Why Water Matters- one of our top priorities

Published on by Water Network Research, Official research team of The Water Network in Business

To the World:

We recognize access to clean and safe water as a fundamental human right. Around 2 billion people do not have access to clean and safe drinking water, and approximately 3.5 billion people – 46% of the world's population – lack adequate sanitation services. 1 Climate change and other factors may increase the burden on both water supply and quality. Some communities struggle with water scarcity, and ecosystems may degrade. As a result, there is a strong imperative for the business community to deploy expertise and resources to address these issues.

Approach

Water stewardship has long been one of PepsiCo’s top priorities. We have a vision to become net water positive by 2030— an ambition borne from our longstanding belief that access to water is a human right. Additionally, water is critical to our business, the communities where our products are made and the natural environment.

In pursuit of this, we have adopted an approach to watershed management that includes efforts to:

- Improve water-use efficiency in manufacturing facilities — prioritizing those in high water-risk (HWR) areas;

- Replenish water and improve the health of the local watersheds that are at highest water risk where we source crops and where we operate; and

- Increase safe water access for communities that face water insecurity, including scarcity and unsafe water sources.

The foundation of our net water positive vision is an effort to work towards improving water resources in high water-risk areas where we operate. We work with community stakeholders to understand water challenges at a local level and support collaborative solutions that aim to address the specific needs of the watershed and the communities that depend on it. Progress toward this vision relies not only on our own operations, but on water stewardship at franchise bottler manufacturing facilities.

Goals

By the end of 2025, we aim to:

- Achieve 100% water replenishment at company-owned facilities designated in high water-risk areas; 2 and

- Continue to adopt the Alliance for Water Stewardship (AWS) Standard in high water-risk PepsiCo-owned manufacturing facilities, as a vehicle for water advocacy.

By 2030, we aim to:

- Reach average water-use efficiency ratios of 1.4 liters/liter of production in beverages sites and 1.7 liters/kilogram of production in convenient foods sites for 100% of high water-risk PepsiCo and franchise bottler manufacturing facilities; 3

- Replenish back into the local watershed 100% of the water we use in high water-risk PepsiCo and franchise bottler manufacturing facilities ; 4 and

- Reach 100 million people with safe water access . 5

We believe long-term transformation requires agility to identify what's working, what isn't, and adjust our approach to focus our impact on the locations with the most significant risks. We regularly review our sustainability goals and initiatives and consider changes that are from time to time warranted, including in the context of new developments, such as business growth, necessary investments relating to our initiatives, as well as external developments.

pep+ in context: Water

How we're working toward our vision of becoming net water positive:

Operations

Improving water efficiency

PepsiCo supports the principles of circular water within our company-owned high water-risk manufacturing operations and high water-risk franchise bottler manufacturing. This means we focus on minimizing our freshwater dependency by identifying opportunities to treat and reuse processed water at these facilities.

We assess operational water-use efficiency against our peers based on publicly-available information, peer company commitments and information shared with us through industry groups. This benchmarking helps inform our water agenda, including the goals we set.

In our own operations, we aim to drive efficiencies through initiatives such as our Resource Conservation (ReCon) program, which identifies operational efficiency best practices at the plant level and shares them across PepsiCo, franchise bottler and contract manufacturer locations. We are also developing low-water manufacturing processes and investing in new technologies that allow us to safely recover and reuse water.

Water sustainability is integrated across our business, including in the design of line expansions, validation of new water reuse solutions, product design and capital approval processes. Through these and more, we expect to continue to invest significantly to support our water strategy.

