salt) moves away from the roots of the plant and deeper through the soil profile, so plants can keep drinking even during hot days.

“The technology is ahead of the curve because people look at consumable technologies like reverse osmosis for squeezing salt out or water softeners for pulling the calcium out but you need a lot of power to achieve those outcomes.”

South Australia is the driest state in the driest continent in the world and has become a world leader in water treatment and reuse technologies.

Pearce said his device would work year-round as long as it remained plugged in and activated.

Water company Brita claims that 75 per cent of all catering equipment breakdowns are because of mineral scaling, according to U-Select Sales Manager Jon Steward.

Catering equipment distributor U-Select also claims about 60 per cent of the United Kingdom is exposed to more than 200 parts per million (ppm) of calcium or magnesium carbonates in its water supply.

According to the Australian Water Association, the level of scaling in the country’s capital cities ranges from 10ppm to 148ppm.

Hydrosmart has also taken its technology to other countries such as Bangladesh and aims to continue its global expansion.

Source: Pace Today

Media

Taxonomy

- Technology

- Filtration

- water treatment

- Microprocessors