Upgrading DWTP Operations with the QbD1200 TOC Analyzer

Published on by Water Network Research, Official research team of The Water Network in Technology

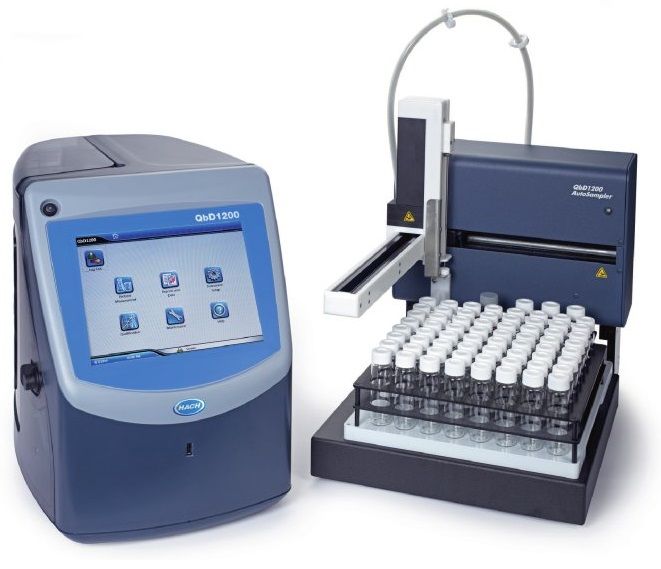

The Hach QbD1200 TOC Analyzer is an accurate, reliable, and easy to use instrument for analyzing low range Total Organic Carbon (TOC) samples.

The following article presents Hach's Case Study: Upgrading DWTP Operations in Kansas with the QbD1200 TOC Analyzer.

Introduction

For drinking water treatment plants (DWTPs), the EPA’s Disinfection Byproduct Rule (DBP) is a way of life. This standard ensures water quality in the distribution system by enforcing the removal of organic matter from water, thus dictating treatment plant operations. Unfortunately, for many facilities the equipment and operations haven’t evolved with the regulation mandates, leaving facilities in a tough spot.

With the Disinfection Byproduct Rule being over 10 years old, accurate and trustworthy total organic carbon (TOC) measurement should be standard for DWTPs at this point. However, that’s not always the case. For a DWTP in Douglas County, KS, its challenges with accurate TOC measurement and testing, along with expensive calibrations and extended downtime with its prior TOC analyzer led it to trialing the Hach QbD1200 TOC Analyzer

With the Disinfection Byproduct Rule being over 10 years old, accurate and trustworthy total organic carbon (TOC) measurement should be standard for DWTPs at this point. However, that’s not always the case. For a DWTP in Douglas County, KS, its challenges with accurate TOC measurement and testing, along with expensive calibrations and extended downtime with its prior TOC analyzer led it to trialing the Hach QbD1200 TOC Analyzer

Plant Profile & Challenges

The utility, owned by Douglas County Rural Water District 3 in Kansas, operates two DWTPs and 280 miles of distribution network. It processes approximately 3 MGD with a three-man team, putting efficiency and ease-of-use at a premium. To meet regulatory requirements, this facility is responsible for removing a certain percentage of TOC during the treatment process.

The DWTP evaluates many common parameters such as turbidity and TOC. However, because the plant is located at the shallow end of a lake, turbidity from natural organic material (NOM) can be scarce—particularly in the winter months. This puts extra importance on TOC measurements, as the plant reports the percent of TOC removal to the state. Without precise data, the utility risks failing to remove enough carbon to meet regulatory requirements.

Like many drinking water facilities, this plant focuses on:

- Meeting percent TOC removal regulations

- Optimizing coagulant treatment while avoiding DBPs in effluent

- Maintaining equipment and minimizing downtime.

Before installing the Hach QbD1200, the DWTP measured TOC with a membrane-based TOC analyzer, or membrane conductometric (MC) analyzer. The plant faced several problems in regard to its TOC equipment. First, the equipment’s readings didn’t align with the state-certified third-party lab that the facility sends samples to.