Water replenishment

Given the risks facing good quality fresh water and the importance of water availability to our business, we aim to replenish 100% of the water we use in high risk watersheds. In other words, we aim to help restore and protect freshwater ecosystems by putting back the same amount of water that we take from local watersheds. We continue to measure progress against both our original 2025 and extended 2030 goals. The goals, while similar, differ as follows:

- 2025: 100% water replenishment at company-owned facilities designated in high water-risk areas (prior to the re-assessment conducted in 2022); 2

- 2030: 100% water replenishment at company-owned facilities and franchise bottler manufacturing facilities in high water-risk areas. 4

To do that, we’re working with partners to deploy a range of initiatives that aim to restore the health of high-risk watersheds. The most common types of projects are those that seek to:

- Conserve and restore land to reduce impacts on watershed from excessive water and nutrient runoff and increase groundwater infiltration;

- Increase water supply reliability through water-use efficiency improvements; and/or

- Restore and protect aquatic habitats and ecosystems through wetland protection or restoration.

Each watershed is unique, so we work with local partners to identify replenishment tactics that are informed by the unique challenges and local conditions. For example, we are working with local partners near the plant where we produce Alvalle Gazpacho to replenish the Segura River in Andalusia, Spain. This work includes removing water-intensive invasive species along the river and replanting the area with native plants adapted to the water availability of the region. The native plants help to increase water availability in the river, protect against flooding and preserve other native flora, contributing to the area’s ecosystem and biodiversity.

We know that collective action is needed to address shared water challenges. That’s why we include franchise bottler manufacturing facilities in high water-risk areas in our water efficiency and replenishment ambitions. We are working together to share best practices and source performance data to track and improve progress towards our net water positive vision.

Advocacy for improved water security

While we can make a positive impact in water stewardship through action within our value chain, we also have opportunities to help mitigate water insecurity more broadly, through advocacy for improved water governance and through increased collective action.

We support existing collaborative efforts to address water risk and mitigate water insecurity and also seek out new opportunities for collaborations. We do this by advocating for the adoption of smart water policies and regulations; by sharing information and best practices with local stakeholders; and by providing public education and training for communities. In 2018, we joined the Alliance for Water Stewardship and aim to adopt the AWS Standard at all high water-risk company-owned facilities by the end of 2025 , using it as a vehicle for advocacy and to help ensure that freshwater resources in high water-risk locations are available for all water stakeholders. AWS adoption is led by cross-functional teams of PepsiCo associates who have come together to identify local water risks and evaluate opportunities for the facilities to implement good water stewardship practices.

Community

Access to clean and safe water is a fundamental human right, and with billions of people lacking access, it is a problem of global importance. Water insecurity puts communities at risk, increases negative health outcomes, decreases food availability, increases costs of basic goods and services and, in the worst cases, can drive people from their homes.

PepsiCo and the PepsiCo Foundation partner with experts aiming to close the gap in safe water access programs, implementing projects primarily in Latin America, Asia, the Middle East and Africa. These efforts are designed to help improve water security, including:

- Building sanitation facilities and community water systems,

- Providing loans to families to build water infrastructure in their homes,

- Supporting local water entrepreneurs,

- Installing community water access points and

- Helping to rehabilitate natural springs.

We launched an open-access online course on water in 2023 to share the knowledge from experts and partners and help educate people within and outside the company on water issues. Courses include The Water Cycle, Water Security and Stewardship and Water Governance and Economics; each is available to audit for free.

Agriculture

Beyond our direct, operational water-use, we aim to work with farmers and NGOs to improve agricultural water-use efficiency as part of our pep+ regenerative agriculture ambitions. Regenerative agricultural practices include farming in ways that improve watershed health. For many crops, this means improving the efficiency of irrigation.

To improve irrigation practices and embed other water stewardship practices, we identify opportunities in high water risk locations, develop phased action plans, aim to ensure farmers have the correct equipment, and train them to execute against water goals. By the end of 2024, 55 demonstration farms were testing and sharing best practices around the world, many of which feature water-use efficiency best practices or demonstrable improvements in water quality. These farms provide an opportunity to engage large numbers of farmers in hands-on learning and understanding of innovation.

