Thin-Film Graphene Nanocomposite to Improve Desalination Processes

Published on by Water Network Research, Official research team of The Water Network in Technology

A team of Researchers from Australia and Egypt have created a new thin film nano-composite (TFNC) membrane to address the issues surrounding water flux, salt rejection and biofouling in these processes.

By Liam Critchley

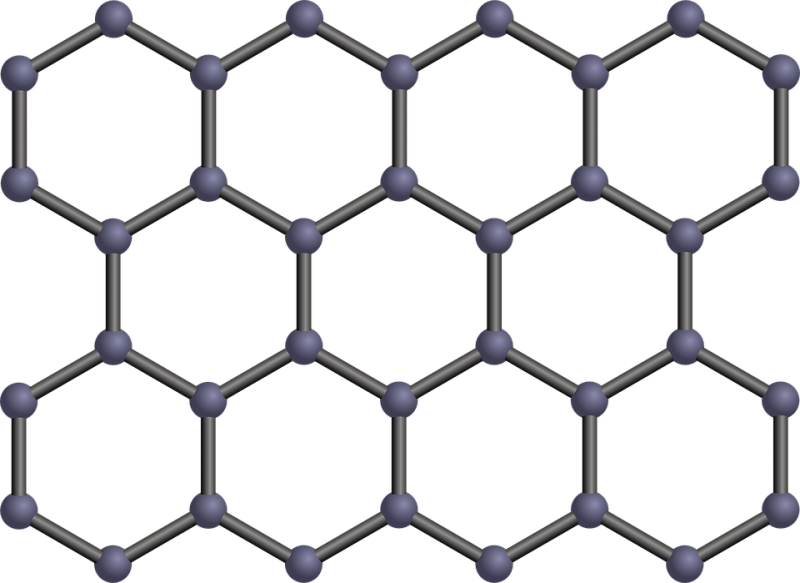

Graphene, image source: Pixabay

Currently, reverse osmosis (RO) desalination technology is used in more than 50% of the world’s desalination plants for the production of fresh water. Within these technologies, thin-film composite (TFC) membranes are the most common material utilized for nanofiltration processes.

However, even though this technology is used across most of our drinking water purification processes, they are still privy to some drawbacks, namely a trade-off between both water flux and salt rejection, chlorine degradation and biofouling- all of which lead to the loss of membrane flux and salt rejection performance.

Biofouling is currently the biggest challenge facing desalination plants. Biofouling in these desalination processes has been linked to microorganisms that attach themselves to the filter membrane, where the membrane(ligand)-organism(receptor) interactions cause the formation of extracellular polymeric substances which increase the adherence of bacteria to the membrane.

To combat this, the Researchers required a material with a large (and smooth) surface area for filtering processes, which also possessed biocidal properties.

Naturally, a derivative of graphene is the obvious choice and the Researchers decided upon graphene oxide (GO) nanosheets that help improve the flux, selectivity and antibacterial properties of TFNC membranes.

The Researchers created the composite by incorporating the graphene oxide nanosheets into a thin polyamide (PA) active layer, in the form of poly tannic acid-functionalized graphene oxide nanosheets (pTA-f-GO).

The layers were produced through interfacial polymerization. The graphene oxide was first functionalized with tannic acid (TA) followed by polyethyleneimine (PEI). The tannic acid groups were found to bind tightly to the graphene oxide surface whilst the PEI groups provided free amine groups which helped to facilitate crosslinking to both the tannic acid groups and the polyamide active layer.

The crosslinking chains were found to interact very strongly with the graphene oxide sheets and tightly integrate them into the nanocomposite matrix.

By incorporating the pTA-f-GO layer into the TFNC membranes, the Researchers achieved a filtration material with a thinner PA layer, lower surface roughness and a higher hydrophobicity. The presence of such properties increased both the membrane water flux by up to 40% and the salt rejection by 8%.

Read full article: AZO Nano

Access article: Nature

Media

Taxonomy

- Membranes

- Polymeric Membranes

- Desalination

- Membrane Technology

- Sustainable Desalination

- Graphene