Long-Term Membrane Performance with Continuous Use of Hydro-Optic UV Dechlorination

Published on by Water Network Research, Official research team of The Water Network in Technology

Evaluation of Long-Term Membrane Performance with Continuous Use of Hydro-Optic™ UV Dechlorination at Plant Bowen - Case Study by Atlantium

Plant Bowen, a 3,160 megawatt coal-fi red power station, in Cartersville, Georgia evaluated and installed a nonchemical dechlorination process, the Hydro-Optic™ (HOD) UV water treatment technology, to improve the overall quality of reverse osmosis (RO) feed water.

After three years of operation, the RO membranes are operating at the same level as new elements. Since the installation of the HOD UV technology the facility has reduced the use of SMBS and also minimized the frequency of micron fi lter replacement.

HOD UV Technology: Principles of Operation The HOD UV technology is a physical process for disinfection that exposes bacteria, viruses and protozoa to germicidal wavelengths of UV light, measured in nanometers (nm), to render them incapable of reproducing or further infecting a water system. Through UV oxidation, UV light can also destroy chemical contaminants.

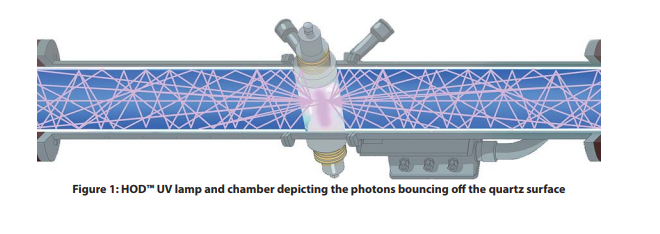

The technology measures four critical parameters including percent ultraviolet transmittance (%UVT), fl ow rate, UV lamp intensity (kW) and apparatus (consisting of Total Internal Refl ection and Dose Pacing) in real time to maintain a specifi ed UV dose. The system uses a proprietary Total Internal Refl ection (TIR) based design that when coupled with the comprehensive monitoring of critical parameters allows the system to achieve and maintain the specifi ed UV dose.

The system’s patented TIR technology, which is similar to fi ber optic science, recycles UV light energy within the HOD UV chamber. This is especially important given that in traditional UV systems metal adsorbs or “detracts” the UV dose the closer it gets to metal, whereas the TIR enhances the UV dose. Simply put, the UV photons are eff ectively lengthened and provide a greater opportunity to inactive microorganisms and decompose the free chlorine.

The core of the technology is its water disinfection/chlorine-decomposing chamber made of high-quality quartz surrounded by an air block instead of traditional stainless steel. This confi guration uses fi ber optic principles to trap the UV light photons and recycle their light energy. The photons repeatedly bounce through the quartz surface back into the chamber, eff ectively lengthening their paths and their opportunities to inactivate microbes.

Long-term Membrane Performance with HOD UV Dechlorination Plant Bowen uses a fi ve-year replacement cycle for the RO elements, the last installation occurred in March 2014. The HOD UV system was also installed and placed into continuous operation in March 2014. After three years of operation, the RO membranes are operating at the same level as new elements.

Prior to the installation of the HOD UV system the membranes were cleaned one to two times per month; with marginal improvement since 2014. However, what’s most interesting is that the driver for cleaning the membranes has changed.

After three years of operation, the membranes are only up to 34 psi diff erential pressure from the original 28 psi when they were put into service; indicating a longevity of the membrane elements that didn’t exist without the use of the HOD UV technology.

Comparatively, the pre-2014 membrane elements were running at a 50 psi diff erential pressure after three years of operation. Based on the 5-year replacement cycle for the RO elements, they are scheduled for a change out in 2019. If performance remains positive, the facility will evaluate the possibility of increasing the life span another year. This would result in an additional cost savings of $100K.

Performance of the micron fi ltration system has also been enhanced with the use of the HOD UV technology. In 2015 the 4 pre-RO micron fi lters were changed 6 times, then reduced to 4 times in 2016, and 2 times in 2017. The reduction in cleaning frequency has resulted in a net savings of $160K.

Read the full study in the attachment or download it from Atlantium

Media

Taxonomy

- Technology

- Membranes

- Desalination

- Membrane Technology

- Membrane Filtration

- Sustainable Desalination

- Utility Management

- Desalination