Multiphysics Analysis Advances Water Main Leak Detection

Published on by Water Network Research, Official research team of The Water Network in Technology

Toronto-based company Echologics, a division of Mueller Canada, Ltd., has developed unique acoustic technology for noninvasive leak detection.

by Valerio Marra

“Leaks make noise,” explained Sebastien Perrier, R&D acoustical scientist at Echologics. Perrier is a mechanical engineer who specializes in acoustics and vibrations, the coupling of structures, as well as signal processing. “The pipes talk and, if you listen, they’ll tell you where leaks are located,” he said.

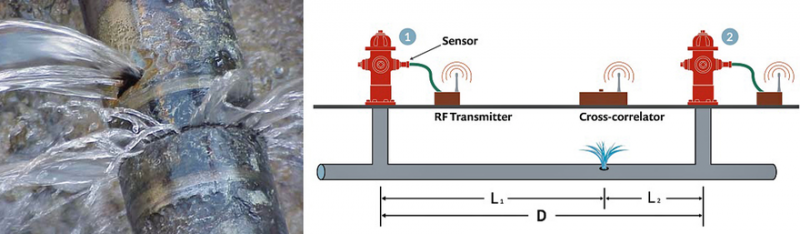

Echologics measures the time-of-flight of the sound using a correlation function and acoustic sensors set on the pipes or fire hydrants. If a leak occurs somewhere between two sensors, the leak is detected and the correlation result is used to determine the time difference the leak noise takes to reach each sensor. This provides the distance from the leak to each sensor once the speed of sound is known in the pipes under investigation (figure 1).

Fig 1: Left: Leaky pipe under investigation. Right: Schematic of leak detection setup. A leak is bracketed by two sensors whose distance is D. The leak sound propagates in both directions and a correlator measures the time it takes to reach each sensor. Based on the speed of sound in the pipes, the exact leak location can be found.

Echologics designs technologies that exploit this correlation to find leaks and to continuously monitor pipes for leaks. Examples of products include the LeakFinderST leak noise correlator (figure 2) and the EchoShore-DX pipeline monitoring system (figure 2).

Fig 2: The EchoShore-DX System turns existing fire hydrants into smart leak detection technology.

Echologics correlators allow field specialists to investigate leaks in a variety of pipes using transmitters, sensors, and a user interface that can be set up on a standard laptop. Since correlators monitor leaks as they grow, this acoustic technology can detect even very small leaks in the early stages of formation, saving municipalities’ money and time.

The technology powering these products requires a precise understanding of the speed of sound in different types of pipes. It is material dependent, proportional to the stiffness of the pipe, and influenced by the pipe geometry.

“The key was developing technology sensitive enough to make leak detection possible in PVC pipes,” explained Perrier. Plastic has high attenuation and dampening compared with metal. Even trickier is the fact that older water systems originally made with cast iron pipes are being repaired — in individual segments — with plastic.

Read Full Article: Sensors Mag

Media

Taxonomy

- Sensor Systems

- Leakage Detection

- Leakage

- Infrastructure

- Leakage Reduction

- Infrastructure Management

- Multi-Sensor Pipelines

- green infrastructure