Vacuum Distillation System for Industrial Wastewater Treatment

Published on by Liv Dong, Director at Nomia machinery co., Ltd / wastewater treatment evaporator system in Business

A vacuum distillation system offers a number of advantages for the treatment of industrial wastewater.

In addition to drastically reducing operating and disposal costs, it also curbs bacterial growth significantly. If the wastewater is already contaminated, the treatment process can also serve as a technical barrier against the proliferation and recirculation of bacterially contaminated water.

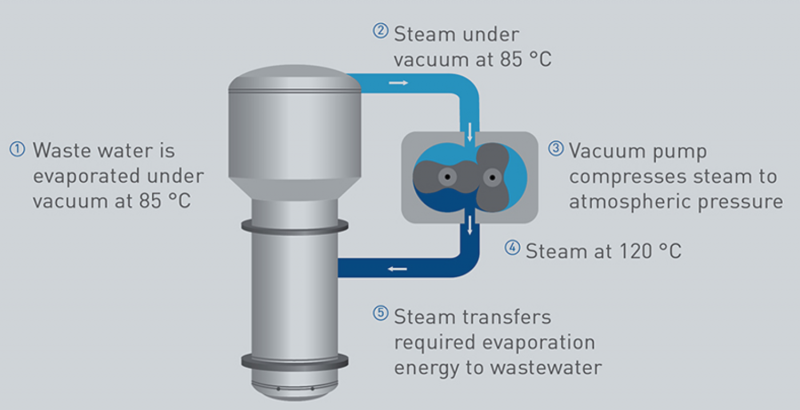

The thermal separation process serves this function during vacuum distillation. The goal is to separate the impurities from the clean water. To accomplish this, the wastewater is first heated to approximately 85°C in a vacuum during the evaporation process.

The presence of saturated water vapour at a temperature of over 80°C makes survival almost impossible for most microorganisms capable of reproduction, whether bacteria, yeasts, moulds or viruses.

Once the evaporation process is complete, the water vapour is condensed at normal pressure, so that the temperature of the water vapour mixture increases again to approximately 120°C. Not even stubborn viruses and spores can survive under these conditions. The resulting distillate is therefore completely free of germs.

Media

Taxonomy

- Saline Water

- Brackish Water

- Vapor Compression Distillation

- Multi-Effect Distillation

- Reverse Osmosis

- Sea Water Desalinisation

- Equipment & Machinery