CO2 Dyeing, Biosynthetics Driving Transition Towards New Textiles Economy

Published on by Water Network Research, Official research team of The Water Network in Technology

A new textiles economy is on the horizon as innovative textile and chemical firms develop new chemical- and petroleum-free processes to produce fabrics and materials.

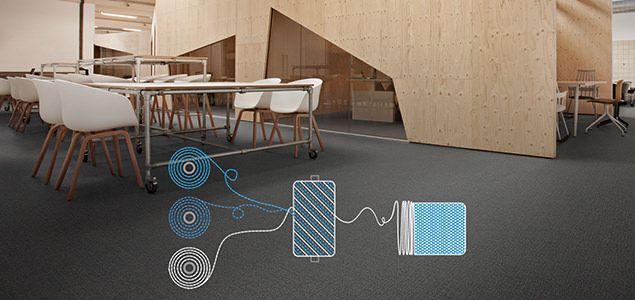

Photo source: Aquafil (Via Sustainable Brands)

Global textile chemicals company Archroma has begun using what the textile industry considers to be the world’s first water-free and process chemical-free dyeing solution with its optical brightening agent Ultraphor® KCB. The technology is based on carbon dioxide instead of water and was developed and patented by Dutch processing engineering company DyeCoo Textile Systems B.V.

When pressurized, CO2 becomes “supercritical,” a phase between a liquid and a gas. In this state CO2 has a very high solvent power, allowing dye to dissolve and be transported easily and deeply into fibers, creating bright whites and vibrant colors. The CO2 is reclaimed from existing industrial processes, recycling 95 percent of it in a closed-loop system. The technology uses 100 percent dyes with more than 98 percent uptake and uses no process chemicals and no water. As a result, no wastewater is produced.

...

Meanwhile, Italian textile firm Aquafil has agreed to a multi-year partnership with bioengineering company Genomatica to develop sustainable caprolactam, a key ingredient used in producing Aquaful’s signature 100 percent sustainable nylon.

The collaboration aims to develop a commercially-advantageous bioprocess (Genomatica’s GENO CPL™ process) to make the material using plant-based, renewable ingredients, rather than the crude oil-derived materials traditionally used by the nylon industry.

Petroleum-based caprolactam is used in a variety of applications, including carpets and apparel. The material has a global market of over five million tons a year. Genomatica’s GENO CPL process aims to provide a sustainable way of making caprolactam with better economics, including for smaller-scale plants. Additionally, it will enable licensees and their customers to differentiate themselves by offering a more sustainable bio-based product whose performance will be fully comparable with traditional nylon, and which will not require any machine or process adjustments in the existing nylon supply chain.

Read full article: Sustainable Brands

Media

Taxonomy

- Textile

- Wastewater Disposal

- Wastewater Phycoremediation

- Sustainable Development

- Sustainable Water Resource Management

- Chemicals

- Chemical Materials

- Fibers & Textiles

- Textile