Phosphorous Recovery From Wastewater

Published on by Water Network Research, Official research team of The Water Network in Technology

Municipalities and others concerned with wastewater treatment are recognizing the potential for extracting and reusing elements - such as phosphorus, energy and water - from wastewater.

Wastewater treatment involves more than just producing an effluent that is protective of human health and the environment.

Increasingly, municipalities and others concerned with wastewater treatment are recognizing the potential that exists for extracting and reusing elements such as phosphorus, energy and water, from wastewater, transitioning from traditional wastewater treatment models to water resource recovery centers.

This article looks at the role of conveyors in phosphorus recovery from wastewater.  Importance of Wastewater Phosphorus Recovery

Importance of Wastewater Phosphorus Recovery

Phosphorus is essential to all life and an important element for human nutrition. It plays multiple roles as a building block in the human body and, as a fertilizer, is an essential nutrient for healthy crop growth.

Without phosphorus, the basic cells of plants and animals, and even life itself, would not exist.

Traditionally, the global phosphorus supply is mined from a finite source of phosphate-containing minerals. As the world’s population grows, the demand for phosphorus continues to rise. However, as a limited and non-renewable resource, once consumed, phosphorus is difficult to reclaim.

Once phosphorus enters the human body as food, it is discharged back into the environment through wastewater. In addition to the phosphorus discharged annually by human waste, surface water can carry large amounts of phosphorus-laden runoff from fertilizer used on gardens, fields, and lawns.

Unless the phosphorus is recovered from wastewater during treatment, the net result is that phosphorus-rich effluent is discharged back into the environment.

Unfortunately, effluent containing excess phosphorus can be harmful to the environment. Phosphorus discharged in lakes and streams can cause toxic algae blooms, disrupting the ecosystem and threatening water supply.

In addition, phosphorus that is discharged in effluent is lost, contributing to the global depletion of this valuable resource. Due to these factors, regulators and wastewater treatment facilities are now moving aggressively to implement limits and methods for removing, recovering, and reusing phosphorus that would normally be discharged in effluent.  A Process for Wastewater Phosphorous Recovery

A Process for Wastewater Phosphorous Recovery

One approach to recovering phosphorus from wastewater is through the use of chemical precipitation. However, this approach is expensive and results in the production of excess sludge which requires further processing. Fortunately, Vancouver-based Ostara Nutrient Recovery Technologies Inc. has a different solution.

Ostara is a leading provider of a proprietary technology designed to assist cities and municipalities in managing excess nutrients through recovery, converting the nutrients into a Root-Activated fertilizer, sold as Crystal Green.

Ostara’s process for phosphorus recovery is based on a closed-loop solution where, instead of viewing wastewater streams as waste, Ostara sees a renewable resource that can generate revenue for treatment plants, while helping meet environmental regulations.

When wastewater treatment plants remove phosphorus from the wastewater, it concentrates in the solid residues produced. The nutrients are often recycled back into the wastewater when the solid residues are processed through anaerobic digesters, creating a new problem of nutrient-rich scale called struvite.

The struvite not only clogs pipes and valves, reducing flow, but requires costly maintenance and results in excess production of biosolids.

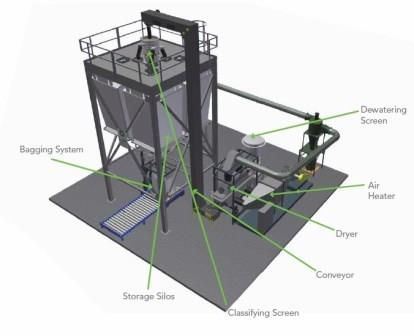

By controlling the crystallization of struvite in a fluidized bed reactor, Ostara’s Pearl technology recovers struvite (magnesium ammonium phosphate) in the form of highly pure crystalline pellets or “prills.”

Nutrient-rich feed streams are mixed with magnesium chloride and, if necessary, sodium hydroxide and then fed into the Pearl reactor where minute particles or struvite “seeds” begin to form. Like a pearl, these seeds grow in diameter until they reach the desired size – 0.9 to 4 mm – which is controlled by varying key parameters.

In a municipal wastewater treatment plant, up to 85 percent of the phosphorus and 40 percent of the ammonia load is removed from sludge dewatering liquid using this process and the resulting product is marketed as Crystal Green.

With Ostara’s technology, wastewater treatment facilities can recover phosphorus for reuse as an eco-friendly fertilizer, saving on chemical costs, reducing biosolids production, and creating a new revenue stream for the municipality.

Read full article: Powder & Bulk Solids

Media

Taxonomy

- Nutrients Recovery

- Waste Water Treatments

- Technology

- Nutrient Recovery & Reuse

- Water & Wastewater