The AI/ML revolution in sewer inspection pipeline condition assessment

Published on by Water Network Research, Official research team of The Water Network in Case Studies

Tim MedearisFebruary 10, 2025

Tim MedearisFebruary 10, 2025

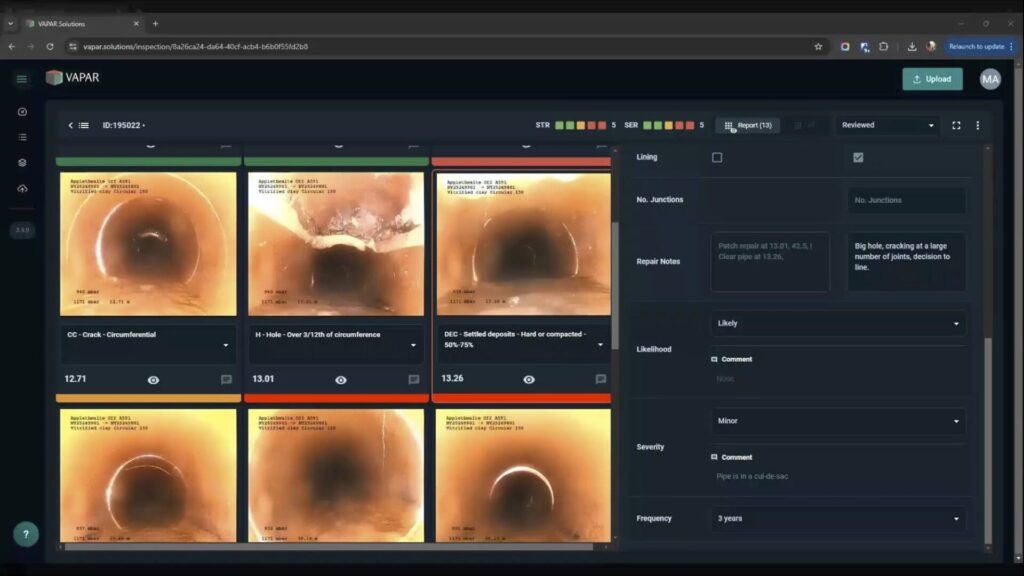

Sewer pipeline assessment can be a dirty job. To make it easier, Autodesk’s Tim Medearis and VAPAR’s Michelle Aguilar teamed up at Autodesk University to show customers How AI/ML in Info360 Asset Can Assist in Sewer Pipeline Condition Assessment and Management. If you’re at all interested in Artificial Intelligence for the water industry, this presentation about how Artificial Intelligence and Machine Learning is making CCTV sewer inspections easier is probably one of the best and most straightforward use cases for AI in water.

The challenge of aging sewer infrastructure

Sewer pipelines are critical – yet often overlooked – components of urban infrastructure. With millions of miles of pipelines worldwide, utilities face immense challenges maintaining these systems to prevent overflows, blockages, and environmental damage. Traditionally, the process of assessing sewer conditions relies on closed-circuit television (CCTV) inspections, an expensive, time-intensive method requiring expert interpretation of video footage.

As pipes age and budgets tighten, utilities must innovate. AI and Machine Learning (ML) offer transformative potential, streamlining sewer condition assessments and enabling data-driven decision-making with both a high-level and zoomed-in view. This blog explores how Autodesk’s Info360 Asset and VAPAR’s AI/ML solutions work together to modernize sewer infrastructure management, reducing costs and enhancing efficiency.

The current state of sewer infrastructure

The most recent ASCE Report Card for American Infrastructure gave the US a C rating (up from a D+) for its wastewater infrastructure:

- The U.S. has 700,000–800,000 miles of public sewer mains and 500,000 miles of private lateral sewers, serving 240 million Americans.

- Aging pipes and deferred maintenance contribute to an estimated 900 billion gallons of untreated sewage discharged annually.

- The EPA reports an investment gap of $105–$150 billion from 2016 to 2025, with pipes comprising 80–85% of total needs.

- The nation’s 16,000 wastewater treatment plants are functioning, on average, at 81% of their design capacities, while 15% have reached or exceeded it.

These staggering numbers underscore the urgent need for improved sewer inspections and maintenance strategies.

Traditional pipe inspection: challenges and limitations

The reasons why sewer inspections are conducted is very straightforward:

- Proactive: Preventative maintenance to avoid incidents

- Tactical: Targeting high-risk areas

- Reactive: Addressing immediate failures like blockages or overflows

- New adoptions: Ensuring new or rehabilitated pipes meet design standards

The way this typically works is that CCTV cameras – mounted on crawler units – captures footage of pipelines. Operators simultaneously must navigate equipment, manage traffic, and document defects based on regional standards. However, this manual process can be error-prone and time-consuming, with 40% of defects often missed during field sewer inspections.

When AI watches the video for you, you can turn an enormous task into a short review.

How AI/ML transforms sewer condition assessment

VAPAR addresses these challenges by leveraging AI and computer vision to automate defect detection. Here’s how it works:

- Image recognition technology: VAPAR’s AI detects structural and operational defects such as cracks, roots, and deposits with precision.

- Seamless integration: Utilities upload inspection videos, which VAPAR processes using global reporting standards. Results are available in minutes.

- Decision support: AI-generated reports suggest repair strategies, helping utilities prioritize maintenance based on severity and budget constraints.

Info360 Asset: enhancing asset management

Autodesk’s Info360 Asset takes sewer management to the next level, integrating with VAPAR for a holistic approach to asset management. As a cloud-based solution, Info360 Asset provides real-time collaboration and analysis, offering:

Taxonomy

- Combined Sewer

- Infrastructure

- Condition Assessment

- Sewer Networks

- artificial intelligence

- Leak Detection and Inspection

- United States