Dow Chemical Unit Invests in Progressive Product Piloting

Published on by Water Network Research, Official research team of The Water Network in Business

Dow Water & Process Solutions, a business unit of The Dow Chemical Company, is demonstrating its dedication to research and development (R&D) through investment in progressive product piloting

The pilot program aimed to monitor the quality of the feedwater produced by the DOW Ultrafiltration system, in order to be able to provide support for Dow Water & Process Solutions' wide range of Ultrafiltration technologies, as well as reinforce its ongoing dedication to R&D and improvement of its products and solutions.

The data generated is used both to prove the success of its existing solutions and to validate and qualify new products before their launch into the market. The results of the piloting confirm sustainable and stable operation of DOW Ultrafiltration commercial modules as a pre-treatment for the Reverse Osmosis system downstream for more than 300 accumulated days, demonstrating their excellence and robustness in a real wastewater reuse application with relatively high organic content.

Verónica García, EMEA technical service and development manager, Dow Water & Process Solutions, explains, "This type of pilot experiment does not usually last more than few weeks, and therefore the long duration of the DOW Ultrafiltration piloting emphasizes the company's long-term commitment to product development and continued research."

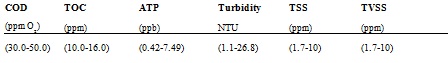

Table 1. Feed water quality parameters of the municipal Waste Water Plant

In order to provide real wastewater conditions, the pilot system was fed with secondary effluent from the Vilaseca (Tarragona-Spain) municipal wastewater treatment plant. Typically, due to wastewater feed quality and characteristics, the Reverse Osmosis system cannot be fed directly from the secondary effluent of the wastewater treatment plant without interruption. Therefore, to guarantee the required feed quality to the Reverse Osmosis system, a DOW Ultrafiltration SFP-2880 system was integrated upstream.

The autopsies carried out on the Ultrafiltration modules following the end of the piloting demonstrated the absence of broken or damaged fibers, as well as no reported loss in tensile strength and mechanical properties. Based on these test results, it can be concluded that DOW Ultrafiltration elements are an excellent pre-treatment for Reverse Osmosis systems. The permeate produced by the system downstream is suitable for a number of applications, such as for irrigation purposes, either for golf courses or for agriculture. Precisely, the agricultural sector represents 80% of water use in the country, so integrating advanced technologies such as DOW Ultrafiltration elements into the sector could help increase efficiency.

Economic solutions to achieve the highest standards

Another important finding from the study is the associated cost reduction resulting from the combination of DOW Ultrafiltration and DOW FILMTEC™ Reverse Osmosis technologies. For instance, DOW Ultrafiltration systems require a lower footprint when compared to other methods of conventional pre-treatment technologies, such as sand filtration. In addition, less chemical cleanings are required in the DOW FILMTEC Reverse Osmosis system downstream due to the more suitable feed water provided by the DOW Ultrafiltration system, resulting in longer membrane life, higher plant availability and lower replacement rate of cartridge filters.

Source: Zawya

Read More Related Content On This Topic - Click Here

Media

Taxonomy

- Ultrafiltration

- Reverse Osmosis

- Wastewater Treatment