Pipework Hygiene Begins With the Pipes Themselves

Published on by Maya Jones, employee at Thames Water in Government

The design and installation of pipe systems needs including within water-quality strategies, believes Des Dolan of Durapipe.

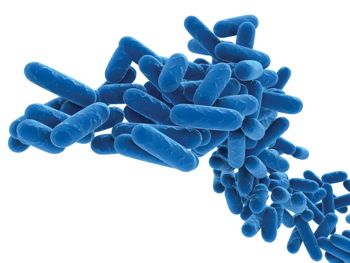

The issue of water quality has risen up the agenda in recent years, particularly within healthcare environments. Several major cases of Legionnaires’ Disease have hit the headlines across the globe, and legislation surrounding water systems and their operation has become more stringent.

Pipe networks are the biggest carrier of waterborne bacteria, such as legionella pneumophila, and facilities managers have become more proficient at ensuring systems are correctly monitored and maintained once operational. However, Durapipe is concerned that the design and installation of pipework systems is just as important and should always be considered within water strategies.

Pipe networks are the biggest carrier of waterborne bacteria, such as legionella pneumophila, and facilities managers have become more proficient at ensuring systems are correctly monitored and maintained once operational. However, Durapipe is concerned that the design and installation of pipework systems is just as important and should always be considered within water strategies.

A lot of positive steps have been taken, with many healthcare authorities now implementing dedicated water-safety groups, responsible for monitoring, treating and maintaining a building’s water supply. However, it is vital that suppliers and manufacturers are represented win these groups to ensure the most effective solutions can be delivered.

Revisions to ‘HTM 04-01: Safe water in healthcare premises’, made in May 2016, focus on hospital facilities formally establishing water-safety groups, with responsibility for developing water-safety plans for their buildings. The revisions also include new guidelines on the installation of water systems. ‘Part A: design, installation and commissioning’ clearly states that all materials used in a hot and cold water installation must comply with the requirements of the Water Supply (Water Fittings) Regulations 1999. Therefore, when selecting new pipework systems, the first step for any water-safety group is to ensure products possess the relevant approvals, which is where manufacturers can provide invaluable advice.

The document also provides detailed guidance on the different options of pipe material, covering the advantages and disadvantages of steel, copper and plastic pipes and warning that one pipe may not be suitable for multiple applications. The guidelines stress that ‘manufacturers’ recommendations should be strictly followed when selecting appropriate pipes and fittings for a particular application’.

The material choice for hot- and cold-water pipes cannot be underestimated. When considering treating bacterial growth in pipe networks, water-safety groups cannot purely focus on the maintenance and treatment of systems. While it is important that pipework systems are regularly maintained to ensure system safety, the initial design and material choice can help prevent bacterial growth from the outset.

Pipe networks are the biggest carrier of waterborne bacteria, such as legionella pneumophila

Bacteria settle and develop in biofilm, which easily attaches itself to sharp or jagged parts of a pipe’s surface, caused either by the quality of the extrusion of a new pipe or the corrosion/scale build up inside a used pipe. A rougher surface will provide a stronger platform for biofilm to grow; rough surfaces have more surface area for bacterial attachment and growth and also provide more shielding from flow.

The smoothness of the selected pipework is therefore an important factor to consider; while the surface of some metallic pipes is rough, the smooth bore of plastic pipes restricts the ability for bacteria to grow. While copper has natural anti-microbial properties, as limescale builds on the used, corroded pipe surface, the biofilms then cling to the limescale and begin to colonise.

By their very nature plastic pipework systems can help combat bacteria growth; the material characteristics offer corrosion and limescale resistant properties, resulting in a smooth bore, which can limit and slow the growth process. In addition to its performance capabilities.

Durapipe HTA, for example, also offers installation benefits. Its lightweight nature, combined with its quick and simple cold-weld jointing eliminates the need for hot works and skilled welders, further reducing the installation cost and time of projects.

The correct design and choice of pipework material is the first area that needs addressing when commissioning new hot and cold water networks. Once the pipes are installed, it is then vital to apply preventative measures on a continuous basis and undertake regular and thorough maintenance, sampling, cleaning and treatment. There are many effective methods that can be used to kill bacteria in pipework systems — including flushing through systems, thermal and chlorine treatments. Ensuring there is no water stagnation and allowing good water circulation throughout the system is an important ongoing check.

The only way to ensure a truly effective hot and cold water network is operational is to involve all parties from within the supply chain in water-safety groups — from manufacturers and suppliers through to facilities and maintenance managers. This approach will result in the most appropriate specification, design and installation being delivered — followed up with a robust strategy for monitoring, maintaining and treating water systems.

Written by Des Dolan, a brand manager for building services with Durapipe.

Source: MBS

Media

Taxonomy

- Infrastructure

- Utility Pipe Network

- Pipeline Installation & Maintenance

- Pipelines

- Pipes and Pipelines