It’s a slippery slope. The DWTP couldn’t trust its measurements, so forecasting coagulant doses was like predicting the weather. To stay within compliance, the DWTP overtreated with coagulant to leave a buffer in case its readings weren’t the same as the certified lab’s. The facility was doing everything possible to meet regulations, but devoting a significant amount of operating expense to coagulant.

Unfortunately, this predicament can lead a DWTP to expending time and money on damage control when samples fall out of compliance. “If I don’t make TOC regulations once, it’s about $15,000; that’s the cost for a mailing to the public,” says Lucas. However, if a treatment plant can trust its TOC measurements, an opportunity to optimize chemical treatments surfaces—offering cost savings, lowering total cost of ownership, and delivering higher water quality.

In addition to challenges with TOC measurement, service on the MC equipment created operation and budget issues. “You were at their mercy if it broke,” says Lucas, “We might be out thousands of dollars and out of commission weeks. We can’t afford to be out weeks; we can hardly afford to be out days.”

Lastly, the MC unit does not work with any reagents other than the manufacturer’s, giving the DWTP no options for cost savings on purchasing other reagents or making its own. The DWTP approximates $5,000 for maintenance and reagents, with increasing costs to replace equipment.

Solution

Recently, the MC provider dropped support for the facility’s TOC analyzer, leaving the DWTP in a position to switch to equipment. “We knew Hach was coming out with a new TOC analyzer. We went to see the analyzer at a convention in Wichita,” says Lucas. “We got our hands on it and were put on the list for a trial. At the end of the conference the trial unit was waiting for me. It was outstanding.”

Recently, the MC provider dropped support for the facility’s TOC analyzer, leaving the DWTP in a position to switch to equipment. “We knew Hach was coming out with a new TOC analyzer. We went to see the analyzer at a convention in Wichita,” says Lucas. “We got our hands on it and were put on the list for a trial. At the end of the conference the trial unit was waiting for me. It was outstanding.”

The QbD1200 offers reliable TOC measurements, giving plants the data needed to optimize coagulant treatment. “What we saw during the Hach trial period: We took samples to the City of Lawrence certified lab, and Hach results mirrored Lawrence’s,” says Lucas. With newfound trust in the measurements, Lucas’s team can analyze and optimize coagulant dosing, giving them control over processes and cutting down on unnecessary chemical treatments.

Lucas says: “If we’re running new polymer trials, we’ll run 60 - 70 sets per day so we can change our process…If I can change a coagulant and save ten cents per pound—which is about one dollar per gallon—if I buy 45,000 pounds annually, that’s pretty good cost savings there. We’re only a 3 MGD facility. Other utilities need to look at this. It will do more than just keep you in TOC [compliance].”

Using the QbD1200, the DWTP optimized its water treatment process and achieved the following:

Using the QbD1200, the DWTP optimized its water treatment process and achieved the following:

Reduced polymer feed rate by 40%, leading to annual cost savings of $12,400

Reduced ferric chloride dosing by 25%, leading to cost savings of $2,200

Saved $14,250 thanks to making reagents in-house and Hach’s maintenance program.

With only three operators at the utility, the DWTP paired the QbD1200 with a Hach autosampler to run high volumes of tests. This allows the DWTP to set up the sampler and run tests without manually managing the process. “We can set the system up, punch a button, and see the results,” says Lucas.

Beyond the cost savings and treatment optimizations, the Douglas County DWTP values the QbD1200’s ease-of-use and Hach Field Support. These two things give the utility the ability to measure TOC reliably with little downtime, frustration, and costs. “It’s easy to use. I could probably bring a 10 or 12-year-old kid in and have him run it. It’s all color-coded, and you can make your own reagents,” says Lucas. “We can do real-time data; make real time decisions. You can’t put a cost on that. It’s so much more accurate.”

Conclusion

Accurate measurement, painless operation, fast calibration, and reagent flexibility all contribute to this utility’s improving operations. With the help of the QbD1200, the plant forecasts annual savings of $30,000 to $60,000 based on improved processes for TOC removal as well as optimizations for chemical treatment selection, quantity, and frequency. That’s what Hach equipment is all about: easy-to-use instruments with unparalleled total cost of ownership.

Media

Taxonomy

- Standards & Quality

- Technology

- Water Quality

- Analysis & Visualization

- Water Quality Monitoring

- Data & Analysis