How a Cling Wrap Made With Potatoes Will Solve the World’s Plastic Problem

Published on by Water Guardian Research in Entrepreneur

While working as an architect, Julia Kay had a realization that will, perhaps, end up changing the world. “I was excited by architecture because you’ve got the opportunity to design a world that you want to see,” she says. “But I realized that the construction industry is incredibly wasteful. There’s a huge amount of plastic waste, particularly in pallet wrap, and I was basically like, ‘Yeah, the world’s burning. I think I could be using my skills in a better way.’”

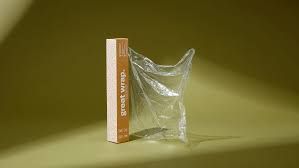

So when Julia put heads together with her now-husband, Jordy, who had similar anxieties about plastic from his career in wine production, they dreamed up an idea for a compostable cling wrap. The couple set up a manufacturing facility in Melbourne, Australia, and partnered with the chemical engineering team at Monash University to develop Great Wrap—a cling wrap made from potato waste.

So when Julia put heads together with her now-husband, Jordy, who had similar anxieties about plastic from his career in wine production, they dreamed up an idea for a compostable cling wrap. The couple set up a manufacturing facility in Melbourne, Australia, and partnered with the chemical engineering team at Monash University to develop Great Wrap—a cling wrap made from potato waste.

“After doing a lot of research, we found that potato waste has a high amount of starch and that there’s huge amounts of it [from feedstock] in every region,” says Kay. “There’s so much of this waste [in Europe, Australia, and the U.S.] that they’re putting it in paddocks to rot.”

Left to rot, potato waste emits methane. But when the chemical engineering team at Great Wrap extracts a compostable biopolymer from the potato starch, they’re transforming what would be a major pollutant into a useful product that will effectively leave no carbon footprint. When Great Wrap is composted, it only takes a maximum of 180 days to entirely decompose; petroleum-based wrap remains in our environment indefinitely.

The use of potato scraps also makes Great Wrap inexpensive to produce and sell—an essential factor in competing with plastic wrap. “If we make the perfect compostable polymer, but it’s 10 times the price [of plastic wrap], it’s not going to be scalable, and people aren’t going to want to buy it,” Kay says. Although Great Wrap is currently more expensive than the average cling wrap, in time, after they open their biorefinery, which will allow them to avoid outsourcing the polymer development and skip paying for the potato waste, the couple are confident that they’ll be able to offer their product at a lower price than petroleum-based wrap. “This isn’t a luxury good; it needs to be priced accordingly.”

Taxonomy

- plastic debris

- Plastic Ban

- Beat Plastic Pollution

- Plastic waste

- Plastic waste