How to Fix a Problem of Sludge Bulking in a Waste Water Treatment Plant?

Published on by Mesi M. in Technology

We are running a small industrial wastewater treatment plant with capacity of 3000 m3/day for a food processing unit.

We are using the activated sludge wastewater treatment process and facing the problem of sludge bulking for the last month.

We find out that the reason is low level of dissolved oxygen.

Can someone explain to me how we can fix this problem and how to avoid these issue?

Taxonomy

- Industrial Wastewater Treatment

- Sludge Treatment

- Sludge Management

- Waste Water Treatments

- Wastewater Treatment

- Waste Water Treatment

- Sludge Treatment & Management

29 Answers

-

you can install dissolve oxygen sensor connection with variable frequancy drive VFD for the aerators or SCADA system also check MLSS level

-

Sir.....easy to fix...just add a very small amount of our product - Solutek. Been around for 20 years .... we have huge amounts of data ... fully organic product.

See website --- www.soleco-technology.com

Talk to us and we can help....email: pettman@soleco-technology.com

Hugh.

-

I don't know what you mean by "sludge bulking", but low levels of dissolved oxygen are fixed by introducing oxygen, generally by aeration. Can you please explain what you mean by sludge bulking?

-

Simple....add small quantities of our 100% fully organic solution - SOLUTEK.

this has been working in waste water treatment plants for large twosn for 15 years and in small systems for 20 years...after a short time of treatment...no more sludge and after just 5 days, no more odor.

-

Estimado mesi, es Necesario conocer La Causa, bajo esta premisa un bajo nivel de oxigeno no obedecen siempre a la misma sino comprenden el efecto.

con esto te quiero decir que aunque tu sistema trata unas aguas que pueden parecer inofensivas, estas pueden llevar sobrecargas, toxicos o causan una especie de problema que a primera vista no se ve.

mi recomendacion:

revisar relacion F/M

revisar concentraciones de grasas, sulfuros o cualquier otra sustancia que ya identificada pueda causar tu problema.

Alguna vez estuvo tu planta estable?, tienes datos de esta misma y podrias retroalimentarnos con el seguimiento de la misma.

el oxigeno por si solo no te muestra el problema es solo un sintoma que mas has visto que ha cambiado?

quieres mas consejos,

puedes enviarme el seguimiento a tu sistema a o.lparada@gmail.com,

con gusto puedo ayudarte.

saludos!!

-

The Water Network research team has consolidated an answer to the above question.

Further input from members is welcome and appreciated.In sewage treatment air is passed through a mixture of sewage and old sludge. The air is necessary for microorganisms to decompose organic components.

As new sewage enters the tank, treated sludge exits. For this to work, the sludge should be settled so that supernatant can be further treated.

If sludge does not separate and settle in sedimentation tanks and remains “floating”, sludge bulking has occurred.

Filamentous bacteria are the most common cause of sludge bulking.

Filamentous microorganisms grow in long strands with bigger volume and surface than flocs so they settle very slowly.

Excessive filamentous development is often caused not only by environmental conditions but also by the influent itself which may contain food for bacteria.

Microscopic examination determines which type of filamentous bacteria is present and determines the treatment that should be applied.

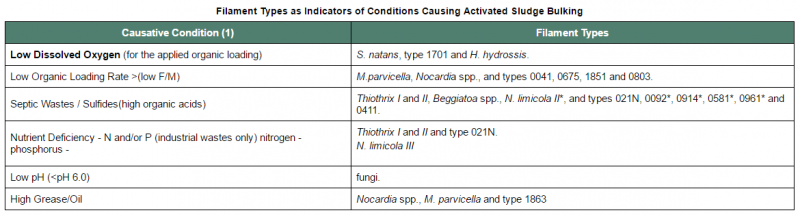

The following table shows the causes of filament growth :

Table 1: Filament Types as Indicators of Conditions Causing Activated Sludge Bulking

Table 1 source: dec.ny.gov/chemical/34373.htmlLow Dissolved Oxygen Concentration

The necessary dissolved oxygen (DO) concentration to prevent bulking does not remain constant all the time. It is a function of the F/M rate. The F/M rate (food to microorganism) is a control number for determining the proper number of microorganisms for the system.

