Aeration Control Package

Published on by Ashley Varga, Social Marketing Associate at Organica Water for Organica Water

CASCADE CONTROL

In a wastewater treatment facility, aeration is used to introduce oxygen into the water to create an environment where the micro-organisms can grow without any restriction and aids the decomposition of the organic contaminants and nutrients in the wastewater. To control the aeration process is extremely important to the operation of a plant. Aeration control provides the optimum amount of air to meet the oxygen demand of each zone while keeping energy consumption as low as possible.

AERATION CONTROL PACKAGE BENEFITS

12% aeration cost savings

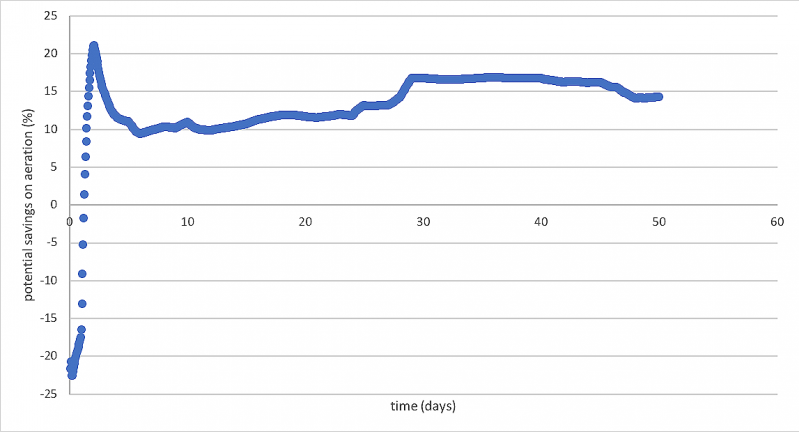

Potential savings on aeration in an overloaded facility compared to conventional control systems where a fixed airflow is kept in the whole reactor, applying higher-level controls (DO [dissolved oxygen] and even ammonium control) and dividing the system into multiple segments can result in considerable savings in aeration for biological treatment. In a recent case study, a 12% reduction in the air was determined when using a higher level of control compared to the original dissolved oxygen control. Compared to the 60-80% operating cost that comes from aeration in a traditional plant, this 12% savings coming from Organica’s digital upgrade is a significant reduction.

Additional ammonia monitoring

Ammonia control in an overloaded plant is extremely important; when a plant is overloaded, there’s little to no room left for failure. We have to make sure that the effluent ammonia concentration is kept within limits and just the right quantity of air is used for the treatment process. In this case, additional ammonia monitoring and ammonium-based airflow control need to be implemented in order to keep the plant effluent within these limits.

Control loop software

Applications with two or more stages are more difficult to control with a single control loop. This is due to large overshoots and lags in the system. The solution is a cascade of two or more control loops, each with its own input. This makes the control system more robust and precise and is at no additional cost to operators.

DATA EVALUATION AND DIGITAL SERVICES

Through data evaluation, we’re able to track the current conditions of a facility compared to the historical values. This allows us to determinate whether there is additional room for savings and if there could be an improvement on aeration by changing the operational set points. This requires a stream of continuous data from the plant, in order for us to recalculate the best operational scenarios and track the health of biology and sensor performance.

Organica’s Digital Service combines decades of experience and advanced Digital offering, designed to optimize facility performance. Digital services offer a real-time data connection. Through this, we can calculate the achieved savings on aeration and show these savings on a dashboard, where we can specifically see KPIs (Key Performance Indicators), e.g. how much water has been treated per Nm3 air and compare it to past values.

Digital services have enabled the right level of additional sensors and automation, along with continuous effluent monitoring and process supervision to calculate the best aeration savings possible for the plant.

Media

Taxonomy

- Wastewater Disposal

- Wastewater Use

- Reclaimed Wastewater

- Wastewater Treatment

- Wastewater Collection

- Process Control

- Control Systems

- Water Hammer protection

- Water Control

- Wastewater Treatment Plant Design

- Water & Wastewater

- Water & Wastewater

- Water & Wastewater

- Water & Wastewater

- Wastewater Treatment Chemicals and Consulting

- Wastewater engineering