Poredesigner Improves Protein Channel Design for Water Treatment, Bioseparations

Published on by Water Network Research, Official research team of The Water Network in Academic

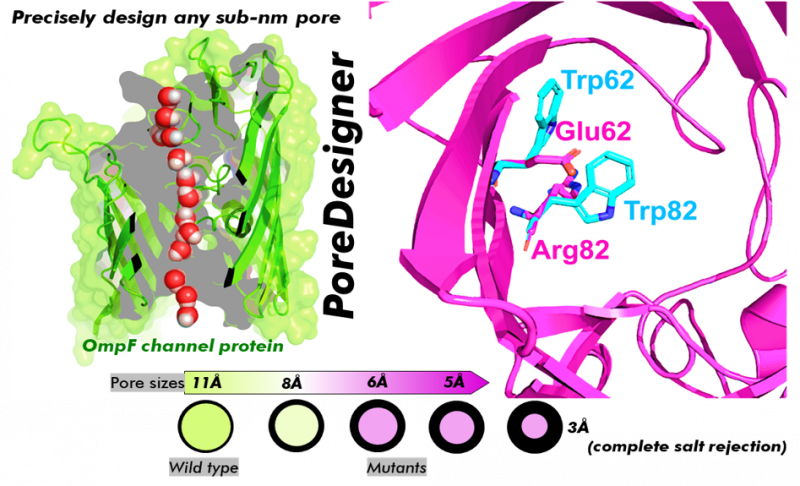

PoreDesigner, a fully automated computational workflow process for altering the pore size of a bacterial channel protein, is the result of a collaboration between researchers from Penn State and the University of Illinois at Urbana-Champaign.

This process enables assembly of the proteins into artificial membranes for precise sub-nanometer scale separation of solutes of marginal size difference, which can improve water purification and bioseparations.

Figure outlining the basics of PoreDesigner's workflow for altering the pore size of a bacterial channel protein. (Image by Manish Kumar/Penn State)

PoreDesigner provides a design procedure for tuning the pore size of the channel protein OmpF, found in the outer membrane of E. coli bacterial cells. Biological membranes are an ideal model for synthetic membranes, because their pores are all exactly the same size, which provides high productivity combined with high selectivity — only molecules of the desired size and shape get through. The biological membranes have various protein channels that transport water, ions and small molecules between cells. They also block out impurities that cannot fit through the pores.

"It is difficult to create uniformly distributed, equal pore sizes in artificial membranes like the polymer ones used in industry, but if we could, water would go through faster and, at the same time, block molecules larger than the pores," said Ratul Chowdhury, doctoral candidate in chemical engineering, co-advised by Manish Kumar, associate professor of chemical engineering and Costas Maranas, Donald B. Broughton Professor of Chemical Engineering. "The natural pores we began with were larger than one nanometer. We engineered them to be subnanometer sized, which are more useful for separating certain commercially important molecules."

Designing pore sizes with precision in the range of or less than 1 nanometer is an issue for artificial membranes. At this size or smaller, slight variations may seem insignificant. However, to completely reject certain impurities such as salt, the pores need to be of the order of 0.3 to 0.4 nanometers.

"The OmpF protein was chosen because it is a more structurally stable molecule than the more widely studied aquaporin molecules, so the hypothesis was that if we make changes to the original OmpF molecule to make its pore size smaller it would still retain its structural stability," Chowdhury said. The researchers published their results in Nature Communications.

The pore size of OmpF is 11 angstroms, and the research team reduced the pore size by systematically filling in the pores with hydrophobic, or water-repelling, amino acids.

"From experiments, we found that we could efficiently reject salt with these proteins when put in a membrane assembly," Chowdhury said.

They also found that it is possible to reduce the pores to specific sizes, ranging from 0.3 to 1nanometer, to reject various impurities, creating custom angstrom-scale sieves. The team calls this overall initiative of targeting angstrom — one tenth of a nanometer — scale pores by design, the Dial-an-Angstrom initiative.

The PoreDesigner process also produces water channels that permeate faster than biological water channels. This is due to the more hydrophobic inner pore walls of the redesigned OmpF protein preventing the water from interacting with the pore wall, enabling faster transport of water.

There are multiple benefits to the PoreDesigner workflow and the resulting channels. This process saves energy because these water channels are more selective and productive. The PoreDesigner also enables precise pore sizes for bioseparation processes that are extremely difficult, such as separating glucose and fructose, and sucrose from glycine. In addition, because of its effectiveness at filtering out salt, PoreDesigner could potentially enable coastal communities to have a reliable source of water.

Beyond water purification, the researchers are trying to engineer the pores to reject protons while just allowing water to pass through. If successful, this could improve diffusion-weighted Magnetic Resonance Imaging where engineered transport proteins are beginning to be used.

"The higher the flow rate of water through the channels, the better the resolution of the MRI image," Chowdhury said. "We have shown that our OmpF designs already permeate water at an order of magnitude faster rate than any channel reported, so our designs could be very important for medical imaging."

Chowdhury added that PoreDesigner bears promise for application in space flights and future space habitats for filtering urine to get pure water, which would be very important for using and recycling scarce water supplies.

"Ratul won the Best Paper award in 2018 for this work from the Department of Chemical Engineering and was recently selected for the North American Membrane Society Student Fellowship," said Kumar. "These accolades are well-deserved as Ratul was the driving force for this work and really owned all aspects of the project."

Other researchers from Penn State on this project are Tingwei Ren, doctoral candidate in chemical engineering; Matthew Grisewood, research assistant in chemical engineering; and Jeevan Prabhakar, an undergraduate researcher in chemical engineering. Kumar and Maranas co-led the research. Manish Shankla, doctoral candidate at UIUC; Karl Decker, research assistant at UIUC; and Aleksei Aksimentiev, professor of physics at UIUC, also participated in the research.

A Faculty Early Career Development (CAREER) Award from the National Science Foundation supported this work.

Source: PennState University News

Media

Taxonomy

- Treatment

- Ultrafiltration

- Produced Water Treatment

- Industrial Wastewater Treatment

- Drinking Water Treatment

- Membrane Bioreactor Systems

- Water Treatment & Control

- Industrial Water Treatment

- Waste Water Treatments

- Purification

- Filtration

- Technology

- Filters

- Membranes

- Filtration Solutions

- Industrial Water Treatment

- Polymeric Membranes

- Membrane Technology

- Membrane Filtration

- Proteins

- water treatment

- UF membranes/cassettes for waste water treatment MBR