Zero Liquid Discharge (ZLD) Technology Separating the Brines into Dry Mineral Salts and Clean Water

Published on by Water Network Research, Official research team of The Water Network in Technology

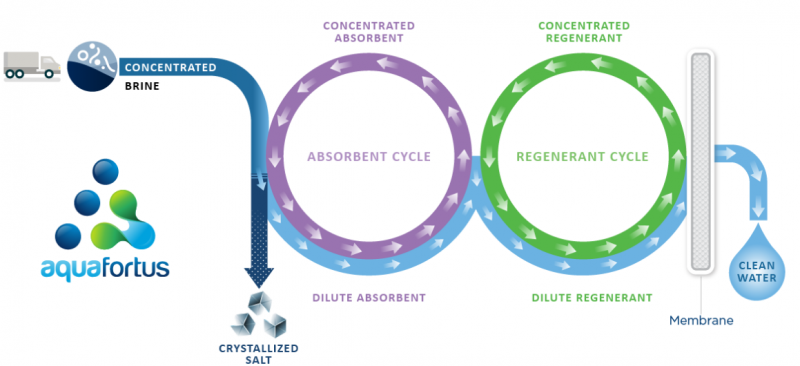

Aquafortus specialises in taking wastewater with high levels of salinity and through its patented zero liquid discharge (ZLD) technology separating the brines into dry mineral salts and clean water.

Image Source: Aquafortus

Aquafortus develops and holds multiple patents on non-thermal, continuous and re-generable ZLD technology. The Aquafortus ABXTM system is a novel liquid-to-liquid crystallizer that promotes the formation of salt crystals via a proprietary direct contact crystallization process using Aquafortus’ patented solutions. The ABXTM system efficiently reduces high TDS brines to salt and produces only clean water.

The Aquafortus ABXTM system works by a two-stage solvent exchange process with the patented “Absorbent” acting as a transfer medium for water. When wastewater brine contacts the absorbent, salts from the wastewater brine instantly crystallize. The “Regenerant” then regenerates the absorbent for continuous reuse in the system.

The Aquafortus ABXTM system will dramatically impact the economics of zero liquid discharge and promote its wider adoption.

Find out more: Aquafortus

Aquafortus Technologies start up signs USD $40 million deal with U.S. Oil and Gas Company

Aquafortus Technologies has signed an exclusive licensing agreement with Texas based PetroH20 Recovery. The agreement, valued at USD $40 million for the first three years and over USD $25 million annually beyond, is to deploy Aquafortus ’ patented zero liquid discharge technology in the U.S. oil & gas market.

Representative image, Source: Public Domain Pictures, Labeled for Reuse

Aquafortus specialises in taking wastewater with high levels of salinity and through its patented zero liquid discharge (ZLD) technology separating the brines into dry mineral salts and clean water.

It is an exciting opportunity for the company to break into the U.S. market, states Daryl Briggs, CEO of Aquafortus. “Every day U.S. oil and gas wells produce more than 58 million barrels of salty water and these numbers are growing. Our technology ensures the maximum recovery of clean, surface discharge quality water at less than half the cost of current solutions. This is an alternative that did not exist in the U.S oil and gas industry until our agreement with PetroH20” says Briggs.

While this is a significant opportunity for our patented ZLD technology the application isn’t limited to the oil and gas industry. Globally 900 million tonnes of wastewater is produced every day, in particular chemical refineries, dairy plants and coal fired power stations all generate significant volumes that require treatment.

“In addition to this, international ZLD regulations are creating very substantial opportunities as governments get serious about water pollution and its by-products, compelling industries that produce high salinity wastewater to install ZLD systems – this can currently cost on average between USD $20 - $900 per tonne of polluted water to dispose.

“Our technology uses 90% less energy than current state of the art high recovery technologies, reduces wastewater brines to solids, saving users in transportation and waste disposal costs and reduces OPEX by up to 60 per cent. Importantly, it also considerably reduces the emission of greenhouse gases from treatment of those polluting waters.”

“As the market is projected to grow from an estimated USD $4.67 billion in 2016 to USD $6.88 billion in 2021[1], we are very confident about our future,” adds Briggs.

The company is currently seeking funds from New Zealand investors prior to an international raise. Importantly, Aquafortus received its start through the Callaghan Technology Incubation Scheme.

“Activating innovation and accelerating commercialisation for a better New Zealand is why we exist,” says Callaghan Innovation’s Start-up Manager, Elena Higgison. “We’re proud to support Kiwi businesses that compete on the world stage, particularly with technology that has a multitude of applications once proven at scale. These products can be positively disruptive in terms of performance, reduction in process costs and environmental impacts.”

Source: Scoop.nz

Media

Taxonomy

- Reclaimed Wastewater

- Technology

- Wastewater Treatment

- Wastewater Collection

- Zero Discharge

- Brine Discharge Modeling & Analysis

- Produced Water From Oil & Gas Industry

- Oil Field Chemicals

- Zero Liquid Discharge plants

- Zero Liquid Discharge