Predictive Analytics Data Helps Spray Aeration Technologies Work More Efficiently

Published on by Water Network Research, Official research team of The Water Network in Technology

Medora Corporation and Aqua Metrology Systems have teamed up to deliver a complete trihalomethane (THM) compliance solution for water utilities to manage harmful disinfection byproducts (DBPs).

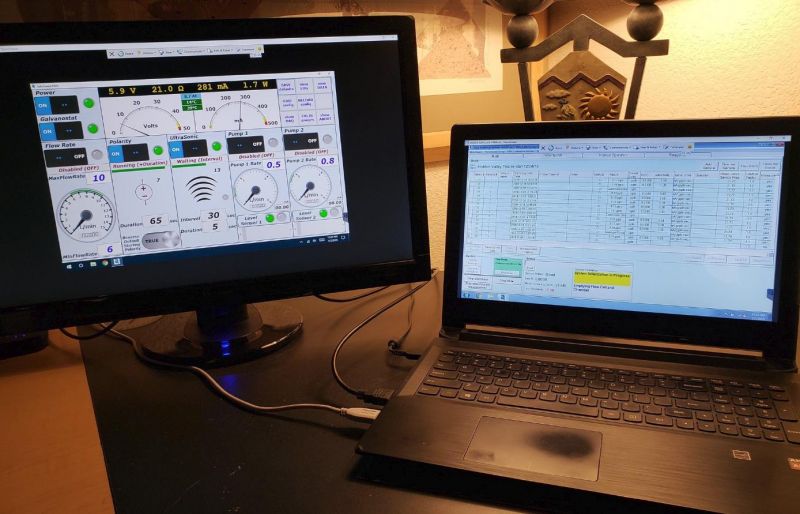

Image by Aqua Metrology Systems

Medora, a market leader in THM removal spray aeration technologies with more than 200 installations, has announced that it will be using AMS’ online THM and THM Formation Potential analyzer, THM-100™, to provide real-time and predictive analytics data to design and operate its spray-aeration system more efficiently, thereby saving utilities high treatment costs while ensuring compliance with regulatory standards.

THM levels in a water treatment system can change rapidly and are highly influenced by changes in raw quality and water age. Without real-time and high-frequency actual and predictive data on THMs across their networks, water treatment companies face the risks of undertreating their water or the substantial costs they incur from over-treatment.

“Real-time THM formation potential data on both treated and raw water ensures maximum advantage is taken of aeration systems to deliver compliant water to the consumer,” said Rick Bacon, CEO of AMS. “Medora is the first THM removal solutions provider to embrace real-time monitoring to drive its intelligent aeration and mixing systems. The integration of real-time water quality data and advanced treatment system is a prime example of an intelligent water treatment system designed for the benefit of the utility and their customers.”

“The first step in solving a problem is to understand the problem,” said Cliff Tormaschy, CEO of Medora Corporation. “AMS’ unique capability to develop real-time intelligent predictions of THM formation will enable the design of a cost-effective remediation process and ensure that we offer clients intelligent data-driven solutions for achieving THM compliance.”

Bryan Galvin, Wells and Reservoir Supervisor for the Town of Gilbert, Arizona, who has been using the high-frequency online THM data from AMS’ THM-100™ since October 2017 to manage DBPs within the town’s extensive and complicated network said, “The online THM analyzer has acted as the ‘brains’ of the THM remediation efforts in place across our reservoirs and pumping stations. Having access to this type of quality data is very comforting and has allowed for the operational certainty we did not have before. With this data, we have been able to develop a fully automated air stripping and aeration system because it provides rapid assessment of the impact of ever-changing THM levels and validation of our remediation process. Going forward, real-time THM data will confirm our Medora Corporation THM Removal System operates as

needed, resulting in significant cost-savings while ensuring compliance with regulatory standards.”

Source: Aqua Metrology Systems

Media

Taxonomy

- Chemical Treatment

- Biological & Chemical Quality

- Technology

- IT

- Data Management

- Chemical Analysis

- Water Supply

- Water Utility

- Solutions

- water treatment

- Data Management

- Data & Analysis

- Distribution