Robotic Crawler Delivers High-resoultion Data for Bar-wrap Pipe Inspection

Published on by Water Network Research, Official research team of The Water Network in Technology

Tehachapi-Cummings County Water District (TCCWD) gave Pure Technologies the opportunity to showcase its new, higher resolution 24-detector PureRobotics electromagnetic inspection platform on its Water Importation Mainline Pipeline, a critical main constructed of bar-wrap pipe.

This was an improved version of the successful 12-detector array, providing more accurate estimates of distress and a detection limit appropriate for locating defects half the size of the previous version of this technology.

In spite of minor challenges, the 7.2 mile inspection of the main went off without a hitch, and the third generation robotic crawler returned higher resolution assessment data that TCCWD will use in planning for the future management of their pipeline network.

Overview of Bar-Wrapped Pipe (BWP)

The BWP used in the 30-inch Water Importation Pipeline was installed in 1972. BWP is comprised of a welded steel cylinder and mild steel reinforcing bars wrapped around the cylinder under tension. An inner concrete lining and outer mortar coating provide corrosion protection for the steel components. Deterioration can begin on the bars or on the cylinder, and the bedding around the pipe is important for the structural capacity of the pipe. The integrity of the mortar coating is essential to protect the steel against corrosion and premature failure.

TCCWD has had several failures on this pipeline since its installation, and decided to take action. While the pipeline is over 30 miles long, Tehachapi is first focusing on the 7.2-mile BWP section that brings the water from the aqueduct to Pump Station 1.

As part of the condition assessment, Pure Technologies also performed transient pressure monitoring, three-dimensional, nonlinear Finite Element Analysis (FEA) structural evaluation, and material sampling of the pipeline.

SmartBall® leak and gas pocket survey conducted first

In addition, in the 2015 shutdown season Pure Technologies ran a SmartBall® leak and gas pocket detection survey through this pipeline, the results of which indicated the presence of a small leak and entrained air potentially getting trapped in the pipeline.

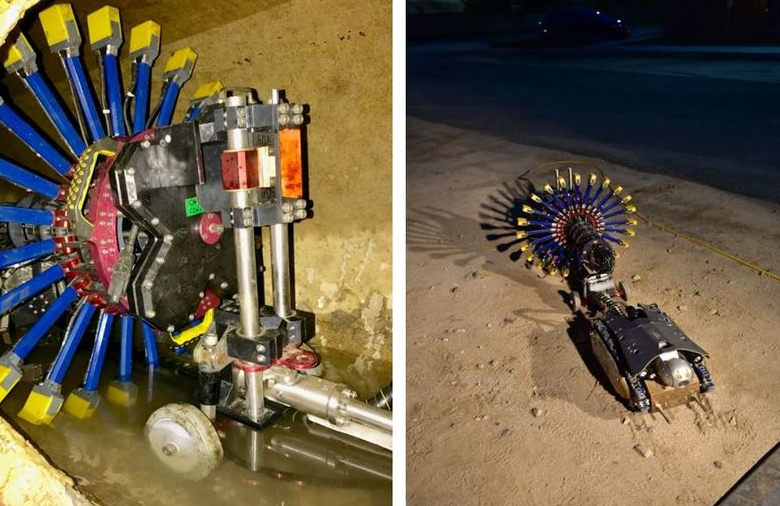

In late 2016, Pure Technologies completed the assessment by running an enhanced electromagnetic inspection with the PureRobotics' new 24-detector array, a marvel in design and engineering. The PureRobotics electromagnetic inspection platform is a unique, non-destructive method of evaluating the current condition of the bar wraps and steel cylinder in a BWP.

First electromagnetic survey and condition assessment with PureRobotics 24-detector array

The electromagnetic survey was the first EM survey and condition assessment of this main.

PureRobotics was selected as the primary inspection platform over the PipeDiver® due to the requirement to understand the lining condition and other information only made possible with an internal CCTV survey.

The robotic transporter is equipped with a high-definition CCTV camera to deliver a live video stream from inside the pipe. With the new generation of robot, the speed is doubled to 85 feet per minute, which greatly improves efficiency in the field, a huge benefit during time-critical shutdowns.

Results

Over the 7-day inspection, the electromagnetic and visual survey spanned an overall distance of approximately 7.2 miles. The survey utilized six (6) insertion locations to inspect the pipeline, for which TCCWD installed new access ports.

Of the 986 BWPs assessed, one (1) pipe exhibited an electromagnetic anomaly indicative of broken bar wraps. Three (3) pipes contained an anomalous electromagnetic signal not characteristic of broken bars, which correlated to visual CCTV observations of cylinder corrosion.

Overall, the pipeline contains no pipes beyond the yield limit within the given operating parameters, and as such, the pipeline is in serviceable condition from a structural capacity standpoint.

Overall, Pure Technologies and TCCWD were pleased with the delivery and operation of the enhanced PureRobotics inspection platform, which exceeded expectations.

Going forward, the assessment data based on the inspection and analyses performed on the BWP will be used in planning for the management of their pipeline network.

Source: Pure Technologies

Media

Taxonomy

- Technology

- Pipes Design

- Urban Water

- Leakage

- Infrastructure

- Urban Water Infrastructure

- Infrastructure Management

- Pipes and Pipelines