AI Technology Controls Pressure and Reduces Loss by Leakage in Water Networks

Published on by Water Network Research, Official research team of The Water Network in Technology

A system developed by a FAPESP-supported startup -- and already in use in 35 companies -- has reduced water loss in distribution networks providing seven municipalities in Brazil.

Software already used by Coca-Cola Femsa to reduce liquid waste from the soft drink bottling process has cut water waste due to leakage by 2%, equivalent to 2.5 million cubic meters per year, in distribution to a region comprising seven municipalities in Rio de Janeiro State, Brazil, whose sanitation services are provided by private concessionaire Prolagos.

The system is called Leaf and was developed by I.Systems, a firm supported by PIPE, the Innovative Research in Small Business Program of the São Paulo Research Foundation - FAPESP. The technology developed by the startup controls several variables in a production line based on fuzzy logic (a branch of Artificial Intelligence, or AI) and is currently used by more than 35 companies.

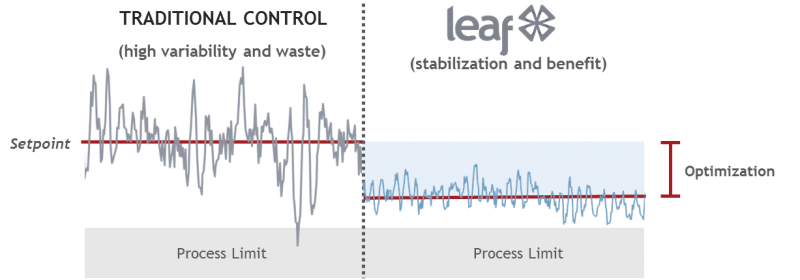

Example of Leaf implementation results in a industrial process, Source: ISystems

"Control of water pressure in a distribution network is considered one of the most important operational factors in water distribution," says Igor Santiago, president of I.Systems. "Low pressure may be insufficient to transport the water to the most distant or highest points in a city. High pressure increases leak losses and may lead to burst pipes."

According to Santiago, Leaf system's main advantage when paired with Brazilian sanitation industry standard technology has to do with its ability to monitor the entire distribution network in real time and in an integrated manner. Conventional technology in Brazil uses booster pumps to direct water flow via high pressure and pressure-reducing valves (PRVs) to stabilize pressure at certain points.

Prolagos, the private company responsible for providing public sanitation services for the municipalities of Araruama, Armação dos Búzios, Arraial do Cabo, Cabo Frio, Iguaba Grande, São Pedro da Aldeia and Saquarema, had been pursuing an integrated and automated solution to control boosters and PRVs in its distribution networks in order to reduce leak losses.

"The technology available until now basically looks at water pressure before the pump or valve and decides what the booster or PRV should do. The problem is that this may have an impact downstream, such as lack of water in taps or a pressure jump that could lead to a pipe burst," Santiago says.

72h-period water network automated operation

The solution developed by I.Systems uses AI to interconnect variables such as time and date (including whether it is a holiday), local temperature, time of year and whether it is vacation season, among others and adjusts water pressure accordingly in the distribution network.

The software uses all this information to adapt pressure instantly to changes in demand and can predict supply requirements for periods of up to 72 hours.

"Based on this dataset, the AI system makes a projection and assigns water pressure responsibilities to each booster and PRV in the network," Santiago says.

"It's as if all the pumps and valves in the network operated as a single intelligence, in a global and integrated manner, instead of individually. This means, for example, that it prevents activation of a valve causing unwanted effects elsewhere in the work. In sum, it optimizes the operation as a whole."

The system took a week to adapt to the region's water supply profile and then automatically optimized pressure control. The result was a 5.8% reduction in the average flow rate without jeopardizing supply.

More efficient control thanks to the software also resulted in a 15% reduction in the minimum nighttime flow rate and hence cut losses throughout the network.

Read full article: EurekAlert

Media

Taxonomy

- Leakage Detection

- Data Management

- Leakage

- Infrastructure

- Leakage Reduction

- Infrastructure Management

- Water Software

- Pipes and Pipelines