A key aspect of our approach is helping farmers transition to more water-efficient irrigation equipment, such as drip irrigation. Our partnership with N-Drip aims to help farmers in our supply chain adopt high-efficiency irrigation technology to deliver significant water and energy savings compared to conventional systems. N-Drip’s gravity-powered technology combines the water-saving benefits of high-pressure drip irrigation with lower energy, operating and maintenance demands.

As we continue to improve water-use efficiency in areas where we directly source our crops, we identify the specific needs of high water-risk locations and create action plans that support farmers with the relevant training, equipment and resources they need to meet water goals. We recognize that water stress is experienced not only by farmers supplying PepsiCo but also by other farmers working in that watershed. Without comprehensive action to implement more sustainable practices across the board, local communities and the natural environment will continue to be at risk. For this reason, we’ve expanded our work to include broader watershed health actions in two of the most at-risk sourcing regions in the world: Caborca, Mexico and Uttar Pradesh, India.

For more on our efforts to spread the adoption of sustainable agricultural practices, see Agriculture.

Governance

Our global approach to water stewardship is led by a team of water experts in PepsiCo’s Global Sustainability Office. They, in turn, collaborate with our operating segment teams and external partners to execute our strategy and work toward achieving our goals. PepsiCo’s water strategy applies to the entire organization, including all companies, entities or groups over which PepsiCo exercises operational control. Portions of our water strategy, including operational water-use efficiency and replenishment, also apply to franchise bottlers.

The Board plays an essential role in determining PepsiCo’s strategic priorities and considers sustainability issues (e.g., water stewardship) as an integral part of its business oversight. To this end, the Board established a Sustainability and Public Policy Committee to assist the Board in providing more focused oversight of key sustainability, inclusion and public policy matters. One of the primary responsibilities of the Committee is to review PepsiCo’s key sustainability programs and related goals and monitor the Company’s progress toward achieving those goals, including progress against its water goals.

The PepsiCo Executive Committee (PEC), made up of the Chairman & CEO, the CFO, operating segment CEOs and functional heads, meets quarterly to review progress against goals, progress against broader environmental risk mitigation and to ensure that we are adapting our sustainability strategy to scientific developments, changes in stakeholder expectations and marketplace conditions. In addition, the PepsiCo Sustainability Committee, a sub-committee of the PEC, takes further responsibility for sustainability matters and meets on a monthly basis to discuss strategy and progress.

Assessing water risk

Through our Enterprise Risk Management process, we identify and assess water-related risks within our direct operations and other stages of our value chain twice per year. Supplementing that process, we also conduct an in-depth global water risk assessment of all company-owned operations on a rolling three-year cycle, most recently in 2025 — though 2024 progress is reported based on our prior assessments. Our 2025 assessment included third-party manufacturing operations, which had previously been assessed asynchronously from our own-operation assessment. For both, we have partnered with a specialized environmental consultancy to develop a robust water risk assessment process that leverages multiple data sets and local insights. This process is designed to provide PepsiCo with a holistic view of current and future water-related risks in our global manufacturing locations and inform the action we take.

Tools used as assessment inputs can include the World Resources Institute’s (WRI) Aqueduct tool, the World Wide Fund for Nature (WWF) Water Risk Filter tool, local site risk assessment surveys and third-party independent expert experience and knowledge operating within the watersheds. This helps us to determine and quantify the level of physical (quantity and quality), regulatory and reputational water risk.

The outcome of our operational water risk assessment informs which locations are designated as high risk and allows us to focus our efforts and resources where it matters most.

Progress

Our 2024 ESG reporting suite, which includes this ESG Topics A-Z page and our ESG Summary, represents the first time we are reporting progress against our evolved water goals.

By innovating and scaling solutions globally, we met two of our 2025 water targets (to achieve a 25% improvement in water-use efficiency in high-risk areas and to improve water-use efficiency by 15% as part of our broader goal to advocate for and contribute to a measurable improvement in the health of high water-risk watersheds where we directly source our crops) two years early in 2023. In 2024, we continued this momentum, expanding and refining these solutions to deepen impact.

