Biological Wastewater Treatment Using Regenerated Activated Carbon Saves Disposal Costs

Published on by Water Network Research, Official research team of The Water Network in Technology

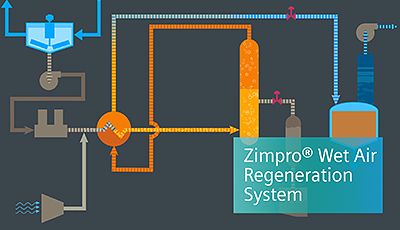

Finding an optimum way to treat wastewater in the oil and gas industry is a crucial issue. With its Wet Air Regeneration (WAR) system, Siemens is providing a method which works in combination with the powdered activated carbon treatment (PACT) system to recycle more than 90 percent of the required activated carbon, reliably destroy adsorbed contaminants, and convert sludge to ash. This avoids costly and laborious disposal to landfill.

Images by Siemens

Both a resource and a byproduct

Water plays a vital role in a whole range of different industries. The wastewater produced as a byproduct naturally has to be disposed of or treated responsibly. In upstream and downstream activities, water management is highly complex and has to comply not only with global standards but also with environmental legislation and the relevant regulations governing energy consumption. For this, Siemens Water Solutions offers its customers a particularly efficient and also environmentally sustainable process: the Wet Air Regeneration (WAR) system.

Less fresh carbon required

The solution is based on the world-class Zimpro Wet Air Oxidation (WAO) system, which oxidizes contaminants in an aqueous solution using oxygen as the oxidizing agent. By combining a WAR system with a biological PACT system, the amount of fresh carbon required can be substantially reduced.

No costly disposal

The PACT/WAR system can be used to treat the most difficult-to-treat wastewaters, which can then be discharged or even reused in the refinery. This is done by adding powdered activated carbon to the wastewater during the biological treatment step. The WAR system is not only used to regenerate the spent activated carbon, but the process destroys both non-biodegraded organics and biological sludge. Use of the combined system consequently avoids the need for costly sludge dewatering, disposal, and liability.

Source: Siemens

Media

Taxonomy

- Oxidation

- Carbon Filtering

- Biological Treatment

- Industrial Wastewater Treatment

- Sludge Treatment

- Water Treatment & Control

- Industrial Water Treatment

- Sludge Management

- Waste Water Treatments

- Polluted Water Oxidation

- Biological & Chemical Quality

- Biological Treatment

- Carbon

- Activated Carbon

1 Comment

-

Leave it up to a multinational to redo something from the past and try to make it sound new. 3 items to consider using this 1950's technology. 1. using microbes w/o machines or systems the current market cost is one penny per 30 gallons treated. No pathogens, all toxins are chelated with zero waste. This potable water can be put back into water supply. 2. The cost of transporting anything to a third world location will be very expensive. 3. This system does nothing to be part of the circular economy. The reality is homes can be in control of their own water, energy, foods. Best part is no more costly infrastructure. Each home or business can be their own ecosystem.