Improve water sustainability with more accurate measurement

Published on by Trudi Schifter, CEO and Founder AquaSPE in Business

August 4th, 2021

Alan Hunt, Electromagnetic Flow Product Manager, UK & IE

Making water supplies more sustainable and maximizing revenues can help enable utilities to continue to bring water to more people. We look at how the growing capabilities of modern electromagnetic flowmeters can help minimize water losses and boost revenue.

Making water supplies more sustainable and maximizing revenues can help enable utilities to continue to bring water to more people. We look at how the growing capabilities of modern electromagnetic flowmeters can help minimize water losses and boost revenue.

Turning raw water full of potentially harmful bacteria into a clean, safe supply is no small feat. Every day, water treatment plants worldwide are busily turning millions of litres of untreated raw water into supplies that are safe for us to use. Operating 24 hours a day, seven days a week, these plants subject every drop drawn from a river, reservoir or borehole to a rigorous treatment process, involving multiple stages including coagulation, filtration and chemical dosing, to prepare it for distribution.

Once in the distribution system, these massive amounts of treated water are pumped through miles of pipeline, consuming massive amounts of energy to maintain the flows and pressures needed to meet our domestic, commercial, industrial and agricultural needs.

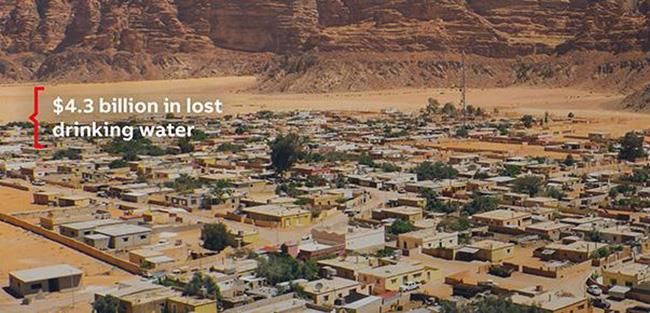

It’s therefore staggering to think that around 346 billion litres of this treated water are lost every day worldwide, representing a massive chance to recover lost water and revenues running into millions of dollars that could be re-invested into improving network performance.

While leakage is a major culprit behind the problem of lost water, it is not the only one. Inefficient measurement can also see millions of litres of water being incorrectly quantified, leading to confusion about exactly how much water is in a pipeline and where it is going.

Keeping track of lost water

When it comes to keeping track of lost water, there are two main approaches that can be taken.

The first is to make sure that measurements are taken in enough places to be able to get a full picture of what’s happening in the network and help plug any gaps in understanding how much water is being lost and why.

In remote areas, where it can be difficult to connect electronic flowmeters to a mains supply and retrieve data from those meters, developments in battery and renewable power and remote communications technologies are increasingly providing a solution.

The second approach concerns the choice of technology to measure flow. Depending on the application, different flow measurement techniques can be used, from constrictive methods such as flumes and weirs for open channel systems, to orifice, mechanical, ultrasonic or electromagnetic flowmeters in closed pipe systems. Many of these will have their own set of benefits and drawbacks that can affect their ability to measure accurately.

Effective measurement can reduce losses from distribution network

Electromagnetic flowmeter installation

For operators looking for consistent accuracy, high reliability and stability and suitability for a range of installation environments, electromagnetic flowmeters can present the answer. Compared to other flowmeter types, electromagnetic flowmeters offer greatly enhanced accuracy and repeatability throughout their operational life, with uncertainty of ±1 % reading or better. With no moving parts, they do not suffer from problems with wear and tear, minimizing maintenance and requiring no upstream strainers to filter sediment. A choice of flow primary linings offers added protection against high sediment flows, with users able to choose from a variety of materials, including ceramic linings for particularly abrasive flows.

The ability of electromagnetic flowmeters to better handle distorted velocity profiles also means that the amount of piping upstream and downstream of the meter is minimized, which can greatly reduce the time and cost of installation.

How ABB’s AquaMaster4 can help you get a deeper understanding of where your water is going

When it comes to achieving high accuracy measurement across the widest range of flows in any installation environment, ABB’s AquaMaster4 provides the answer. Its unique octagonal reduced-bore sensor bore design makes it virtually immune to flow profile distortions and enables it to deliver class leading accuracy to OIML Class 1 or ±0.2 % of reading ±0.5 mm/s (whichever is greater), across flow ranges of up to R1000.

For operators, this makes the AquaMaster4 the ideal tool for measuring water flows around the clock, even at night when demand is at its lowest.

With water companies needing to maximize the productivity of their engineering resources to help address the effects of skills shortages, the AquaMaster4 has also been designed to be simple and quick to commission, operate and maintain.

The inclusion of Near Field Communications (NFC) technology, for example, enables users to download configuration settings and retrieve logger data by tapping the transmitter with a smart device such as phone or tablet loaded with ABB’s Velox app. The AquaMaster4 can be fitted with an optional multi-speed, flowrate and pressure logger, which can be set to collect high resolution data at 15 second intervals. Using the Velox app, a variety of operational, logging and diagnostic data can be downloaded, interrogated and shared to provide precise details on flow and pressure activity over a set period.

Near Field Communications enable users to download configuration settings and retrieve data

Another feature is the inclusion of Sensus communications. Offered alongside Pulse and Modbus communications options, Sensus provides the ability to carry out Automatic Meter Reading (AMR). Allowing data to be collected remotely without having to gain physical access to the meter, Sensus is ideal for locations where there is no smart infrastructure available to relay it to a SCADA or other centralised control system.

Another feature is the inclusion of Sensus communications. Offered alongside Pulse and Modbus communications options, Sensus provides the ability to carry out Automatic Meter Reading (AMR). Allowing data to be collected remotely without having to gain physical access to the meter, Sensus is ideal for locations where there is no smart infrastructure available to relay it to a SCADA or other centralised control system.

This suitability for remote locations is further enhanced by a choice of power options. As well as mains and battery power, the AquaMaster4 can be connected to either a five-Watt solar panel or 60-Watt wind turbine generator to provide the energy it needs to function.

Media

Taxonomy

- Leakage Detection

- Leakage Reduction

- Strategic Asset Management

- Environmental Assessment & Management

- pipeline leak detection

- Leak Detection and Inspection