What Plants Can Teach us About Oil Spill Clean-up and Microfluidics

Published on by Water Network Research, Official research team of The Water Network in Technology

A new USC study takes a cue from leaf structure to fabricate material that can separate oil and water, which could lead to safer and more efficient oil spill clean-up methods.

In addition, the material is capable of “microdroplet manipulation,” or the transfer of miniature volumes of liquid. Droplet-based microfluidics is a tool used in various applications like cell cultures, chemical synthesis and DNA sequencing.

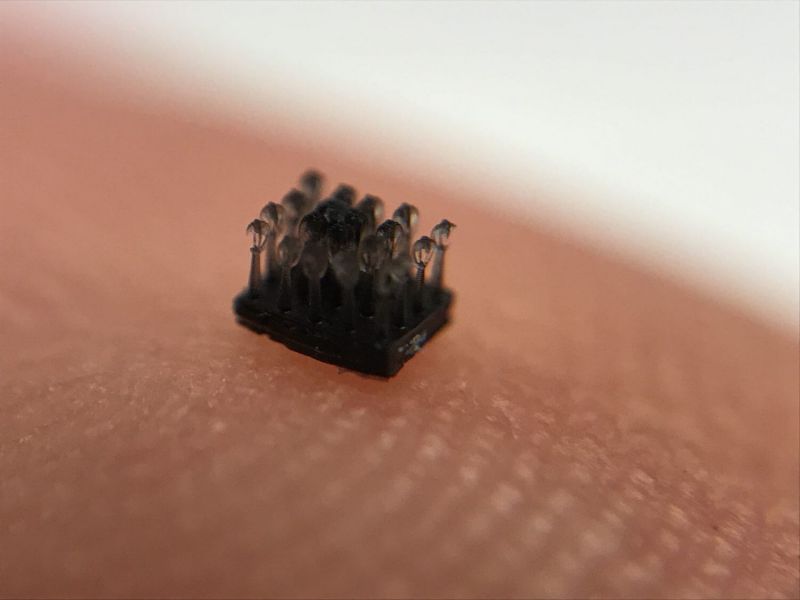

3-D PRINTED PROTOTYPE OF SUPER-HYDROPHOBIC “EGG-BEATER” STRUCTURE. PHOTO CREDIT/YANG YANG, VIA: USV VITERBI

Using 3-D printing, Associate Professor Yong Chen and his research team at the Daniel J. Epstein School of Industrial and Systems Engineering have successfully mimicked a biological phenomenon in plant leaves called “Salvinia effect.” Their study focuses on a floating fern native to South America called Salvinia molesta. The unique leaves are super-hydrophobic, meaning “water-fearing” and retain a surrounding air pocket when submerged in water due to the presence of water-resistant hairs.

“I think the reason the plant’s surface is super-hydrophobic is because it lives on the water and requires air to survive,” Yang Yang, a postdoctoral researcher on Chen’s team, said. “If it weren’t for the long-term evolution of this plant, the plant could be submerged in water and would die.”

Water-repellent structure

On a microscopic level, the leaf hairs align in a structure resembling an egg-beater, or cooking whisk. Chen explains that Salvinia’s leaf surface is comprised of this so-called “egg-beater” structure that is super-hydrophobic.

Using a method called immersed surface accumulation 3-D printing (ISA-3D printing), the research team successfully created the egg-beater microstructure in samples made from plastic and carbon nanotubes. Chen explains that the method allowed the team to demonstrate the fabrication of a material with both super-hydrophobic and olephilic (oil-absorbing) properties that, when combined, generate capillary forces capable of highly efficient oil and water separation.

“We tried to create one functional surface texture that would be able to separate oil from water,” Chen said. “Basically, we modified the surface of the materials by using a 3-D printing approach that helped us achieve some interesting surface properties.”

The team has 3-D printed a prototype, citing a growing demand for materials that can separate oil and water mixtures efficiently in vast bodies of water. Eventually, they hope the technology can be applied to manufacture materials in large scale to accommodate massive oil spills in the ocean. Current methods require tremendous energy in the form of an electric field or mechanically-applied pressure.

Read full article: USC Viterbi

Media

Taxonomy

- Water Pollution

- Treatment

- Oil Water Separation

- Biological Treatment

- Pollution

- water treatment

- Pollution

- Printers

- 3D Modelling