Solid-State Technology Answers Common Maintenance Problems

Published on by Mitch Hansen, E-Marketing Specialist at AquiSense Technologies in Technology

UV-C LED systems reduce the need for cleaning and maintenance issues for UV disinfection units.

Conventional UV lamps have been treating water for several decades with some changes in design and technology. Some advancements in UV disinfection technology attempt to mitigate the need for cleaning, maintenance and frequent part replacement. Although these advancements can reduce maintenance needs, nothing can change the fact that these lamps are analog technology. Solid State semiconductors have advanced to the point where commercial UV-C LEDs are available. These devices use the same physical disinfection methods as traditional tube lamp devices; however, UV-C LEDs have several advantages. UV-C LEDs are currently being implemented into disinfection devices making plug-and-play UV disinfection possible.

AquiSense’s PearlAqua™ - the world’s first commercial UV-C LED disinfection system is paving the way for safer treatment technology and superior performance. This millennial technology jumps over the hurdles of conventional mercury UV systems such as constant maintenance, fragile components, on cycle lamp decay, high operating temperatures, etc.

AquiSense’s PearlAqua™ - the world’s first commercial UV-C LED disinfection system is paving the way for safer treatment technology and superior performance. This millennial technology jumps over the hurdles of conventional mercury UV systems such as constant maintenance, fragile components, on cycle lamp decay, high operating temperatures, etc.

Minimal Maintenance Needs

With conventional UV tube systems there are several parts needed for the system to function properly: UV lamp, quartz sleeve, reactor body, control box, ballast, sensors, etc. The UV lamp requires annual replacement and safe disposal due to the mercury content. The fragile quartz sleeve and needs monthly monitoring and cleaning to prevent fouling. With the PearlAqua there is no tube, no quartz sleeve, and no ballast. The LEDs emit light through a small quartz window which needs annual monitoring and possible cleaning. Everything is integrated into the system allowing for a true plug-and-play, single device, disinfection system.

Zero Temperature Influence

UV mercury lamps require 10 - 15 minutes warm up time and operate at temperatures from 100 - 600 C. This heat is passed on to the quartz sleeve promoting biofilm growth on or around the sleeve making for more frequent system maintenance. UV-C LEDs are similar in function to visible LEDs. On the front face of the LED only light is shown; all the heat created is emitted through the back of the LED. The PearlAqua takes advantage of this by incorporating a heat sink into the design to pull heat away from the LED device, prolonging its life. No heat is transferred to the water or the quartz window lessening the possibility of fouling.

Lower Energy Consumption

Lower Energy Consumption

Conventional lighting methods, whether in a tube T.V. or standard 60W bulbs have been seen as inefficient and energy hungry since LED options became available. This pattern is repeated in the switch from conventional UV lamps to UV-C LEDs. Conventional UV lamps use 110 – 240 V to operate and with today’s technology, these lamps still require warm up time prior to treating water. The PearlAqua on the other hand, requires 6V of power to operate. Because LEDs reach peak power instantaneously, the system can be switched on only when water is running through it allowing for 80% reduction in energy used.

No Advanced Lamp Decay

Warm up time is not just important for energy use; it also effects the lifetime of conventional lamps. These lamps require time to warm up and cool down preventing the amount of times you can use it per day. Typical mercury lamps can be switched on no more than 4 times a day without effecting the life of the lamp. Each switch on/off decays the lamp, and shortens its lifespan by a fraction. UV-C LEDs are not effected by on/off switching allowing for instant on/off throughout the day without any effect on lifetime decay.

Hazard Free

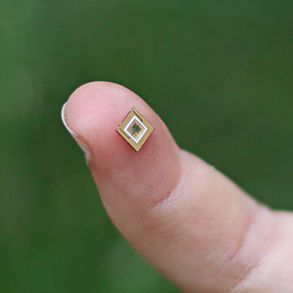

Conventional tube lamps contain mercury in each tube. These lamps tend to be fragile and can break during cleaning or replacement, causing exposure to the mercury. Even when a lamp is successfully removed there is still the issue of disposal. The PearlAqua uses the UV-C LEDs lamp, UVinaire™ which makes replacement safer and easier. After the 10,000-hour life, the UVinaire lamp can be disposed of easily. The usage accumulation of 3 hours/day allows for a 9-year life for the UVinaire.

The maintenance issues surrounding conventional tube lamps have more to do with the type of bulb used than the reactor or the added technology. No matter how advanced the technology is surrounding tube lamps, it is still dated analog technology at its core. UV-C LEDs used in the PearlAqua are solid state semiconductors making it the most advanced water disinfection system to date. Advancements in technology decreases end user needs for maintenance making UV-C LED systems, like the PearlAqua a true plug-and-play system that will save time and money year after year.

Source: Aquisense Technologies

Media

Taxonomy

- UV Disinfection

- Innovation

- Maintenance