Using Electro-induced Treatment to Clean Landfill Leachate in Rural China

Published on by OriginClear Inc. in Technology

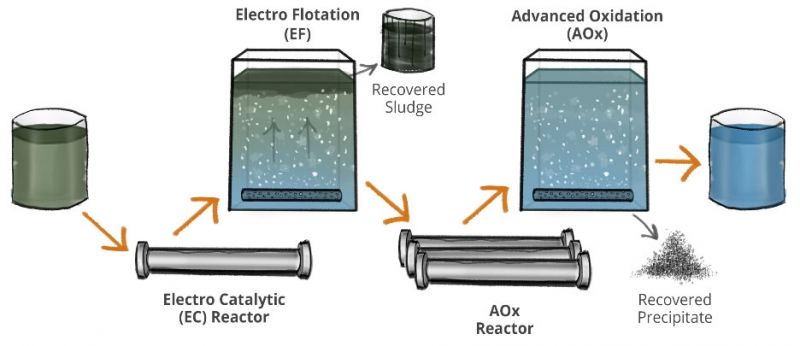

Electro Water Separation with Advanced Oxidation is a sequential combination of electrically induced gas flotation (EWS) and advanced oxidation ( AOx ).

Landfill leachate is one of the most notoriously difficult wastewaters to clean. A result of rain or ground water that flows through the municipal and industrial wastes in landfills, this murky black liquid is a highly contaminated and complex industrial effluent filled with volatile organic and inorganic chemicals, heavy metals and pathogens.

When leachate is not managed properly, potentially toxic pollutants could contaminate soil, groundwater and surface water surrounding the landfill and lead to a health risk for local communities. For example, communities in Ghana are facing deadly waterborne diseases because their local landfill is the world’s largest dumping ground for electronic waste.

Issues like this exist worldwide – as economic development expands, so will trash creation. Global landfill issues will only become more extreme in the coming years.

Many governments are taking note of the hazardous effects that occur when landfill leachate is introduced to our environment, and are updating discharge standards to promote the adoption of modern wastewater treatment technologies in landfill management.

This is especially true in China, where the EPA has already introduced new water discharge standards. As the demand for responsible treatment of landfill leachate grows, the wastewater industry finds itself hungry for an efficient, reliable and cost-effective way to clean up this dirty and extremely hazardous water.

Current technologies to clean landfill leachate rely on biological processes. While they are extremely effective at cleaning up low to medium organic contamination loads, existing processes lack the long-term operational and economic efficiency needed for tougher jobs like landfill leachate.

Electro Water Separation with Advanced Oxidation (EWS:AOx™), which OriginClear developed in the United States, is a sequential combination of electrically induced gas flotation (EWS) and advanced oxidation (AOx). AOx relies on in-situ generated powerful oxidants, resulting from known chemical reactions occurring when the wastewater stream contacts a series of specifically designed electrodes.

It is a fast, versatile, low maintenance process using electricity combined with a relatively small, optimizing quantity of simple chemical additives, such as sodium hydroxide (NaOH), whose component atoms are part of, and vanish with, process reactions. Landfill managers are finding new opportunities for their wastewater with the EWS:AOx treatment system.

Cleaning up landfill leachate in rural China

In China, OriginClear put its landfill leachate treatment process to the test at a demonstration site in a rural northern China city landfill. The operator of this site required a solution beyond traditional treatment methods like disk tubular reverse osmosis membranes, which require frequent de-clogging due to the extreme contamination present in landfill leachate and in turn drive up onsite maintenance costs.

The goal for this initial demonstration was to use OriginClear’s EWS system to reduce chemical oxygen demand (COD) from 10,000mg/l to 100mg/l and Ammonia (NH4) from mid-300ppm to 8ppm. This pilot project was also an opportunity for OriginClear to show proof of concept of technology in a flow-through scenario and demonstrate effective treatment in real time.

Methods

OriginClear set up a 7-step treatment process to maximize contaminant removal (Fig. 1). The flow rate was set at approximately 12 liters per minute to match the full tank capacity of the AOx module and optimize efficiency.

Prior to entering any treatment system, FeSO47H2O (Iron(II) Sulfate Heptahydrate) was added to the influent water in the holding tank to reduce biological oxygen demand (BOD) and allow contaminants to clump together more easily.

NaOH was also added to the holding tank to raise the pH to 10 and further assist flocculation. After adding NaOH to the holding tank, treatment operators visually identified extreme flocculation and a black product coming out of the influent wastewater solution.

Once pretreated with necessary additives, the influent water entered the A25 EWS flotation unit. In this step, suspended solids are separated and clumped together using anodic reactor tubes. Visual inspection showed that at this stage a large mat of grey suspended solids floated atop the EWS unit. This sludge was then harvested for offsite disposal.

