Mitsubishi Develops Energy-saving MBR

Published on by Naizam (Nai) Jaffer, Municipal Operations Manager (Water, Wastewater, Stormwater, Roads, & Parks) in Technology

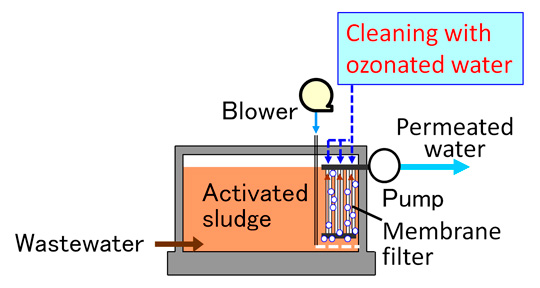

Mitsubishi Electric Corporation announced that it has developed a compact membrane bioreactor (Eco-MBR) that recycles municipal and industrial wastewater with low-energy consumption and dramatically increases the quantity of permeated water per membrane filter surface area (flux) by cleaning the filter with ozonated water

Commercial use in municipal and industrial wastewater reuse systems is envisioned in 2018.

The Eco-MBR achieves a high flux of 1.6 m3/m2/day and cuts the required number of membrane filters by intermittently cleaning the filters with ozonated water to efficiently remove organic substances for increased permeability. The Eco-MBR also features a compact footprint and reduces energy consumption by lowering the air flow rate that the blower uses to clean the membrane surface with bubbles.

The Eco-MBR achieves a high flux of 1.6 m3/m2/day and cuts the required number of membrane filters by intermittently cleaning the filters with ozonated water to efficiently remove organic substances for increased permeability. The Eco-MBR also features a compact footprint and reduces energy consumption by lowering the air flow rate that the blower uses to clean the membrane surface with bubbles. ![]()

In the conventional activated-sludge process, treated water is separated from activated sludge by sedimentation, which requires a large surface area and produces water quality not suitable for reuse. In the case of conventional MBRs, a sodium hypochlorite solution is commonly used to clean the membrane filtration, but oxidation power is relatively weak so high flux is not possible. Also, the process requires a large number of membrane filters. ![]()

Mitsubishi Electric will continue working toward commercial application of its Eco-MBR in municipal and industrial water-reuse systems, aiming at playing an important role in the effort to achieve water sustainability worldwide. ![]()

Mitsubishi Electric is jointly developing the Eco-MBR with professor Hiroshi Nagaoka of Tokyo City University's Faculty of Engineering. ![]()

Source: Mitsubishi Electric

Media

Taxonomy

- Membrane Bioreactor Systems

- Membranes