Hydroflow - Limescale Prevention in Heating and Cooling Systems

Published on by Rashid Faruqi in Technology

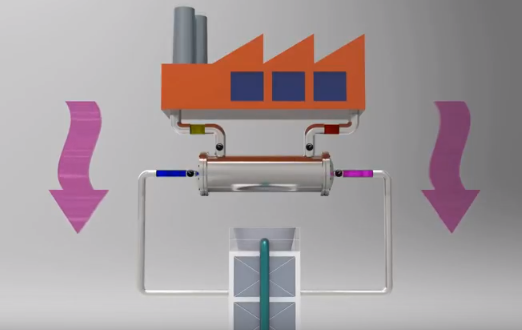

Hydro FLOW devices apply a pulsed frequency that travels throughout a water system and cause dissolved minerals to crystallize in the water so that they are filtered out.

The crystals cannot attach, and hard scale is prevented from forming on pipes and equipment.

The ±150 kHz frequency also disrupts biofilm and bacteria, which minimizes biological loading in a recirculating water system, such as a cooling tower.

Hydro FLOW is installed on the outside of a pipe of any material (plastic, metal, etc.) without cutting or modifications. Water can be used for longer cycles before disposal, with opportunities for reuse in irrigation or graywater systems which further conserves water and associated expenses.

Contact:

Attached link

http://www.youtube.com/embed/mPTpYyc8l0cMedia

Taxonomy

- Treatment

- Technology

- Filtration

- Consumption

- Water Resource Management

- water treatment

5 Comments

-

To remove the scale crystals and dirt, install a full flow air separator with coalescing media inside to "scrub " microscopic particles from the water. SweepCLEAR media is an easy, inexpensive retrofit coalescing media for existing air separators. Www.sweepclear.com

-

Hi Duane, the Hydroflow system works by causing particles of scale to form in the water rather than on structures such as pipes, heat exchangers, etc. These particles are smaller than a grain of sand and flow right through heat exchangers or other areas where the flow is restricted. The only time we have seen blockages is if there is already something hindering flow such as a flake off a pipe wall or some dirt in the system. The dirt or flake can then capture some of the grains and further impede the flow.

-

What about High And Low Pressure steam boilers? Is it equally good to be installed at ? If where it is installed over Inlet feed ? or some else place. Pl. respond.

1 Comment reply

-

We have units fitted on steam boilers all over the world. You are correct the units are fitted on the cold/cooler inlet feed. The reasoning for this is that you condition the water prior to heating it. The heating of the water is what causes the scale to drop out of suspension. The Hydroflow unit causes clusters of ions Ca+ CO3- in the flow and these then form CaCO3 crystals when the water is heated. The crystals tend to be quite spherical and do not adhere to surfaces well so any that aren't washed through can easily be cleaned out rather than having to use strong chemicals or physical attack!

I hope that helps.

-

-

Does that mean that all the minerals, calcium, etc stay in the flow? How does it prevent heat exchangers from plugging up? Just looking for clarification...

-

Great add, In Canada call 1-877-477-3569 for HydroFlow Canada or email: info@hydroflowcanada.com