Improving water-use efficiency in our direct operations

At the end of 2024, PepsiCo had 102 out of 285 total company-owned manufacturing sites that were high water-risk manufacturing locations as defined by our global water risk assessment process. These locations account for 36% of our company-owned manufacturing facilities, with high water-risk locations accounting for 30% of our company-owned production volume. To track our operational water-use efficiency goal, we measure both water withdrawal (the total amount of water that we remove from a water source) in high water-risk areas and non-high water-risk areas as well as the volume of product produced. In 2024, we withdrew approximately 74 million cubic meters of water across all company-owned operations — 24% from regions of high water-risk. Water consumption (the amount we withdraw that is not replenished back into its source) was approximately 24 million cubic meters of water — 25% from regions of high water-risk.

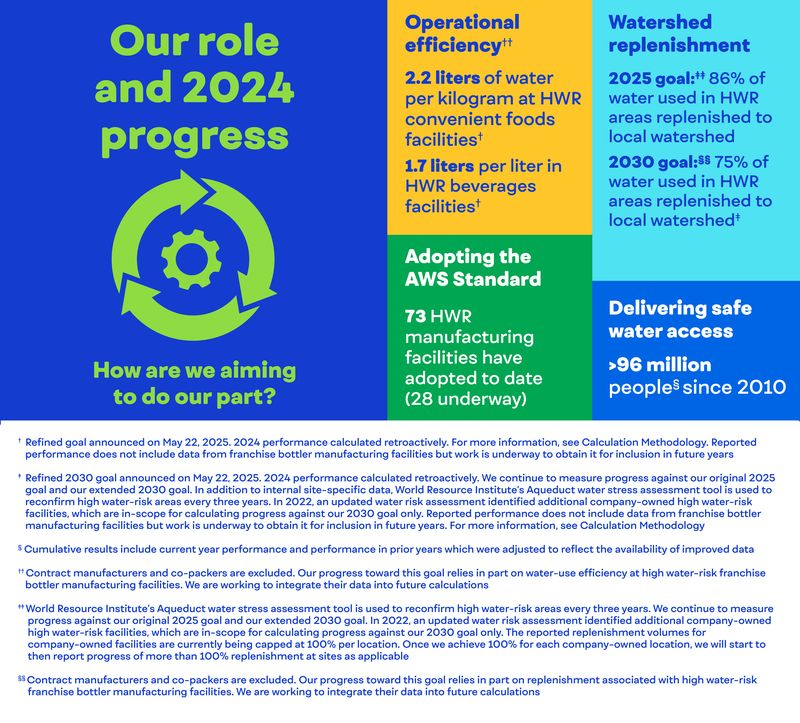

In 2024, our convenient foods manufacturing facilities used an average of 2.2 liters of water per kilogram of production at high water-risk facilities, while beverage production used an average of 1.7 liters of water per liter of production in high water-risk facilities. 6

In our effort to reduce our freshwater consumption, we are scaling innovative water treatment technology and no water usage technology in high water-stress areas for other PepsiCo sites around the world. These technologies include:

- Ingredient water capture : Since 2021, PepsiCo has been pioneering technology to capture the water in potatoes — made up of about 80% water — during the frying stage of chip production. We recover and treat to safe drinking standards the fryer vapor condensate from potato chip operations instead of letting it evaporate off as steam. In 2024 at our Pune, India foods site, we piloted a newer, more efficient edition of this technology. Using an air cooled heat exchanger instead of a conventional water cooled system, we optimized the fryer vapor, heat and condensate recovery without the need for cooling water.

- Water efficient potato chip processing : We expanded the use of new washing technologies at convenient foods factories in the U.S. in 2024. Two new tools, used in the peeling and slicing stages of processing potatoes, help us reduce the amount of freshwater needed by up to 30 percent.

