Trending Tech Company - Onvector

Published on by Water Network Research, Official research team of The Water Network in Technology

Onvector provides patented, leading-edge, directed-energy non-chemical systems for treatment of water and wastewater.

Onvector develops and commercializes innovative technologies at the convergence of energy and water—the two most vital economic inputs.

Our products have the highest levels of performance and the greatest energy efficiency for commercial and industrial facilities. We exploit existing inefficiency gaps in water and wastewater treatment, passing a significant share of cost savings to our customers and partners. Increasing their bottom line drives our top line.

Onvector was spun out of the Nyheim Plasma Institute at Drexel University. We licensed our Ion Pinch technology from Drexel University on a worldwide exclusive basis. During 2014-2015, Onvector provided cost-share support for a research grant at Drexel University funded by the U.S. Department of Energy to develop non-thermal plasma as a platform to treat to produced water from hydraulic fracturing for shale gas and oil.

Onvector’s headquarters are located in King of Prussia, Pennsylvania, USA

Recent Awards

Products

Onvector's products, Ion Pinch and Plasma Vortex, are becoming brand leaders in water purification, wastewater treatment and cooling water scale suppression.

Ion Pinch™

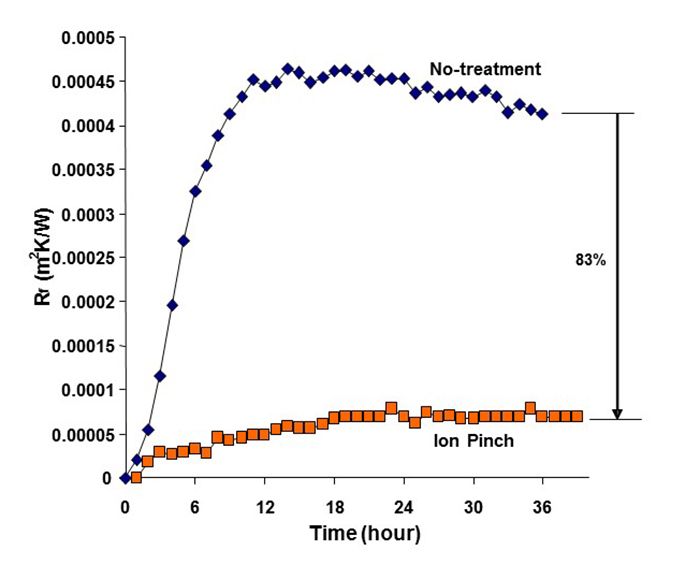

Ion Pinch is a low-voltage AC system for removing scaling minerals from water used in cooling tower applications. Ion Pinch delivers savings in chemical costs, energy costs, and water costs.

Ion Pinch is a low-voltage AC system for removing scaling minerals from water used in cooling tower applications. Ion Pinch delivers savings in chemical costs, energy costs, and water costs.

Ion Pinch is a third-generation water scale suppression system. It is non-chemical water treatment for HVAC & process cooling tower systems. Ion Pinch is installed in-line full flow at cooling loop or on a side-stream loop to suppress mineral fouling, scaling, and biofilm.

How Ion Pinch works

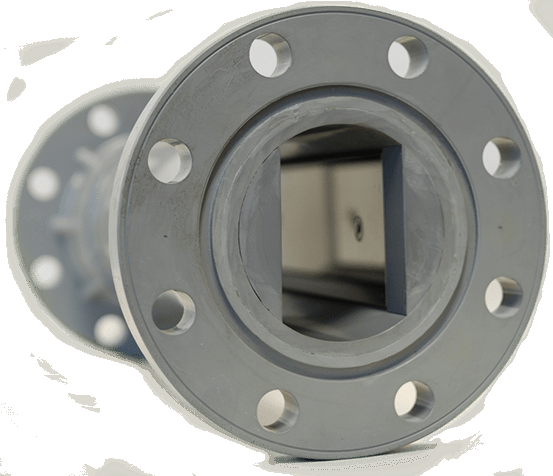

The Ion Pinch is a flanged device installed either inline with a chiller and cooling tower or as a separate sidestream skid with filtration. Its electronic control unit produces an oscillating radio-frequency electric field.

