Curapipe May Have Answer to Aging Sewer Systems

Published on by Water Network Research, Official research team of The Water Network in Technology

Israel’s Curapipe company is offering an invasive “surgery for pipes.” Curapipe has worked to innovate the industry, offering what they call “automatic pig systems” that seal pipe leaks.

The company also offers trenchless sewer repair through an automated system called “TALR.”

By Jacob Maslow

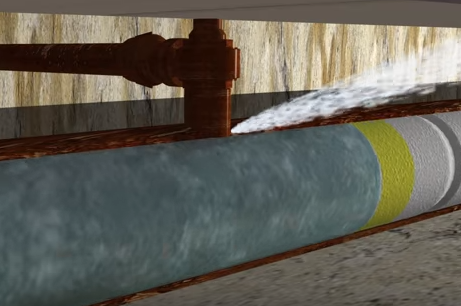

A sponge-like unit is used by the company to offer minimum disruption. Water pressure is used to detect leaks followed by an epoxy-based substance that seals the affected pipe. The company’s pilot program began in London in 2012 to help fix leaks in London’s sewer systems.

Aging sewer systems are a major problem around the world.

Israel, as a whole, has a national water system that is highly efficient. In 2009, it was announced that the NIS would invest 2 billion in a National Water System. The system would create new pipelines across 100 kilometers of water channels.

The system would connect five new desalination plants to supply up to 40% of the water to Israel’s residents.

Lining can be placed in the pipe to eliminate leaks and contamination while the old pipe remains. Small holes are drilled instead of a full excavation of the pipe. The repair allows the leak to be corrected without digging up city streets and

Read full article: The Times of Israel

Trenchless Automated Leakage Repair (TALR) technology

Trenchless Automated Leakage Repair (TALR) technology, developed and patented by Curapipe System Ltd., is designed to provide an internal pipeline leakage repair solution for multiple leaks in a water distribution network. TALR is best applicable for pipelines with heavy leakage from multiple leak sources within treatable pipe sections that are not required to be replaced due to an end of life situation.

TALR is applicable for a wide range of pipe materials. TALR is a stand-alone system that self-detects water leaks in a pipe and automatically repairs them.

An isolated pipe section of mains and service pipes is a requirement. Actual levels of leakage are measured before and after the repair.

The TALR solution is not intended to replace ongoing active leakage control services (i.e. “find & fix”) generally applied as a maintenance tool for leakage control, but as a complementary method for rapid bulk reduction of unsustainable leakage levels. TALR also works well in conjunction with network pressure reduction systems if already installed in the network.

Key Performance Features

Seals a variety of leak types both on water mains and connected service pipes.

Meets stringent health requirements for products that come into contact with drinking water.

Rapid deployment at a low cost.

75% reduction of overall leakage.

Long-term cure

Mode of Operation

A PIG train is launched into an isolated treated section of the water distribution network via an upstream fire hydrant or hot tap.

The PIG train contains a “compartment” consisting of Curapipe’s unique viscous curing substance wedged between two PIGs.

The substance operates under pressure and automatically detects and seals multiple leaky pinholes, joints, fittings and service connections.

The PIG train is typically extracted through a downstream fire hydrant.

The substance within the leakage area hardens and leaks are permanently cured.

Source: Curapipe

Attached link

http://www.youtube.com/embed/ys5jj9TMYugMedia

Taxonomy

- Technology

- Leakage Detection

- Leakage

- Infrastructure

- Leakage Reduction

- Infrastructure Management

- Pipes and Pipelines