Biological Treatment of Manure - German Farm Case Study

Published on by Water Network Research, Official research team of The Water Network in Case Studies

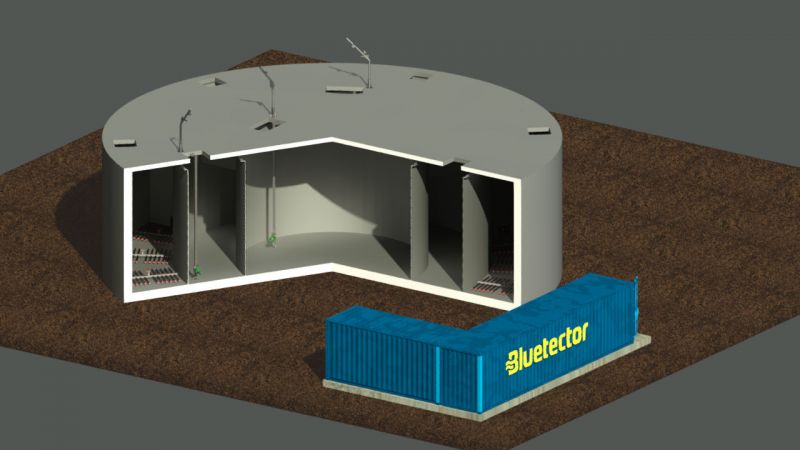

A farm in Lower Saxony with sow breeding, floor-feeding laying hens and biogas plant is installing a BlueBox Ultra for the treatment of manure from the Swiss agri-tech company Bluetector. The Bluetector plant will treat up to 26.000 gallons of manure per day.

Image source: Bluetector

The BlueBox Ultra has been specially developed for the biological treatment of manure and fermentation residues and works the same way as a municipal wastewater treatment plant. In the bioreactor of the BlueBox Ultra, the manure is converted into water, which contains only traces of nitrogen and phosphorus and is therefore ideally suited for irrigation. Since nitrogen and phosphorus are almost completely removed, only very small surfaces are required for application. The BlueBox Ultra eliminates the need for expensive and environmentally harmful manure transports, where manure sometimes has to be transported over hundreds of miles.

“I no longer want to have to carry out expensive manure transports,” explains farmer Jörn Ahlers, who runs a farm with a biogas plant in Lower Saxony. “I am convinced of the technology and user-friendliness of the BlueBox and I am confident that the system will go into operation on my farm this year.”

“In recent months we have presented our groundbreaking manure solution to many farmers and operators of biogas plants in North Rhine-Westphalia, Lower Saxony and Bavaria. The sale of the first manure treatment plant in Germany is of course an important milestone for us,” says David Din, CEO of Bluetector. “Our BlueBox enables farmers to convert their manure into water with a low-cost bioreactor without the need for costly and maintenance-intensive equipment such as reverse osmosis or centrifuges”.

Source: Bluetector

Media

Taxonomy

- Wastewater Disposal

- Reclaimed Wastewater

- Decentralized Wastewater

- Technology

- Wastewater Treatment

- Hog & Pig Farming

- Sustainable Farming

- Farms