A third-generation descaler and the most powerful device of its kind, Ion Pinch has been proven to modify and soften mineral scale crystals, to protect cooling equipment and prevent unnecessary costs.

As shown using scanning electron microscopes, needle-like aragonite calcium carbonate scale bakes onto chiller and heat exchanger tubes creating major energy losses. Scale formation requires regular cleaning and reduces the operating lifetime of equipment.

Ion Pinch forms soft hexagonal-shaped calcite scale particles in water instead of on the equipment to protect chillers and heat exchangers. These particles compete with tube surfaces for more minerals and grow in size. They wash away by the normal flow of cooling water and are easily removable by filtration.

The patented method applies electric fields directly to water, unlike the indirect applications of first and second-generation magnets and coils. Because our electric fields are applied directly, the Ion Pinch has no maximum frequency or field strength, increasing the descaling performance of the Ion Pinch. This key difference makes Ion Pinch the most powerful and efficient device of its kind.

Combined with filtration, the Ion Pinch behaves as a non-chemical softener, creating soft particles and removing them generating additional cost savings by reduced water make-up and discharge expenses.

Plasma Vortex™

Plasma Vortex is a high-voltage plasma device for sterilization and oxidation of industrial wastewater. An alternative to incineration for the highly contaminated streams, Plasma Vortex creates “lightning” in water without the use of sprays, bubbles or moving parts.

Plasma Vortex is a high-voltage plasma device for sterilization and oxidation of industrial wastewater. An alternative to incineration for the highly contaminated streams, Plasma Vortex creates “lightning” in water without the use of sprays, bubbles or moving parts.

Plasma Vortex is a high-voltage plasma device for sterilization and oxidation of industrial wastewater. An alternative to incineration for the most highly contaminant streams, Plasma Vortex is the only technology that delivers “lightning” without the use of sprays, bubbles or moving parts.

How Plasma Vortex Works

Plasma Vortex is literally ‘lightning in a bottle.’ Plasma Vortex is an advanced oxidation process in the same category as ozone and UV but much more efficient because it generates multiple reactive species not just one. This high-voltage plasma system for manufacturing wastewater delivers hydroxyl radicals, UV, ozone, H2O2, singlet oxygen, free electrons, and focal areas of high temperature.

Plasma Vortex serves as an alternative to incineration for manufacturing wastewater from pharmaceuticals, chemicals, petrochemicals, oil & gas, and food & beverage industries.

Media

Taxonomy

- Oil & Gas

- Water

- Treatment

- Industrial Wastewater Treatment

- Waste Water Treatments

- Energy

- Fracking

1 Comment

-

I am a firm believer in all vortex technology. from rocket engine designs, toilet flushing vortex systems, data compression for computer memory storage, and now we use this basic technology to help understand tornados and hurricanes. As much of being a fan that I am I must be logical as to the limitations of this technology. All natural vortexes are beneficial. Man made vortex items are always less efficient than natures. Aside from the obvious. There appears to be a worldwide movement to be aware of and be part of a circular economy. Many ways of doing this of course. But carbon "police" use a term called "Carbon foot print". Hang in there a moment. Onvector can fix their own problem if it is pointed out to them. A rough calculation is for every one unit of cleaned item you require 10 units of carbon "foot print" to accomplish your mechanical solution. Most at best are shooting to be carbon neutral. I just can not see the logic of improving the bottom line of an industry that charges monies for a free natural resource at the expense of nature and its inhabitants. There are several non mechanical and non chemical items that do this natural biological function at a fraction of the cost. This type of technology would be most useful in the transition from centralized water and waste water purification to a decentralized construct. This would eliminate massive infrastructure and their costs and have emergency water supply on location in case of power outage and water contamination. Puerto Rico most certainly could have benefited from this. Hard to knock out the electrical grid when there is no grid. Home water, wastewater processing, electrical collection and storage, food and other items for long term storage. Think of the suffering that would be prevented. A big difference in survive and thrive. Think about it.