- ReCon programs : Our Resource Conservation (ReCon) program continues to expand within our operations. The program helps employees identify low- or no-cost opportunities for energy and water savings at our manufacturing sites. 2,000 people were trained and 25 site ReCon Deep Dives were completed across the PepsiCo manufacturing network during 2024.

Progress

- During the year, we replenished 75% 7 of the water used in our company-owned manufacturing facilities in high-risk watersheds.

- At the end of 2024, we had 28 facilities in the process of adopting and 73 facilities that fully adopted the AWS Standard.

Challenges

- Bringing about long-term, permanent improvements to at-risk watersheds requires scale, partnership and engagement from all stakeholders in each catchment. Securing these is an ongoing priority as we pursue our water ambitions.

- Water stress and broader water-related issues are growing global issues, accelerated or exacerbated by the effects of climate change. Volatility driven by climate change requires intensive and agile planning to adapt our water strategy.

Water replenishment

Our 2030 replenishment goal builds on our 2025 goal, covering facilities not previously identified as high water-risk and expanding the goal to include HWR third-party bottlers. 4

In 2024, we replenished approximately 75% of the water we use in our company-owned manufacturing facilities in high-risk watersheds. 7 In total, global projects replenished approximately 24 billion liters of water. Because we cap each location’s water replenishment at 100% of its water use, 13 billion liters of this volume counts against our 2025 and 2030 replenishment ambitions. In 2024, we were working on 48 replenishment projects across the globe, including 16 projects launched during the year. New projects included:

- Stormwater Retention Ponds Project with The Nature Conservancy in the Florida Everglades : This project aims to improve stormwater pond performance in the Florida Everglades watershed by retrofitting ponds with sensors, weather forecasting, and adaptive controls to enhance and improve water quality, help mitigate floods, and restore more natural flows.

- Mokelumne River Watershed Project : Sacramento-San Joaquin River watershed in California : Together with Blue Forest, the World Resources Institute, and the Upper Mokelumne River Watershed Authority, this project focuses on restoring forest structure, composition, and function in over 2,000 acres of the Mokelumne Basin, part of the greater Sacramento-San Joaquin River system in Sacramento, California.

- Quechan Tribe Water Conservation Project : Colorado River Watershed Fort Yuma Indian Reservation : The Quechan Tribe Water Conservation Project in the Colorado River watershed on the Fort Yuma Indian Reservation in California strives to allow for the building of a new solar pumping station, retiring a point of diversion on the river, and improving water delivery infrastructure, which will improve water efficiency and reduce diversions from the Colorado River.

- Shea Island Channel Project : Sacramento-San Joaquin River watershed : A collaborative aquatic restoration project with Chico State Enterprises the Sacramento-San Joaquin River watershed in Redding, California, restored three side channels to improve river flow to sustain perennial flow and will also provide habitat for endangered Winter-run Chinook salmon.

Access to safe water

Since 2010, PepsiCo and the PepsiCo Foundation have helped more than 96 million people gain access to safe water through distribution, purification and conservation programs. 8

In 2024, the PepsiCo Foundation invested approximately $700,000 in safe water access programs, and it plans to continue to expand the reach of its safe water access program by providing grants.

In 2024, the PepsiCo Foundation launched VivaOliva, a program aimed at supporting regenerative agriculture and water conservation in olive farming practices in Jaén, a region in Spain facing economic hardship. Through VivaOliva, the Foundation provides smallholder farmers with training on regenerative agriculture practices, including compost fertilization, cover cropping and building infiltration trenches. These practices can help to enhance soil health and biodiversity, rehabilitate degraded lands, increase water efficiency and boost long-term profitability amid challenging economic conditions.

Taxonomy

- Water Efficiency

- Water Risk Tools

- Water Stewardship

- Water Risk

- California, United States

- Water Treatment

- Water pasteurizing