IDE Technologies Launches MAXH2O for Increased Brine Recovery of Brackish Water Desalination Plants

Published on by Water Network Research, Official research team of The Water Network in Technology

IDE Technologies announced the launch of its brine desalter technology, MAXH2O, which aims to effectively reduce brine reject from brackish water desalination plants by ensuring a more durable and efficient process.

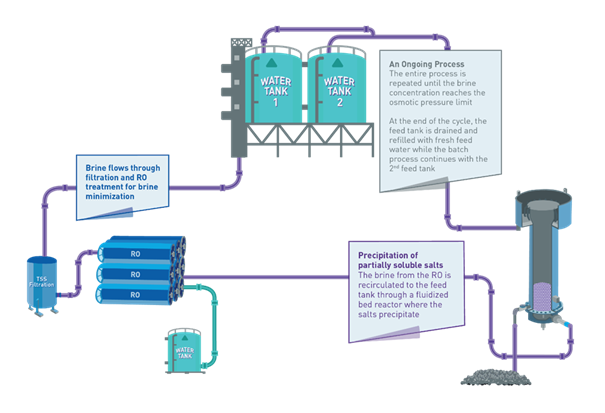

To increase brine recovery of brackish water reverse osmosis (BWRO) desalination plants, the MAXH2O desalter technology integrates a proprietary reverse osmosis (RO) system with an integrated salt precipitation unit, which together overcome the traditional limitations of brine recovery systems.

MAXH2O, Image source: IDE Technologies

The MAXH2O desalter also addresses other challenges such as scaling from sparingly soluble salts, and organic fouling and biofouling, without the use of additional chemicals. Increasing the BWRO plants recovery, thus reducing the amount of rejected brine from these desalination plants, helps to meet global water demands while reducing the environmental impact of brine.

The technology increases water recovery and benefits both municipal and industrial applications such as mining sites, power stations and cooling towers. Early pilots of MAXH2O on both existing and new BWRO desalination plants have shown an increased brine recovery of up to 98 percent.

Today, the presence of sparingly soluble salts such as Calcium Carbonate, Silica and Calcium Sulfate prevent BWRO and reuse plants from maximizing the potential of the BWRO plant and reaching the RO osmotic pressure limit, due to the risk of scale formation in the system and on the RO membranes.

As a result of the limitation caused by water chemistry, the recovery of BWRO plant is typically limited to about 80 percent. The MAXH2O desalter utilizes a semi-batch RO concept together with an integrated salt precipitating unit. Together these, in fact, eliminate the recovery limitation caused by the water chemistry and allow the RO system recovery to be pushed to the osmotic pressure limit at levels of up to 98 percent.

By using a semi-batch process, the flow through the membranes in the MAXH2O is increased, resulting in high cross-flow velocities inside the RO membrane feed brine spacer, reducing the effect of concentration polarization and the risk of scale formation.

The brine rejected from the RO membranes in each cycle passes through a fluidized bed crystallizer that gradually removes the sparingly soluble salts from the system – allowing the recovery to be maximized. This approach enables the MAXH2O Desalter to achieve up to 90 percent reduction in brine disposal, and overall recovery of up to 98 percent of the original feed flow.

"Reaching high recovery for BWRO systems has always been a challenge, which in many cases determined whether a project would be economically viable or not,” said Tomer Efrat, director of business development and head of IDE product line. “MAXH2O is definitely breaking the recovery limits known in the industry today, thus providing many more opportunities for both new installations and retrofitting existing facilities."

MAXH2O can be installed as a standalone system or connected to an existing BWRO plant as a tail unit on the brine stream in order to maximize the plant production while minimizing the brine discharge flow.

For additional technical information on MAXH2O, please visit, https://www.ide-tech.com/maxh2o

Source: GlobeNewswire

Media

Taxonomy

- Reclaimed Wastewater

- Reverse Osmosis

- Technology

- Wastewater Treatment

- Filtration Solutions

- Filtration

- Brackish Water

- Desalination

- Reverse Osmosis

- Brine Discharge Modeling & Analysis

- Filtration

- Desalination