As the F/M rate increases, more oxygen is used and needed to maintain the aerobic conditions inside the flocs. The dissolved oxygen concentration should, therefore, be increased to keep the oxygen diffusion into the flocs.

Recommended DO concentration for most wastewater plants (F/M up to 0.5) is 2.0 mg/l. (This concentration should be measured at the head-end of a plug-flow system, not the back-end.)

To control bulking due to low DO, the aerations basin DO concentration and mixed liquor suspended solids (MLSS) concentration should be raised.

Increasing MLSS will decrease the F/M.

However, low F/M may cause filamentous bulking.

Filamentous bulking is treated my decreasing the MLSS which should be done with caution because it may decrease nitrification and cause more waste sludge to be produced.

Additionally, low F/M can be adjusted with some of the methods which do not affect the MLSS: compartmentalization of aeration basins; fed-batch operation; intermittent feeding of wastes; and use of a selector.

Septicity

Wastewater becomes septic when organic matter decomposes and forms a foul smell due to the absence of free oxygen.

If wastewater is severely septic, it will produce hydrogen sulfide, turn black and give off a foul odor.

Septicity in a sewage system occurs when microorganisms use up all the dissolved oxygen and nitrates in the sewage.

Without oxygen, anaerobic conditions develop and bacteria reduces the organic compounds to sulphur and sulfide. Then sulfate- reducing bacteria utilize sulfates to form sulfides which increase the filament growth.

*Read more about conditions in which septicity occurs and about how to reduce septicity here.

Waste septicity is treated by preaeration (which releases odors), by chemical oxidation (chlorine, hydrogen peroxide or potassium permanganate), by chemical precipitation (ferric chloride), or use of sodium nitrate in the collection system as an "oxygen source".

Low Nutrients

Lack of nutrients such as nitrogen and phosphorous can limit activated sludge growth.

Nutrient deficiency can be prevented by keeping the concentrations in the effluent water at 1.0 mg/l of total inorganic nitrogen and 0.5-1.0 mg/l of ortho-phosphorus.

Otherwise filamentous bulking and foaming may occur.

Low pH

The pH in the aeration basin should be kept at 6.5 – 8.5.

Lower pH can induce the fungi to grow and cause fungal bulking.

The pH should be adjusted using caustic, lime or magnesium hydroxide.

Physical and chemical methods to control the filaments:

Polymer Addition

Synthetic, high molecular weight, cationic polymers (with or without the anionic polymer) can be added to control the filaments.

They are added to MLSS which leaves the aeration basin or to the secondary clarifier center well.

Polymers can be expensive, even $450 per million gallons, but they do not increase the sludge production too much.

Inert Material Addition

If lime of ferric chloride are added they coagulate and precipitate the activated sludge and make it settle easier.

However, their usage may greatly increase the sludge production.

*Adding flocculants if the problem is caused by filamentous bacteria only treats the ‘symptom’ and is not efficient in the long run.

Chlorination

Chlorine and hydrogen peroxide can control the filaments.

Chlorine is fairly cheap and easily available so it is most commonly used.

The chlorine dose should be lethal to the organisms only on the surface of the floc so that chlorination damages the filaments on the surface of the floc while leaving the floc inside undisturbed.

If the problem is not filamentous, chlorination can actually bring more damage.

Chlorine is applied from a chlorinator using chlorine gas feed or as a liquid hypochlorite.

It is crucial to determine the right spot for chlorination: where sludge is concentrated, raw wastes are at a minimum, and at a point of good mixing.

Chlorine should NOT be added to the aeration basin since it will cause the flocs to disperse and may damage the system.

Chlorine dosage should be started at low concentrations and gradually increased until it becomes effective.

The chlorination frequency is the function of the relative growth rates and the efficacy of killing the filamentous and floc-forming organisms.

Chlorination is not too efficient in controlling sludge bulking. It only gets rid of filament extensions which will regrow after the chlorination is over.

