Aerospace Technology for Modern Desalination Plants in Coastal and Arid Regions

Published on by Water Network Research, Official research team of The Water Network in Technology

The testing cycle of the mobile desalination plant is coming to an end. The plants are designed to provide fresh water to coastal and arid regions, primarily, of the Crimea, the Krasnodar and Stavropol Territories.

Source: Samara University Video (Print Screen); Via EurekAlert

Young specialists of JSC "Metallist-Samara" and scientists of Samara University are completing the testing cycle of a modern desalination plant. The project was implemented in the framework of the RF Government Resolution No. 218 "On Measures of State Support for the Development of Cooperation between Russian Higher Educational Institutions and Organizations Implementing Comprehensive Projects for the Creation of High-Technology Production". Besides, it was carried out within the purpose of import substitution.

The plants are designed to provide fresh water to coastal and arid regions, primarily, of the Crimea, the Krasnodar and Stavropol Territories. The desalination complex is designed for various parameters of the source water and can work in any sea with any salinity that is on our planet.

According to the developers, the applied layout solutions are unique, and when creating the key nodes and the elements, a unique experience of aviation and rocket engines designing and manufacturing, accumulated by the project participants, was used.

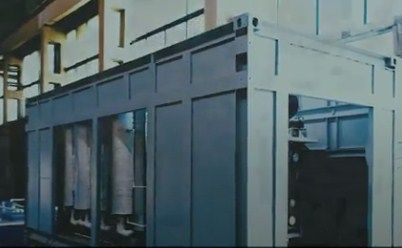

The specificity of the desalination plant being created is a high degree of autonomy and mobility. The whole complex is placed in two modular containers, which can be delivered by all types of trucks to anywhere in the world. This makes it possible to use the plant to provide fresh water for residential and industrial buildings as well as for remote infrastructure. It also can be used when eliminating the consequences of emergencies and disasters, accompanied by the destruction of water supply facilities.

Fresh water is obtained by vacuum distillation. A special steam compressor, which is the core of the entire system, was designed and manufactured for this purpose. It creates depression in several cascades of the plant, where evaporation of seawater occurs. Due to the vacuum boiling and evaporation occur at 50-60 degrees Celsius. The installation is designed in such a way that at each stage the output steam warms up the next cascade.

Such a solution provides the necessary autonomy and high energy efficiency of the complex. It does not require a heat-carrier. To operate the desalination plant, only a source of electrical energy is needed. While energy costs for its work are only 20 kWh, which is comparable to the consumption of five household direct-flow electric heaters.

The productivity of the first prototype of the plant is 2 cubic meters per hour. This is enough to fully provide fresh water to a standard nine-storey building or sanatorium, where at least 120 people live there at the same time (* - based on the established norms for the consumption of hot and cold water up to 12 cubic meters per person per month).

At present more than two more powerful models of a desalination plant are being developed, which are capable to produce 5 and 10 cubic meters of fresh water per hour. The modular design principle and the unique solutions that form the basis of this plant, opens the possibilities for increasing the productivity up to 100 cubic meters per hour.

The conducted developmental tests confirmed the claimed characteristics. In the near future, the plant should go to the Crimea for the experimental-industrial operation on the basis of one more partner of the project - Sevastopol State University.

Source: Samara University (Via EurekAlert)

Watch the full video HERE

Media

Taxonomy

- Treatment

- Treatment Methods

- Filtration

- Rural Water Supply & Sanitation

- Technology

- Filtration Solutions

- Filtration

- Desalination

- Filtration

- Sustainable Desalination

- Rural Area Water Supply

- water treatment

- Desalination