Graphene Laminated Pipes Could Reduce Corrosion in the Oil and Gas Industry

Published on by Water Network Research, Official research team of The Water Network in Technology

Researchers at The University of Manchester and TWI have discovered ways of using graphene to prolong the lifetime of pipes used in the oil and gas industry.

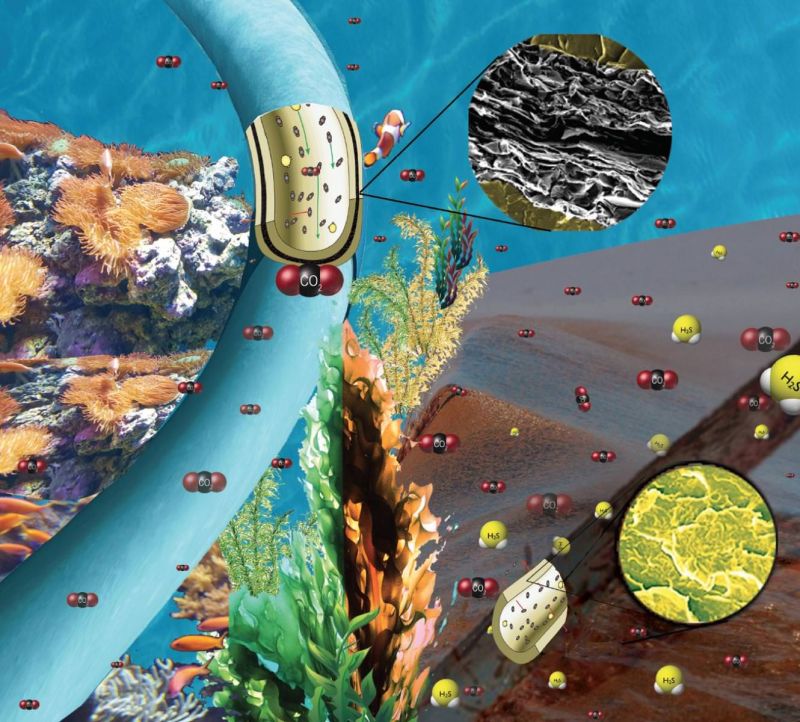

Published in Advanced Materials Interfaces, the team have found a way of incorporating graphene into a polymer liner used in pipes that transport crude oil and gas from the sea floor.

The pipes are generally made of internal layers of polymer or composite and external strengthening steel. Within these pipes, fluids may be at very high pressure and elevated temperature.

Image source: The University of Manchester

In situations where carbon dioxide (CO2), hydrogen sulfide (H2S) and water permeate through the protective barrier layer of the pipe, the steel may corrode causing the pipe to lose strength over time, leading to a risk of catastrophic failure.

The researchers found that if the graphene was mechanically mixed with the plastic, or if a single layer of graphene were applied, gases were still able to pass through.

However, by laminating a thin layer of graphene nanoplatelets to polyamide 11 (PA11) - a plastic often used in these liners - the team were able to produce structures that behave as exceptionally good barriers.

The multi-layered laminate structures were tested at 60oC and at pressures up to 400 times atmospheric pressure, and were shown to reduce CO2 permeation by over 90% compared to PA11 alone, while permeation of H2S can be reduced to undetectable levels.

Graphene is the world’s first two-dimensional material, flexible, transparent, more conductive than copper, and is known to block the passage of helium, the hardest gas to block.

Corrosion costs the oil and gas industry in the US alone $1.4 billion. This technology has the potential to extend the life of the underwater pipework and therefore reduce the time between repairs.

Professor Peter Budd, who led the Manchester team, said: “Graphene has many amazing properties, but it is not always easy to realise them on a large scale. Our work represents an important step in taking graphene out of the laboratory and into the real world.”

Dr Paul Woollin, Director of Research, TWI, said: “This research is an example of how TWI can work effectively with world leading universities through its Innovation Network, and draw on our cutting edge testing capability and in house experts, to identify unique and novel solutions to industry’s most challenging problems.

Graphene membranes such as these have the potential to open up vast new markets and revolutionise countless industrial processes, such as food packaging, water filtration and gas separation.

Reference : Thomas P. Raine et al. Graphene/Polyamide Laminates for Supercritical CO2 and H2 S Barrier Applications: An Approach toward Permeation Shutdown, Advanced Materials Interfaces (2018). DOI: 10.1002/admi.201800304

Source: The University of Manchester

Media

Taxonomy

- Technology

- Produced Water From Oil & Gas Industry

- Infrastructure

- Infrastructure Management

- Pipeline

- Pipeline Rehabilitation

- Oil & Gas

- Oil & Gas

- Graphene

- green infrastructure

- Pipes and Pipelines