Related documents:

-

Please take a look at our web site. www.soleco-technology.com

We have been removing sludge with our product for nearly 20 years. Our product is 100% ORGANIC.

Please email us and we can discuss.

Hugh.

-

crowdsource challenges and solutions via the Marketplace

You may find solutions to your challenge or even post this challenge and get solutions via an exclusive infrastructure community, the Marketplace of the Innovation Interchange https://www.innovationinterchange.com/products/marketplace

When facing intractable challenges, owners and operators of infrastructure assets can find solutions from across the globe via the technology Marketplace. Register free online and connect with other organizations as you crowd source challenges and solutions.

-

Dear every one thanks for putting efforts in answering my question. As I said the system is having low oxygen, we have increased the oxygen level and can see some difference. Thanks once again for your wonderful answers and comment. Keep smiling.

-

There are several reasons for sludge bulking and many of them have been reported by colleagues. One question arises: are you sure that it is bulking sludge? Have you loked at the microscope. If yes, fine and you can use ideas already done.

-

MEssi, read this website, it may help http://www.meniscus.co.uk/page.php?article=964&name=Bulking+In+The+Activated+Sludge+Process

-

Bulking can be said to have occurred in activated sludge plants when the sludge does not settle easily and has an excessive volume. high F:M ratio requires a high DO concentration for effective treatment of the BOD load. However at low DO concentrations and at high F:M ratios excessive filamentous growth may occur leading to bulking. Bulking due to low DO can occur in a short space of time. A correction mechanism could be to increase the DO in the aeration tank.

-

I am not sure but I think idea may work, by the addition of Acid if the treatment channel is acid resistant.

-

Hi Mesi What kind of wastewater treatment plant? I mean what is the system?

-

Control of Bulking Sludge

Another issue in the activated sludge process is sludge age. If it is too old, filamentous bacteria develop, and prevent sludge from settling properly. You should be able to find plenty of reference material about testing sludge age and interpreting the results.

Some people add hydrogen peroxide to control the filamentous bacteria, but this is strictly a stop-gap measure.

Dissolved oxygen could be a factor. If a septic condition occurs, the bacteria go to the nitrate and nitrite compounds for oxygen, releasing gas bubbles that can buoy the sludge.

Good luck. let us know what you come up with.

-

Dear Mr. Mesi, You need to maintain a slope in the sludge drain, as sludge sedimentation slowly clogs the drainage if no acceptable slope is available to enhance the flow and reduce clogging of drains. Said

-

There could be multiple reasons for sludge bulking. The fact that your problem is starting at the start of colder period, would suggest the presence of filamentous bacteria such as microthrix parvicella or nocardia. It is recommended to do a microbiological identification. Once identified, there are specific treatments to reliably solve and prevent reoccurence of bulking.

-

there are some bacteria called free-flow bacteria...by seeding these bacteria in your sludge ....can improve the microbial activity of your sludge....and can solve your problem...

-

How to fix a problem of Sludge bulking in waste water treatment plant

Sludge bulking is cumulation of suspended solids, not connected to low DO. WHile it is true that sludge(both organic and inorganic) consumed DO there's no sense to connect the low DO and the sludge bulking. In principle, you will have your sludge through time and the thing to do is to remove it. It will be easy to remove such by identifying if your sludge is cationic or anionic then you can add the sufficient amount of specific coagulant then filter it out.

Thanks. I hope Im able to help.

-

Your query is much too general to respond to in any meaningful way. There are many options and technologies available but without some idea of the characterization of the industrial waste stream it is not possible to suggest anything. The basics to even open a discussion would be: 1. Characterization of the wastewater ( hydraulic and chemical/biological/physical characterization? 2. What is the receiver and what are the effluent discharge criteria? 3. Where is the project? 4. Is this a new facility of a modification to an existing one?

