Mechanical Vapor Recompression Evaporator

Published on by Katharine Fan, project manager at Nomia machinery Co., Ltd in Technology

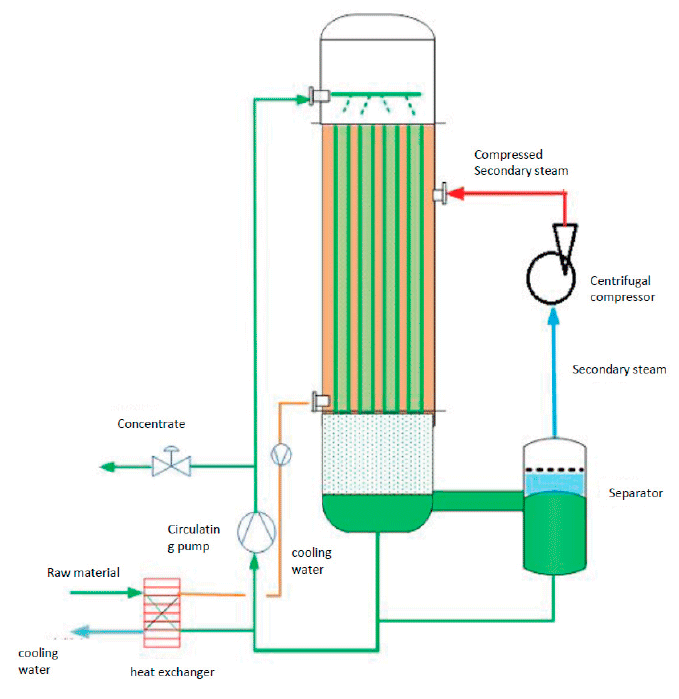

MVR is called Mechanical Vapor Re-compression. It uses the centrifugal compressor to re-compress the secondary vapor (low temperature and low pressure) which is evaporated from the liquid material to rise its temperature and pressure, so as to reuse it as heating source to evaporate the liquid material again.

The process is to convert a small amount of electric energy to more heat energy.

Theoretically, compared with single effect evaporator, MVR Evaporator can save more than 80% energy consumption and 90% cooling water.

Steam compressor is the key equipment for MVR Evaporator. There are different types of steam compressors for option, like centrifugal steam compressor, centrifugal blower, roots compressor etc. For different steam flow rate, different compression ratio and temperature rise, different compressor can show their advantages per special condition.

Media

Taxonomy

- Water Efficiency

- Technology

- Energy Efficiency

- Vapor Compression Distillation

- Evaporation