UV Disinfection Technology Treats Process Water

Published on by Water Network Research, Official research team of The Water Network in Technology

Cott Beverages has been using Hanovia UV disinfection technology to treat process water used in the production process.

In an increasingly regulated and safety-conscious market, legislation such as the EU Directive for Bottled Water 98/88/EC (1998) drives the beverage industry to meet ever more stringent standards of quality.

Microbial growth due to contaminated water or ingredients can cause discoloration, off-flavors and shortened shelf-life. The threat of contamination is further increased as manufacturers respond to demands for less chemical additives and preservatives. Effective microbial disinfection of the whole process is therefore essential.

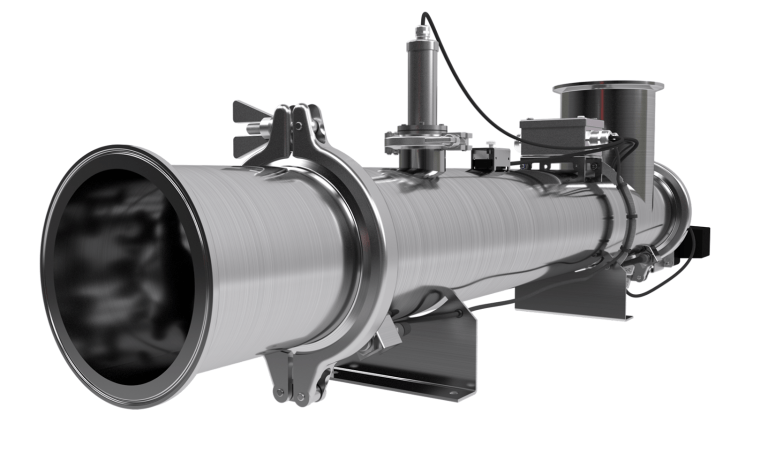

To meet this requirement, Cott Beverages has been using Hanovia UV disinfection technology to treat process water used in the production process. The company decided to use UV technology to ensure final product security prior to mixing and bottling and has been very satisfied with the performance of the UV systems.

Hanovia’s PureLine UV is an intelligent system that is optimized for the beverage industry to simplify the treatment of water, sugar syrup, brine and even reducing chlorine and ozone. Critically, there are no microorganisms known to be resistant to UV – this includes pathogenic bacteria such as listeria, legionella and cryptosporidium (and its spores, which are resistant to chlorination). Unlike chemical treatment, UV does not introduce toxins or residues into process water and does not alter the chemical composition, taste, odor or pH of the fluid being disinfected.

UV is used for both primary disinfection or as a back-up for other purification methods such as carbon filtration, reverse osmosis or pasteurization. Because UV has no residual effect, the best position for a treatment system is immediately prior to the point of use. This ensures incoming microbiological contaminants are destroyed and there is a minimal chance of post-treatment contamination.

UV disinfection systems are easy to install, with minimum disruption to the plant. They need very little maintenance, the only requirement being the replacement of the UV lamps every 9-12 months, depending on use.

Read more: Asia Food Journal

Media

Taxonomy

- Treatment

- UV Disinfection

- Filtration

- Technology

- Filtration

- water treatment

- Disinfection