-

lyseconcept has developed a scientific paper that defines that: anaerobic does not exist on earth, anaerobic can not exist on earth. for such an environment is created that should not be surrounded by a medium-Aerobic-. and the temsp expressed in "period of time" is long enough to allow him to date info on severe create stabilize perpetuate. out this is not the case and the conditions present in a wastewater system by the flow of a continuous flow. I forward this document to anyone wishing to inform. Sanitation was there not long ago a simple and natural and final thing. Today it is no longer, why? because the notion of 'BIOLOGY' no longer exists

-

It should be known that the principle says “activated sludge” does not exist. From the moment when a Biological element becomes - mud - it loses this biological characteristic. Your diagram describes Ci above shows it perfectly since those Ci pile up. In a circle closed in putrefaction there is no more oxygen. More oxygène=plus of vie=plus of micro alive oragnisms: it is a dead product. And more you will try to bring oxygen there by brewing it (activated sludge) and more it will oxidize. Two years of studies on these problems enabled us to define this theory. In more one essential concept does not appear at all in your talk: the biological aspect of the effluent. you seek a 'biological' solution with an element which lost this concept. Reassure it is the world case of the treatment of waste waters. The Biological cleansing solves all these problems even further while going since after the treatment the water rejection becomes productive because it is sent on a vegetalized discharge system http://www.lyseconcept.fr, http://www.creabpa.fr E-mail: lyseconcept@gmail.com for a personalized proposal

-

Operational causes of bulking

Some of Operational causes of bulking include

1. low dissolved oxygen in the aeration tank

2. insufficient nutrients: Especially quantity of nitrogen and phosphorus important, also absence of trace element cause bulking.

3. widely varying organic waste loadingbut the limited dissolved oxygen has been noted more frequently than any other cause for sludge bulking. If the problem is due to limited D.O. Aerating equipment should operate at full capacity. At least 2 mg/L of dissolved oxygen in the aeration tank (under normal loading conditions) should be maintained.

-

Hello, Please send a water analysis before and after treatment. Also send a P&ID with tank volumes,aeration system and temperatures. What colour is the sludge? Do you have DO probes? Kind regards Rick Wadley Vortex Water

-

To cope with a solution for a low DO Bulking

Without a complete overview about your wwtp, but only on the base of tipology of your cronic bulking and wastewater process, I would like to say that could be an high level of soluble COD and high F/M. So, you have face (one or more) to this possible actions:

1) Increase MLSS with a lower flow of waste sludge, paying attention to SS out of secondary clarifier.

2) Make possibile a differentiation of level oxygen distribution by creating an aerobic selector (more DO) able to face the first high level of organic load.

3) Make possible obtain a lower organic load with a different pretreatment of wastewater

4) Make possible obtain an higher DO level by facing an upgrading of aeration system.A more depht analysis on load data and on Microfauna and Filamentous Bacteria may be more suitable to understand how your bioreactor work..

-

Another vote that low oxygen is BOD, COD, DO related, another angle is that either a new group of bacteria have gotten in somewhere, or as is happening now, check for glyphosate, the main ingredient of Roundup now found commonly in foods, it has a detrimental effect on beneficial bacteria and can tip the balance on bacterial populations quite easily, very potent and for example is preferential to Salmonella.

-

Low aeration basin dissolved oxygen

Low aeration basin dissolved oxygen (DO) concentration for the applied organic loading (F/M) leads to filamentous bulking by several filaments . The required aeration basin DO concentration to prevent "low DO bulking" is not a constant, rather, is a function of the F/M rate . Simply, higher bulk DO is required to prevent the growth of these filaments as the F/M increases, due to faster oxygen use within the floc at higher F/M, oxygen depletion inside the floc, and the need to maintain aerobic conditions in the interior of the floc. A higher bulk DO concentration increases the diffusion of oxygen into the floc interiors.

-

Sludge handling in a WWTP

Hi,

there is no short answer to your problem. In order to understand the problem, will need to know the process used in this particular WWTP. Is it membrane based or is it anaerobic digestion...? What is you operating MLSS and is BOD, COD, DO and tank sizes? How often do you waste the sludge and how much?

So all these details needed before proposing any solutions.

-

Mr. Messi, may I know your wwtp diagram flow briefly? Thanks