Maritech CV

About

Chemical-free cleaning and biofilm prevention

We specialize in delivering the best available chemical-free solutions for:

- Cleaning of wet surfaces and reducing CFU's in:

- piping systems

- above-and underground storage tanks

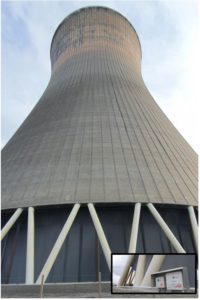

- cooling towers

- heat exchangers

- Fighting algae (and cyanobacteria) in ponds and recreational waterbodies

- Reducing corrosion and biofouling on submerged marine structures.

- Fight aquatic hypoxia and improve waste water recycling installations trough AOPs

Information

- Email: info@maritech.org

- Website: https://maritech.org/

- Phone: +32(0)474281303

- Location: Belgium

- LinkedIn: https://www.linkedin.com/in/biofilm-yves-peeters/

Taxonomy

- Membranes

- Catalysts

- Marine

- Activated Carbon

- Biofilm Sensors

- Non Toxic treatments

- Membrane Aerated Biofilm Reactor (MABR)

- Biofiltration