Once the electroflotation was complete, the wastewater flowed through an ultrafiltration (UF) membrane to improve clarity.

The influent water was then sent through an A12 Advanced Oxidation unit with a pH of 8.7. In this step, specifically designed electrodes oxidize hard-to-remove dissolved contaminants in the wastewater using predictable chemical reactions. Hydrogen chloride (HCl) was also added to the wastewater stream in this step to bring the pH of the solution down to 6.5.

Finally, the wastewater went through more traditional treatment processes -- an ultrafiltration (UF) membrane to remove any trace contaminants, and a reverse osmosis (R/O) system for final polishing. By treating the wastewater with the EWS:AOx system before introducing it to the UF and R/O technologies, the bulk of the contaminants were removed up front and thus the chance of clogging the UF and R/O stages decreased.

Figure 1 (see attachment): A flowchart of the methods used in OriginClear's landfill leachate project at a northern China landfill.

Lab results EWS:AOx output prior to RO:

Metric (mg/l) | Raw water | Post-EWS | % drop |

COD | 10,239 | 2,583 | 75 |

Ammonia | 2,036 | 610 | 70 |

Sulfur | 2,078 | 713 | 65 |

Figure 2: Lab results prior to RO treatment show a significant decrease in COD, Ammonia and Sulfur.

Results

After treatment with the EWS:AOx system, COD fell by 75 percent, Ammonia was reduced by 70 percent and Sulfur decreased by 65 percent (Fig. 2). The black and murky wastewater turned to a light brown color following EWS:AOx treatment, and was crystal clear after passing through the final RO membrane. Onsite testing showed final ammonia levels at 8ppm and a COD under 100.

Limitations

One of the main challenges when treating landfill leachate is the variability in wastewater. Contaminants are dependent upon the type of trash being placed into a landfill, the surrounding environment and the age of the landfill. For example, a landfill in rural China would look quite different from one located in New York City. The more specialized the treatment equipment can be, the more effectively it will remove contaminants.

The machines used in this initial pilot demonstration were not specialized for wastewater treatment and further customization of both equipment and procedure could have led to more effective contaminant removal. This project used converted algae harvesting equipment, which is normally used for a very specific organic load, namely, mostly TSS at maximum levels of 3,000 mg/l.

Also, due to construction constraints, the residence time in AOx module was limited to 15 minutes, which, while being quite sufficient for moderately contaminated effluents, is in most cases below the usually required time for COD/BOD levels above a few thousand ppm. Despite these limitations, the EWS:AOx modules chain has clearly demonstrated its ability to abate the major contamination factors that can be found in landfill leachate, and has potential to bring effective treatment solutions to this challenging market.

Cost Assessment

Due to the high variability in wastewater composition, treatment methods and local discharge requirements, little information is available on landfill treatment costs. Interviews with end users in China suggest that existing leachate treatment costs roughly $10 - $15 per m3 of wastewater, and a cost analysis of EWS:AOx suggests that the total cost of OriginClear’s treatment ranges from $1.27 - $7.83 per m3 of wastewater.

The major operating cost factors of EWS:AOx are electricity and the appropriately optimized pH adjustment and coagulation enhancement additives to prepare the wastewater for treatment. As EWS:AOx is applied to tougher wastewater applications like landfill leachate, operating costs will increase as a result of longer system running time and the need for more upfront additives.

Conclusion

EWS:AOx™ shows promise in remediating not just leachate, but any industrial wastewater with a high contaminant load. Electro-induced flotation and Advanced Oxidation demonstrated its efficiency not only as a stand-alone system, but also for reducing the load on polishing systems such as membranes or Reverse Osmosis units. Separate tests point to a significant reduction in membrane fouling.

Construction engineering is currently exploring options for retrofitting existing flotation units, as well as responsive residence time and energy input combinations to enable AOx to adapt to contamination load variations over long periods of time. Additional studies will also address the optimization paths for enabling synergistic interactions between EWS:AOx and complementary modules, to efficiently address the removal of TDS or other specific contaminants, that may only be partially removed by EWS:AOx.

Media

Taxonomy

- Electrocoagulation

- Polluted Water Oxidation

- Wastewater Treatment

1 Comment

-

The landfill leakage treatment is one of challenges for engineers, due to variable wastewater composition. The described OriginClear process and 7 step system, applied in China is interesting and given information is very useful.

It would be interesting to know:

What is the maximum flow capacity per unit for Electro Water Separation with Advanced Oxidation (EWS: AOx™) which you have developed for leakage treatment?

Where is it applied so far and do you have leachate treatment plants in Europe?

What is the average amount of energy consumed in kW per m3 of treated water?