Israeli Solar Desalination Process Cuts Energy Costs by 90%

Published on by Robert Brears, Founder of Our Future Water, Young Water Leaders, Mitidaption & Author (Springer Nature, Wiley) in Technology

Israeli startup TSD (Tethys Solar Desalination) plans to revolutionize the process with a low-cost, off-grid, scalable, and environmentally friendly module technology using only the power of the sun.

The most common method of reverse osmosis using membranes is costly, energy-intensive, high-maintenance, and environmentally problematic. It is best suited to mega-scale plants built on large tracts of high-value land near the ocean and consumes enormous amounts of electricity generated from fossil fuels. Then, the treated water has to be piped great distances to farms, industries, and households.

Israeli startup TSD (Tethys Solar Desalination) plans to revolutionize the process with a low-cost, off-grid, scalable, and environmentally friendly module technology using only the power of the sun – no fossil fuels and no carbon dioxide emissions.

Prof. Moshe Tshuva presenting TSD’s proof of concept. Photo: courtesy

TSD plans to have its first pilot site up and running in Israel by mid-2017, followed by possible pilots abroad. One of the four founders, Ze’ev Emmerich, told ISRAEL21c that TSD modules are attracting serious interest in China, the United States, and several other countries in Africa and Asia.

“At the World Economic Forum in Davos in 2015, it was agreed that water issues are going to be the biggest global challenge in the near future,” Emmerich said. “Though most of the world’s surface is covered with water, only 1 percent of that water is fit for consumption so there is enormous interest in desalination and decontamination in the developing world and in developed countries as well.”

TSD’s technology is the brainchild of cofounders Joshua Altman and Prof. Moshe Tshuva, head of the energy engineering department at Afeka College of Engineering in Tel Aviv.

Aiming to find a cheaper and more energy-efficient method than using photovoltaic (PV) cells to generate electricity for desalination plants, they developed a method using solar energy without PV cells — in fact without any electricity at all — for desalination and water treatment. Up to now, attempts at using solar energy in this way have been inefficient and have only been done on a very small scale.

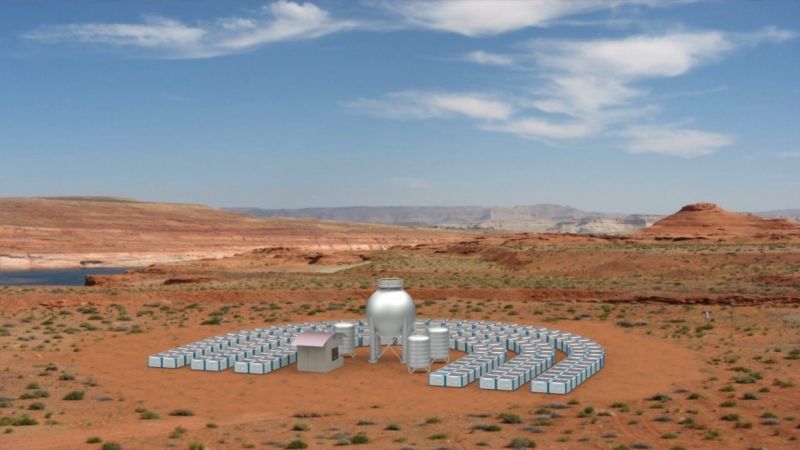

Their unique direct solar desalination technology can process up to 10,000 cubic meters of water per day for small to medium sites such as farms, factories and hotels, as well as remote villages, desert resorts and beaches, off-grid sites, and disaster areas. Solar heat evaporates the water, and the purified water vapor is collected and cooled back to liquid form.

TSD's proposed pilot system. Photo: courtesy

“It’s a highly efficient system, using each unit of energy from the sun several times,” Emmerich said. “It’s like creating micro-clouds and harvesting the water from them. We don’t touch the water; we just use what has been evaporated from the heat. In fact, we can use any source of residual heat to activate our process. Almost all industrial processes emit heat that is normally released to the atmosphere. We can use that heat for treating water.”

The modules, made mostly out of recyclable materials, are easily assembled near the end site, using locally available sources of water. The quantity and array can be changed as needed.

Headed by CEO Gil Toren, the company estimates that its technology cuts desalination energy costs by more than 90 percent and significantly reduces construction, operations, and maintenance costs.

Founded in 2014 with seed money from angel investors, TSD is based in Tel Aviv and is in the midst of a Series A fundraising round. “We are in contact with potential strategic partners and investors around the world,” added Emmerich, whose past activities include co-creating the Silicon Wadi documentary series on Israeli startups.

Source: Israel21c

Attached link

http://www.thetower.org/4183oc-israeli-solar-desalination-process-cuts-energy-costs-by-90/Media

Taxonomy

- Technology

- Water Security

- Energy

- Desalination

- Solar Desalination

- Sustainable Desalination

- Water

- Desalination

2 Comments

-

Yes. But if aridity is the problem in coastal regions, it is more effective to use a buoyant solar device. The salt redistributes with the currents. Please email for details.

-

This looks like a winner! Over the years I have designed and built several solar distillation devices. None were as sophisticated as this nor were mine scalable. I think this looks like a great investment.