Control & Instrumentation

Published on by Trudi Schifter, CEO and Founder AquaSPE for Organica Water

As part of its Digital Services, Organica supplies and installs highly automated control software, custom programmed to operate the wastewater treatment plant (WWTP) efficiently, while also allowing for seamless operation. Organica utilizes a PC-PLC based process control system, integrating the acquisition, display, and storage of operational data, as well as the input and application of operational variables.

The control and management of the Facility relies on the data gathered from the sensors and probes installed in the WWTP, provided by either Organica or a third party. The flow of wastewater is measured by electromagnetic meters and level indicators, while the optimization of energy consumption requires data from dissolved oxygen probes linked to variable speed drives controlling the blowers. Pump capacity is regulated via variable speed drives and electromagnetic or pneumatic controllers which regulate valves. All equipment is controlled by a PLC, which monitors their status through feedback channels and displays it on the application program available from an online interface.

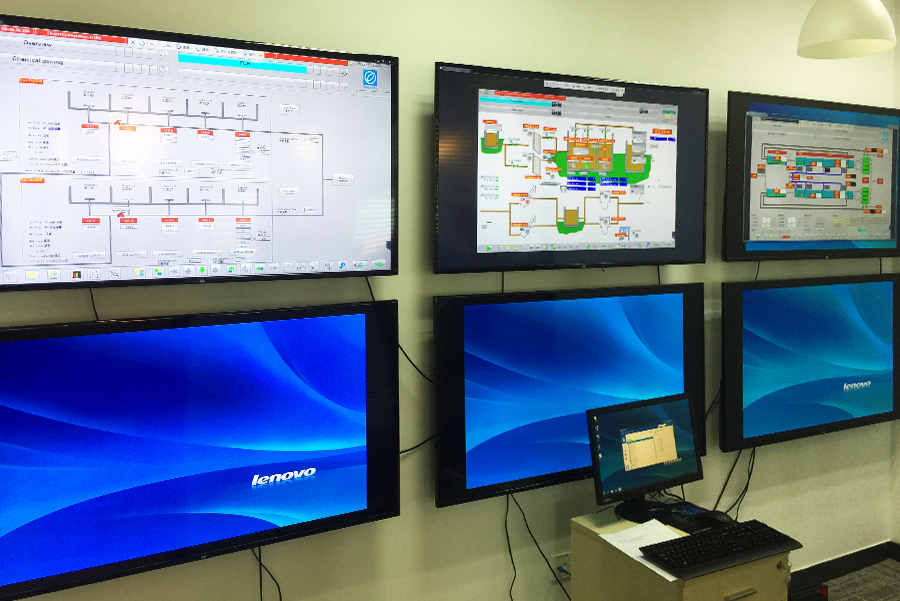

The process control software provides an easy-to-use graphical interface for operator interaction, ensuring the secure operation of the entire treatment plant. The operational savings from this high level of automation are significant, as with this level of sophistication facilities require very few personnel for safe operation. In addition, the ability to establish secure online connections enables Organica engineers to provide clients with an Operational Supervision service. Using the online interface, engineers can remotely view, evaluate, and provide input to optimize WWTP operation.

ORGANICA WATER’S DIGITAL PLANT PERFORMANCE CENTER

In today’s challenging and ever-changing wastewater industry, when private companies partner with wastewater facility owners and operators it can enable more successful operation. With increased pressure on facility owners and operators around the world to deliver clean effluent water – sometimes water cleaner than the river they are discharging to or clean enough for reuse in irrigation or industrial processes – partnering with private companies can really add value.

To meet these challenges, Organica provides the necessary hardware, software, and expertise for partnering with wastewater facility owners and operators. Here at Organica, we pride ourselves on our ability to provide value to our clients.

Along with integrating current hardware, Organica determines the optimal number of additional sensors and automation/controls to both efficiently monitor and enhance facility operations. In addition, through machine learning and artificial intelligence, Organica introduces software to connect and analyze wastewater data, while continuously monitoring and providing reports, alarms, and trends to experts. Organica’s Plant Performance Centers in Budapest and Shanghai allow us to analyze alerts and work with operators to predict, prevent and prescribe solutions to achieve operational success for our partners.

The Plant Performance Centers are innovation incubators that assist with the operation and maintenance of plants around the world. Each facility is unique, and our experts work with operators to determine the right level service and to develop a common set of success criteria specific to each plant. This type of partnership gives your staff extended reach into wastewater expertise and the necessary support for any situation.

Media

Taxonomy

- Water Treatment & Control

- Process Control

- Control Systems

- Remote Sensing & Data Analysis

- Database Managment

- Database Software

- Remote Monitoring & Control

- Data & Analysis