How Essar Steel Algoma Keeps Slag from Dissolving into the River

Published on by Water Network Research, Official research team of The Water Network in Technology

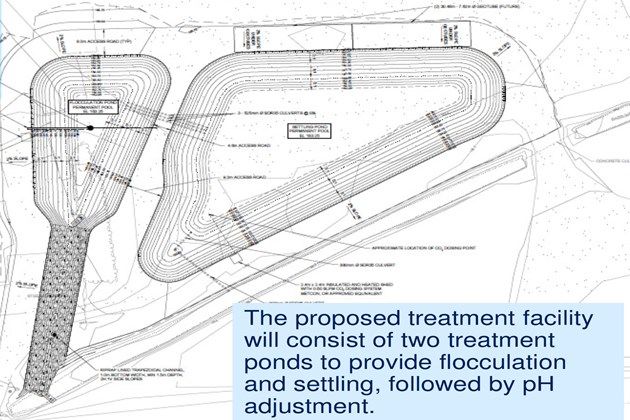

Essar Steel Algoma Inc. is preparing to build two treatment ponds to manage concentrations of dissolved iron in storm and surface water at its material storage and reprocessing site in Sault Ste. Marie.

"This is on the far side of our property. It's a development that's underway right now," says Brenda Stenta, Algoma's manager of corporate relations.

"We're treating dissolved iron, suspended solids that develop as a result of the dissolved iron, and we're neutralizing the pH [acidity or basicity] of the water," Fred Post, the steelmaker's manager of environment control.

"Since we're an iron and steel producer, we have iron in our byproduct materials such as slags that would dissolve in the water as it runs across. We're capturing that water," Post says.

Algoma has proposed building two treatment ponds: one for settling and the other for flocculation – the process by which fine particulates are made to clump together to facilitate their removal.

A drainage ditch in the northeastern part of Algoma's material storage and reprocessing site currently serves as a catchment for groundwater and surface water run-off.

Tests done by the steelamker since 2014 have repeatedly found that pH, dissolved solids and total iron require treatment.

"The plan is to add a polymer and an oxidation system so there'll be a little fountain here to oxidize the iron, bind it into a smaller particle. A polymer is added to bind the particles together, make them heavier and settle out of suspension. That will happen in the ponds."

"From there, we would have a carbon dioxide sparging system, which bubbles carbon dioxide gas through the water and neutralizes the pH," Post said.

Source: SOO Today

Media

Taxonomy

- Metals

- Heavy Metal Removal

- Industrial Wastewater Treatment

- Industrial Water Treatment

- Industrial Water Treatment

- Industrial Water Managment

- River Studies

- Environment

- Metals

- Heavy metals