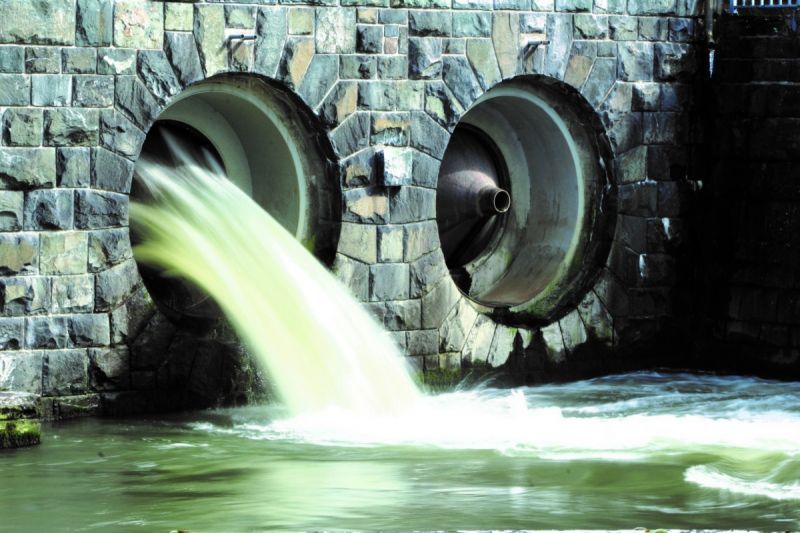

Electro-chemical Treatment of Industrial Wastewater

Published on by Anna Morynets in Technology

In recent years, the electrochemical methods of industrial wastewater treatment became more popular than chemical treatment.

It is due to a significant increase in prices of chemical reagents such as oxidizing agents, reducing agents, acids, alkalis, coagulants and flocculants. The other reasons to abandon chemical reagent treatment is the absence of secondary pollution of the treated water with anions and cations of salts, which makes the facilities environmentally safe; the purified water is reused in the production cycle, since its mineralization does not change, even reduced in some cases.

The methods used for comprehensive treatment of multicomponent wastewater with different qualitative and quantitative composition are adsorption and sedimentation of impurities. The treatment plants are compact and easy to operate.

The most common method of electrochemical treatment of wastewater uses active coagulants of aluminum or iron cations in the solution for ionization (electrochemical dissolution) of metallic anodes with direct current. Metal cations react with water molecules and form hydroxides with high sorption properties for heavy metals, organic compounds and other components of wastewater, and also reduce the amount of chlorine anions and sulfates.

Electrocoagulation with iron electrodes forms ferrous iron, and by adding coagulant, it reduces the amount of hexavalent chromium and other contaminants, such as petroleum, oils, surfactants, other organic impurities.

Electrocoagulation is easily controlled by adjusting electric current and metal ions transition between electrodes.

Upgrading electrochemical treatment plants requires an inspection according to safety standards and guides.

The main hazards of electrochemical treatment of wastewater, is the possibility of electric shock, electrolysis gas emissions, particularly chlorine, generation of fire and explosive dangerous mixtures of electrolysis gases (hydrogen) with oxygen and air, the possibility of generation of secondary hazardous substances by interaction of electrolysis components and wastewater.

Best wishes,

Ms. Anna Morynets

GlobeCore GmbH

Edewechter Landstraße 173,

Oldenburg-Eversten,

Germany,

26131

e-mail: energie@globecore.de

phone: +1713489375

Follow the latest news about GlobeCore equipment on our youtube channel english GlobeCore channel

Media

Taxonomy

- Electrocoagulation

- Electrodeionization

- Reclaimed Wastewater

- Industrial Wastewater Treatment

- Decentralized Wastewater

- Industrial Water Treatment

- Industrial

- Wastewater Treatment

- Wastewater Collection

- Industrial Water Reuse

- Industrial Water Managment

- Industrial Use

- Electrochemical Activation

2 Comments

-

Removal of heavy metals in industrial waste water by electrochemical methods is certainly useful. Eletrowinning of Copper is one good example.

Even common sewage too is known to be contaminated with heavy metals. Electrochemical will be more useful.

-

The efficiency of removal of pollutants is better. sludge quantity is reduced considerably.