Vacuum Multi Effect Membrane Distillation (VMEMD)

Published on by Water Network Research, Official research team of The Water Network in Technology

The innovative VMEMD Process by EvCon Technology - The UPWaterSystem is based on an absolutely new and patented process: the Vacuum Multi Effect Membrane Distillation - VMEMD.

This is a thermal separation method that takes place in vacuum and uses the introduced heat multiplicate for evaporation. This way not only water can be obtained in pure and even ultra pure quality: This method of water desalination requires in many cases significantly less energy than alternatives and is much more efficient – and also less expensive – than ever possible before.

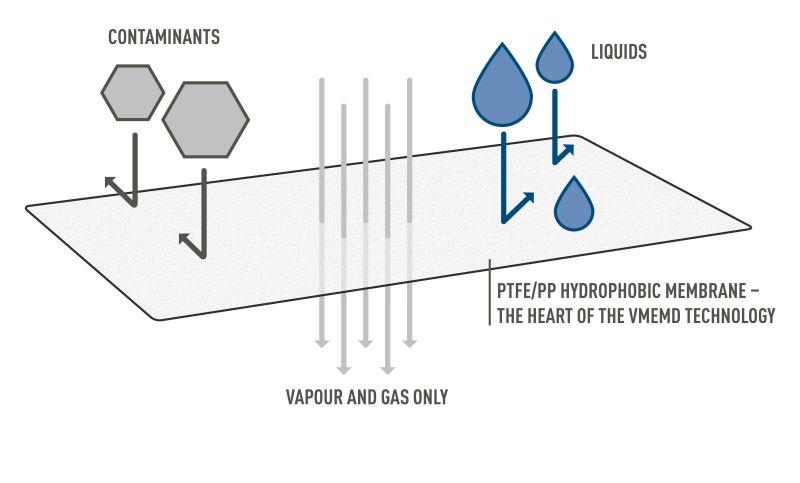

The fine pores of the hydrophobic membrane are only permeable for pure water steam. Water and its volatile substance content are rejected – even the finest drops. Source: EvCon Water

The VMEMD method, the modular construction of the UPWaterSystems and the use of corrosion-resistant polymers will open new perspectives wherever availability of pure water of the highest quality is wanted, from sea water desalination to use in industry and agriculture.

Innovation modeled by nature

Why is rain fresh water when 97.5 % of the Earth’s water contains salt?

School children know: Water and salt are separated during evaporation. Pure water vapor rises in the air, condenses in clouds and gathers to drops until it falls as drinkable rain.

The innovative Vacuum Multi Effect Membrane Distillation (VMEMD) is modeled on this ideal from nature. In addition, it uses a hydrophobic membrane that ensures the purity, compactness and efficiency of the process. The result is a groundbreaking method for thermal water treatment.

Hydrophobic membrane: Permeable only for water steam, not for liquid water.

The heart of the VMEMD method is therefore interaction between the hydrophobic, steam-permeable membrane made of PTFE (Polytetrafluoroethylene) and a foil made of PP (Polypropylen). The membrane holds back liquid and its volatile content. Only water steam can pass through – and condenses in the next effect on a very thin and resilient foil. By this means, no drops are carried along during evaporation. The result is a very pure high-quality distillate.

Media

Taxonomy

- Ultrafiltration

- Filtration

- Filtration

- Desalination

- Membrane Technology

- Membrane Filtration

- Filtration

- Sustainable Desalination

- Desalination

- Membrane distillation